Photoelectrochemical device

a photovoltaic and photoelectrochemical technology, applied in photovoltaic energy generation, electrical equipment, electrolytic capacitors, etc., can solve the problems of affecting the efficiency of the device, and the corrosion of pec cells' metallic components, etc., to achieve cost-effectiveness, low cost, and without loss of effective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Having broadly portrayed the nature of the present invention, embodiments thereof will now be described by way of example and illustration only. In the following description, reference will be made to the accompanying drawings in which:

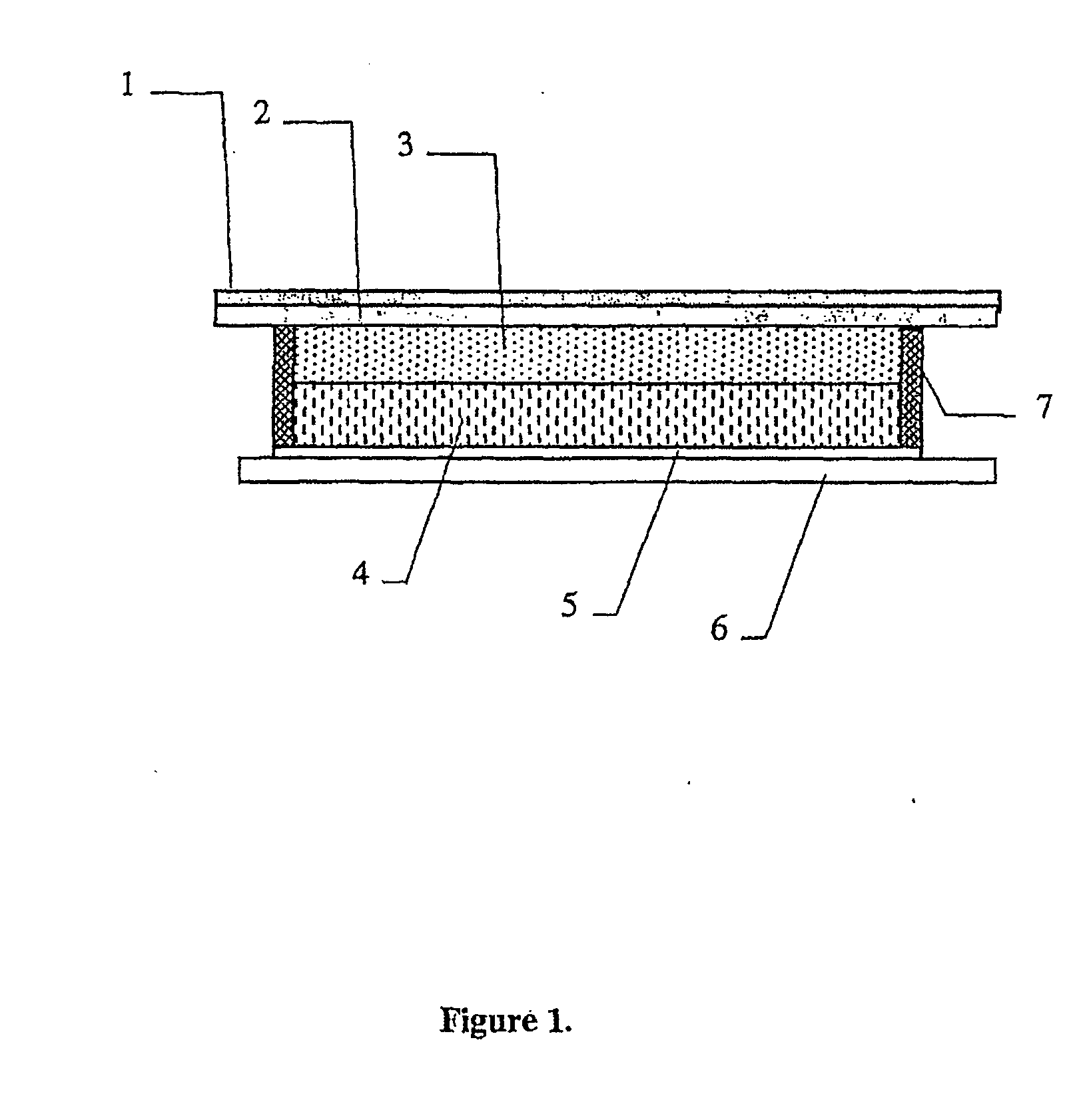

[0032]FIG. 1 is an enlarged cross sectional view of a PEC device formed in accordance with one example of the invention.

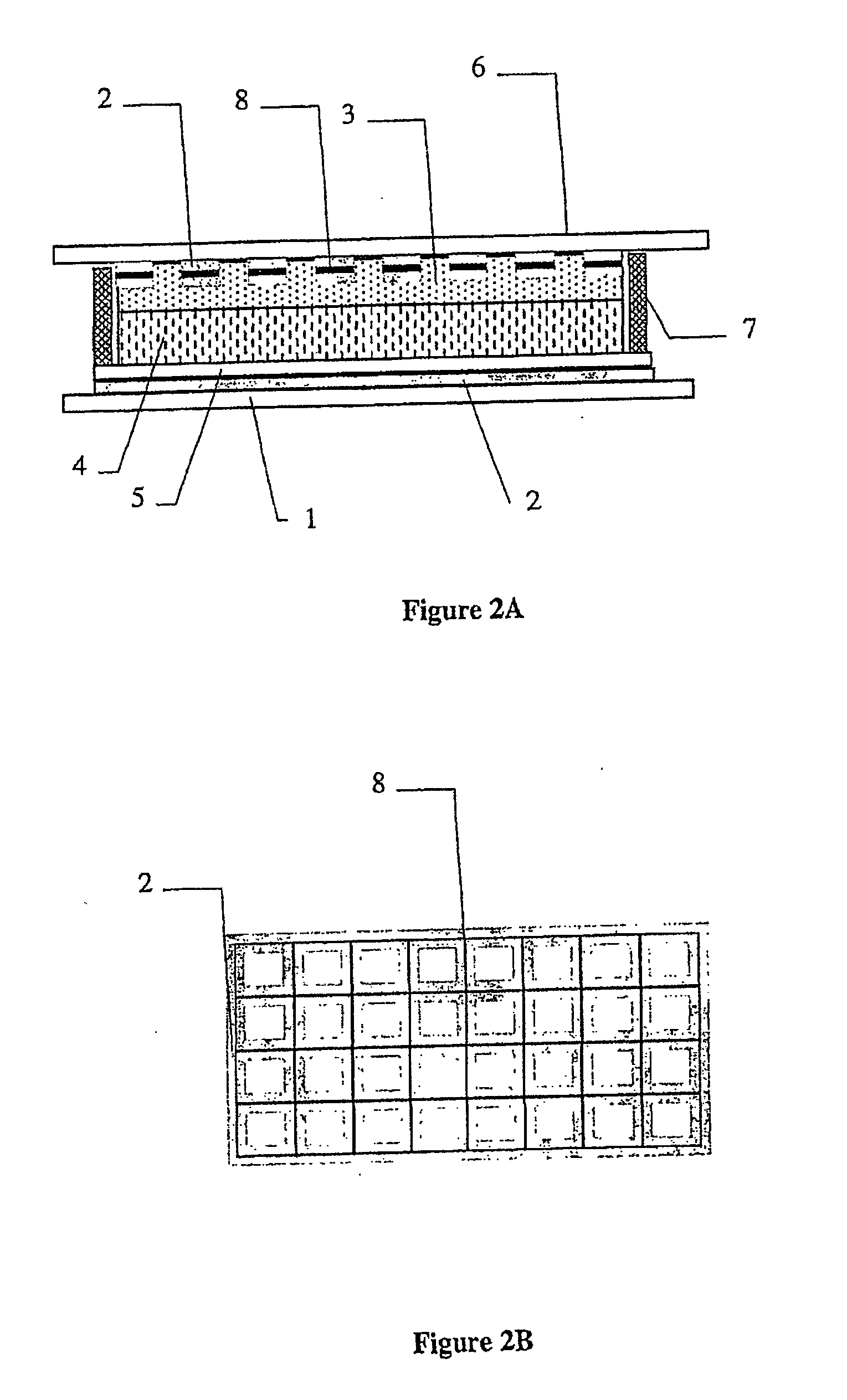

[0033]FIG. 2A is an enlarged cross sectional of a PEC device formed in accordance with another example of the invention.

[0034]FIG. 2B is a diagrammatic view of a stainless steel mesh protected by a TiN coating.

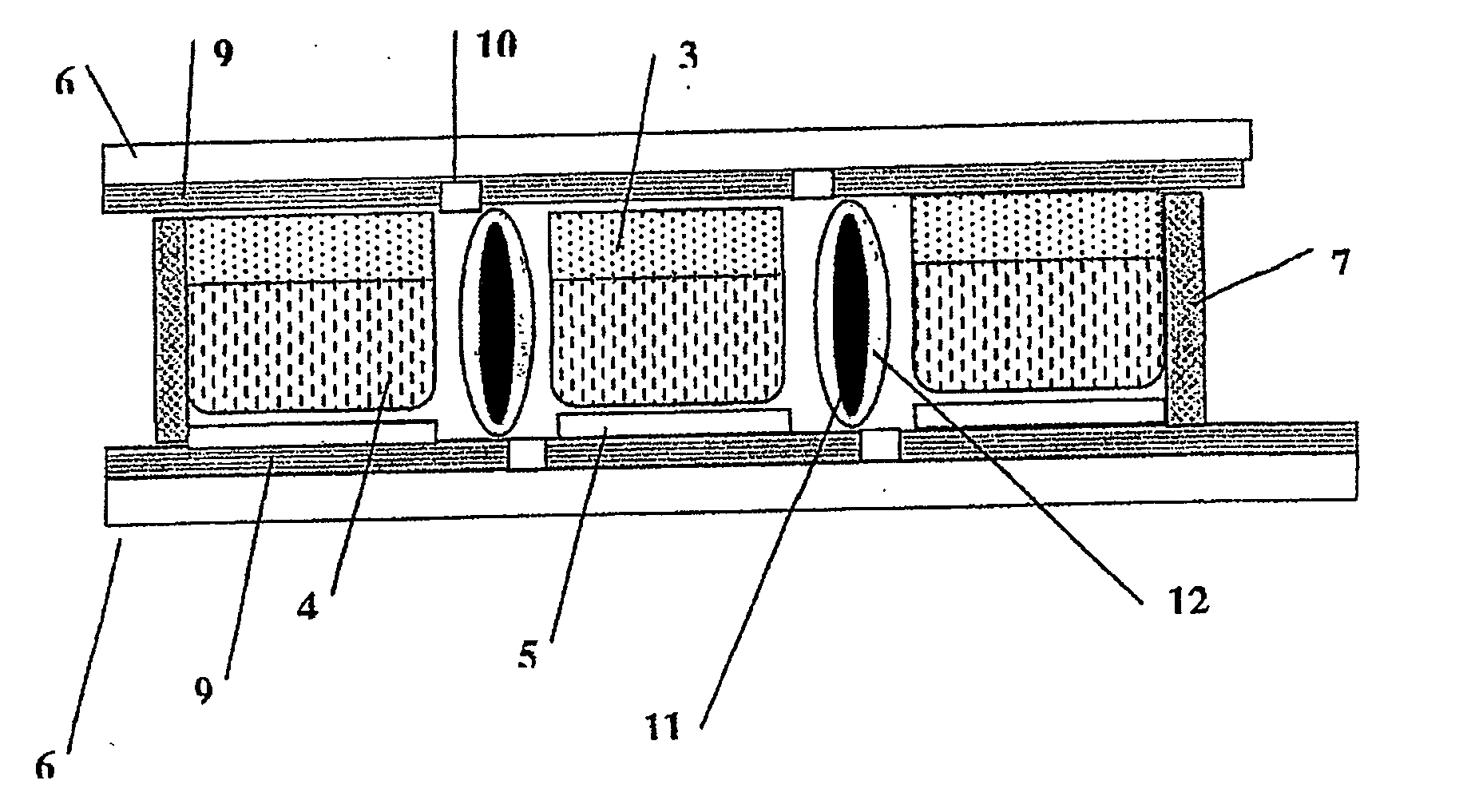

[0035]FIG. 3 is an enlarged cross sectional of a PEC device formed in accordance with further example of the invention.

[0036] Referring to FIG. 1 the working electrode substrate comprises Stainless Steel foil 1 protected by TiN coating 2. Working electrode 3 (dye sensitised TiO2) formed on TiN coating (3 microns thick, filtered plasma deposition). The counter electrode 5 (thin dispersed Pt catalytic layer) of the dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| electrical current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com