Whey-contaiing food product and method of deflavoring whey protein

a technology of whey protein and food products, which is applied in the field of deflavoring whey protein materials, can solve the problems of limited acceptance by consumers and significant off-flavors, and achieve the effects of reducing solubility, and maintaining the solubility of whey protein conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

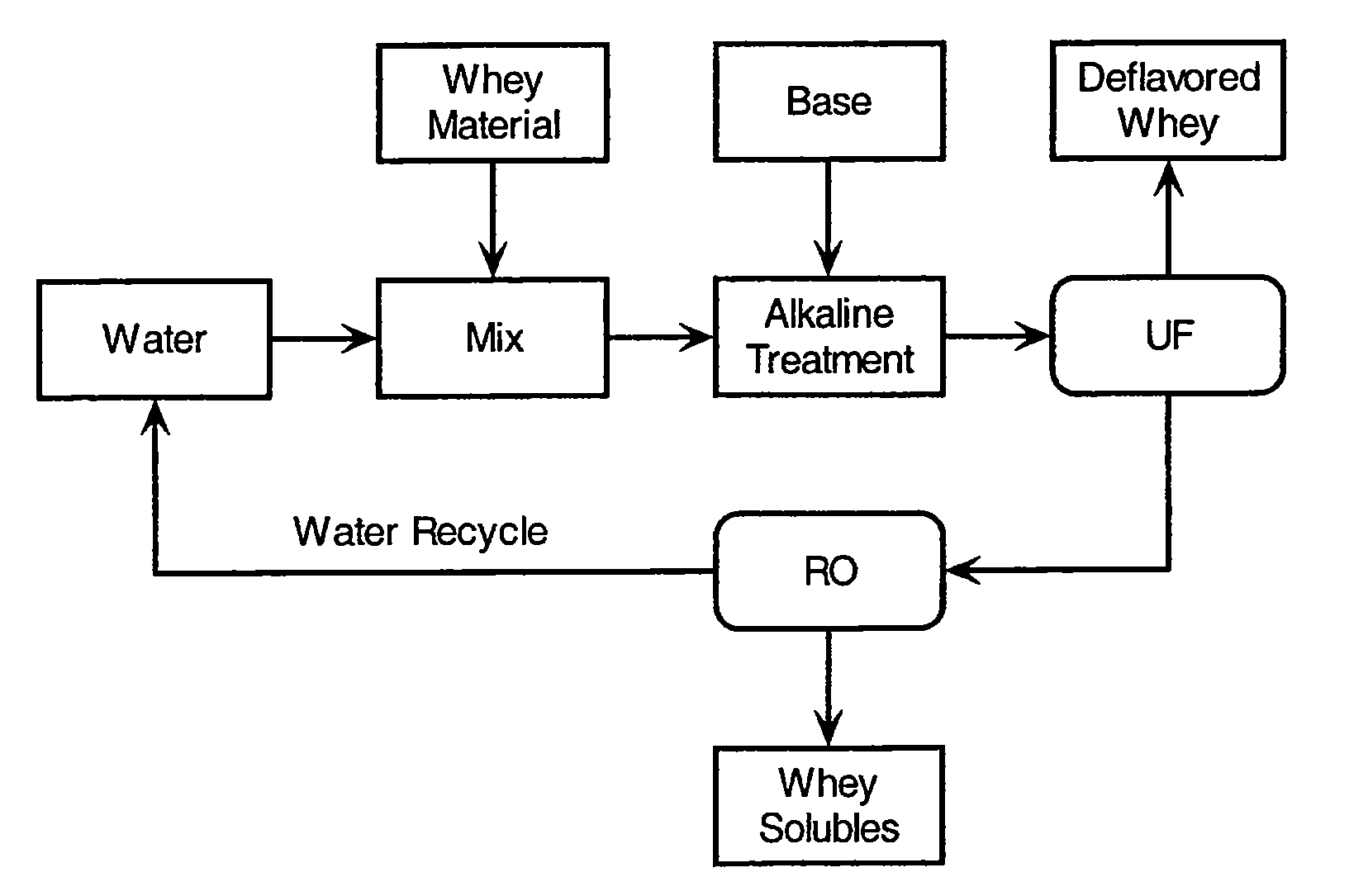

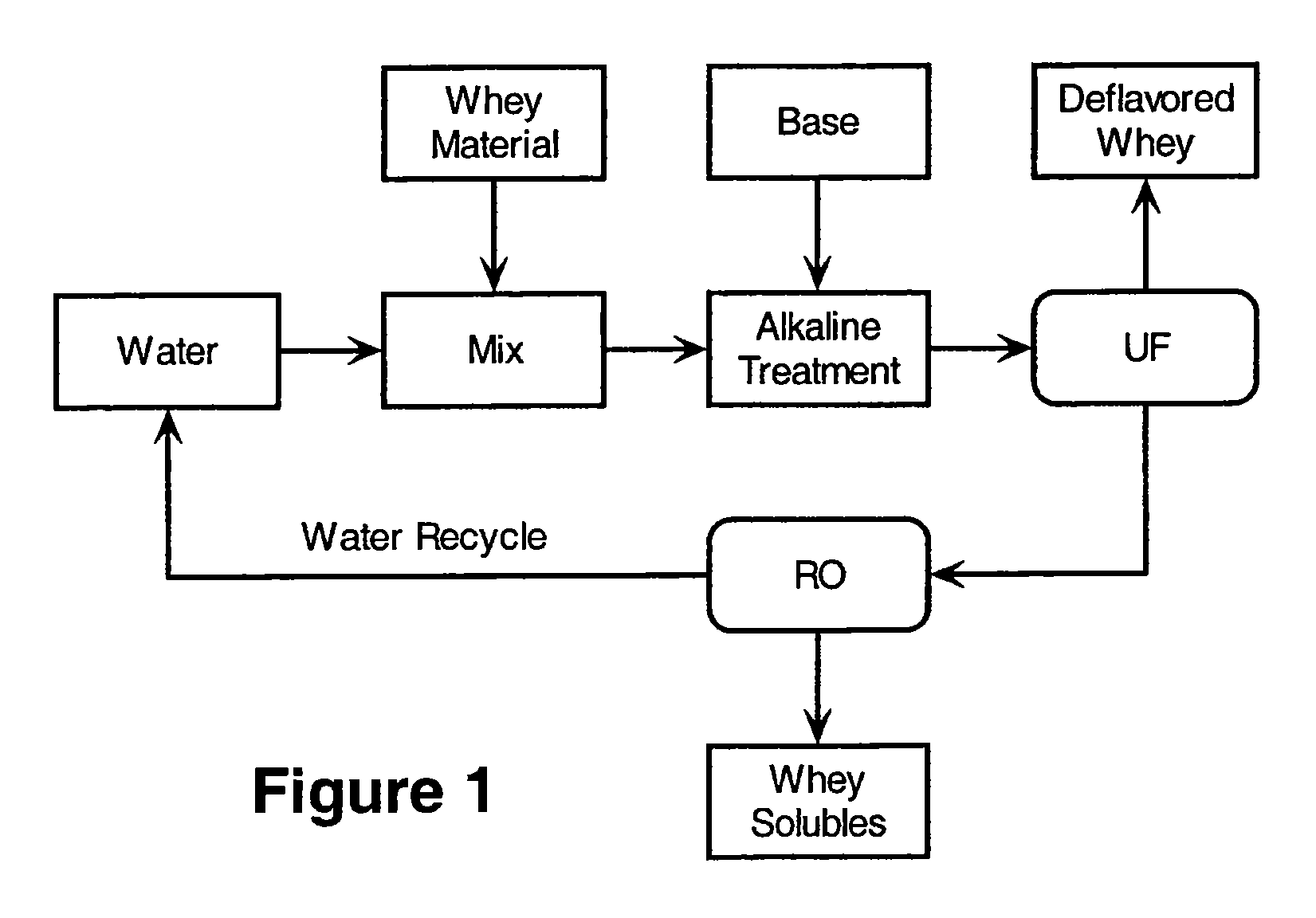

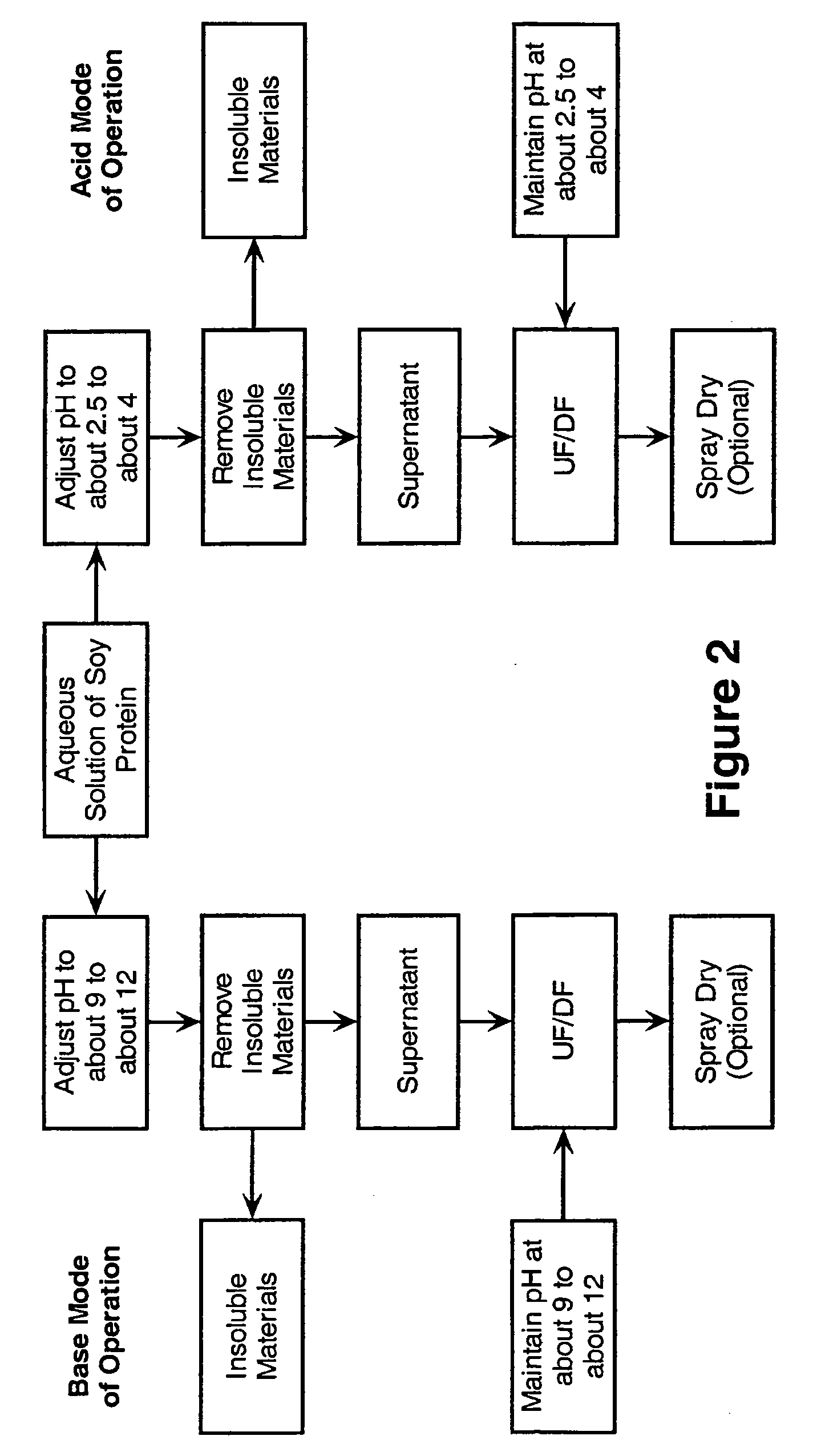

Method used

Image

Examples

example 1

[0049] Whey protein concentrate (30 lbs. of WPC34 (34 percent protein; Leprino Co., Denver, Colo.) was hydrated with water (170 lbs.) in a mixing tank with vigorous mixing at a temperature of about 120° F. Once hydration was complete (generally within about 10 minutes), the pH was adjusted to 9 using 1 N NaOH. The pH-adjusted solution was then diafiltered through a ultrafiltration membrane (spiral wound type with 10,000 molecular weight cut-off). Diafiltration was continued for an equivalent of 5 wash cycles (each wash defined as the amount of permeate collected equal to one-half of the initial batch size). The pH was maintained at about 9 during the ultrafiltration / diafiltration process. Once diafiltration was completed, solids in the retentate was concentrated to about 20 percent and citric acid (1%) was added to adjust the pH to 6.0. The resulting slurry was freeze dried to obtain a solid deflavored whey protein material. The deflavored whey protein material was found to contain ...

example 2

[0052] The deflavored whey protein sample prepared in Example 1 was used to prepare a high protein beverage. The following formulation was prepared: 87.3 percent water, 7.0 percent deflavored whey protein, 2.5 percent salt, 2.5 percent sugar, and 0.2 percent peach flavors. The dry components were first blended and the hydrated in the water using an overhead mixer. Once hydration was complete, the flavor component was added. Stabilizers such as pectin and carrageenan could be added if desired to adjust final product viscosity to the desired level. Sugar could be replaced to high corn syrup or other natural or artificial sweeteners if desired. Based on taste evaluation using a trained taste panel, the beverage was considered excellent with regard to overall mouthfeel and flavor with no off-flavors detected. The resulting beverage delivers about 13 g whey protein per 250 ml serving size.

example 3

[0053] This example illustrates the preparation of deflavored whey protein from sweet whey. A clarified sweet whey (also known as rennet whey or cheese whey) was obtained from a cheese making process. The sweet whey contained about 12 percent protein, about 78 percent carbohydrates, and about 1.1 percent fat on a dry basis (remainder mainly ash). The sweet whey had been clarified using centrifugation to remove fat, cheese fines, and caseins, thereby significantly reducing fouling and increasing flux rates in the subsequent ultrafiltration step. About 700 pounds of the sweet whey was heated to about 120° F. in a jacketed reactor; the pH was then adjusted to about 7.5 with the addition of 1N NaOH. The alkalized whey was then continuously concentrated using ultrafiltration / diafiltration as in Example 1 using a UF sprial membrane with a 10000 molecular weight cutoff. Retentate was recirculated and maintained at about 5 percent solids. Once the solids in the permeate reached about 50 per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com