Solid polymer membrane-type water-electrolysis apparatus

a water-electrolysis and membrane-type technology, applied in the field of solid polymer membrane-type water-electrolysis apparatus, can solve the problems of limited storage volume of hydrogen and oxygen, limited transportation and storage of apparatus, and increase in size and weight of the entire apparatus, so as to achieve convenient washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

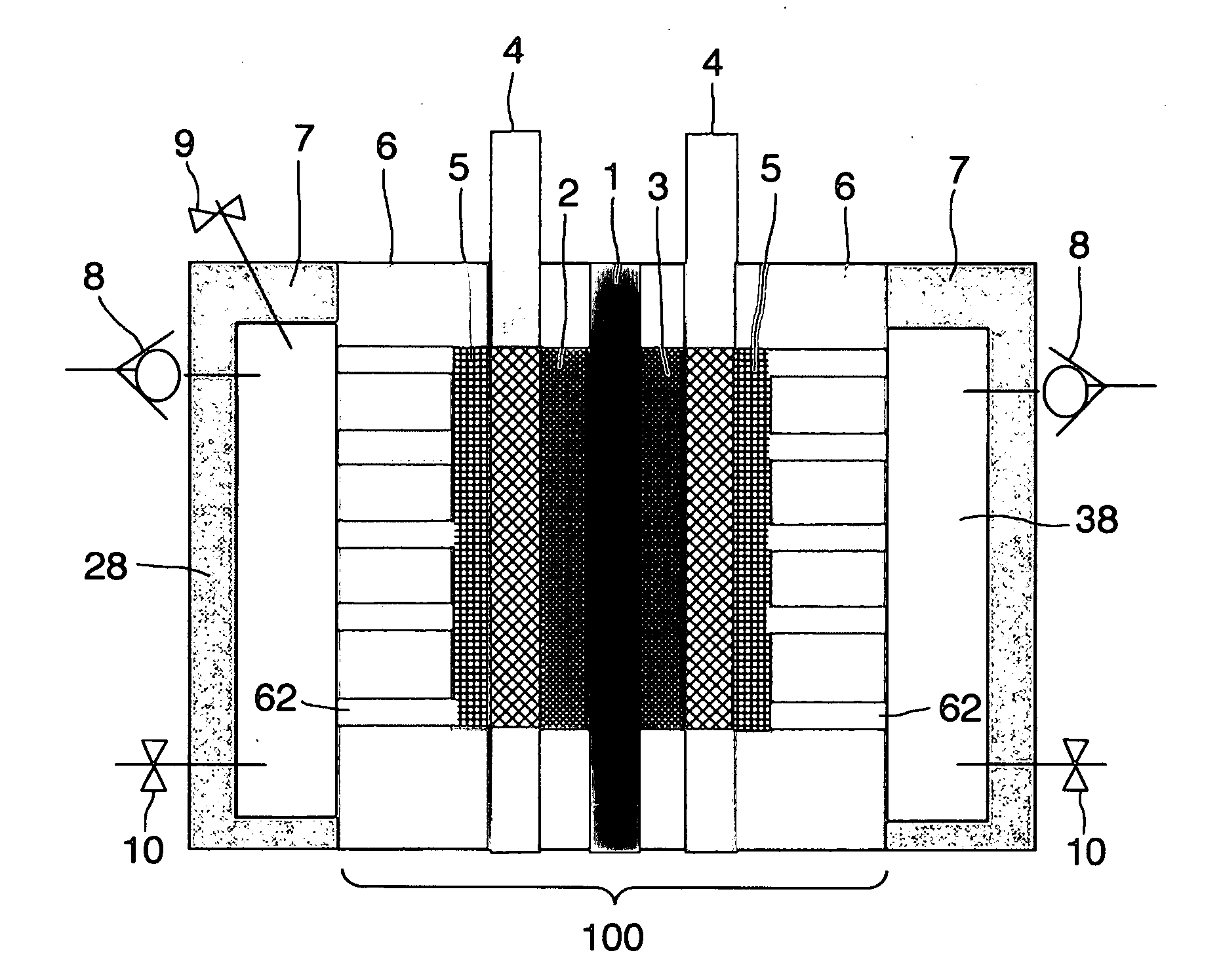

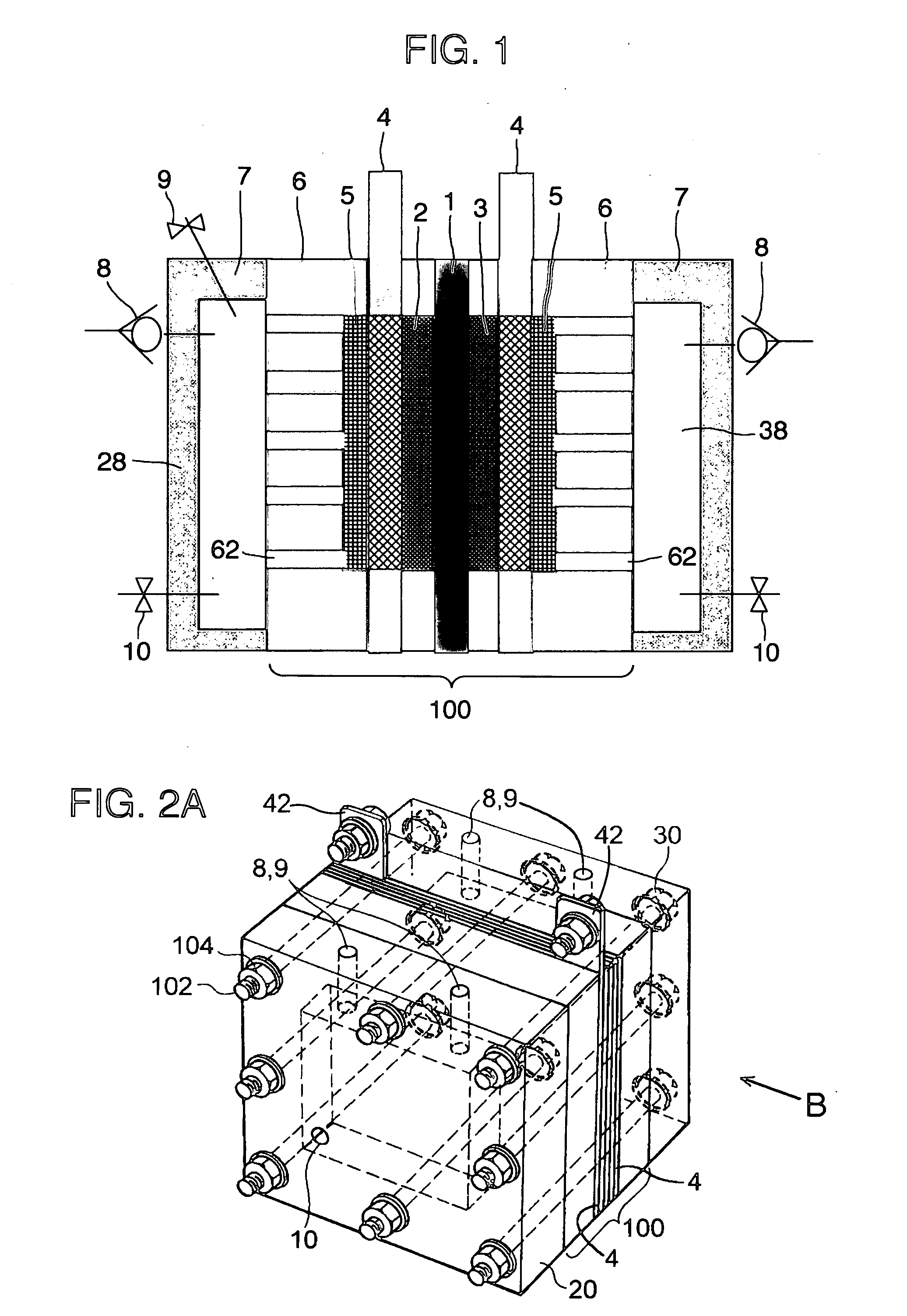

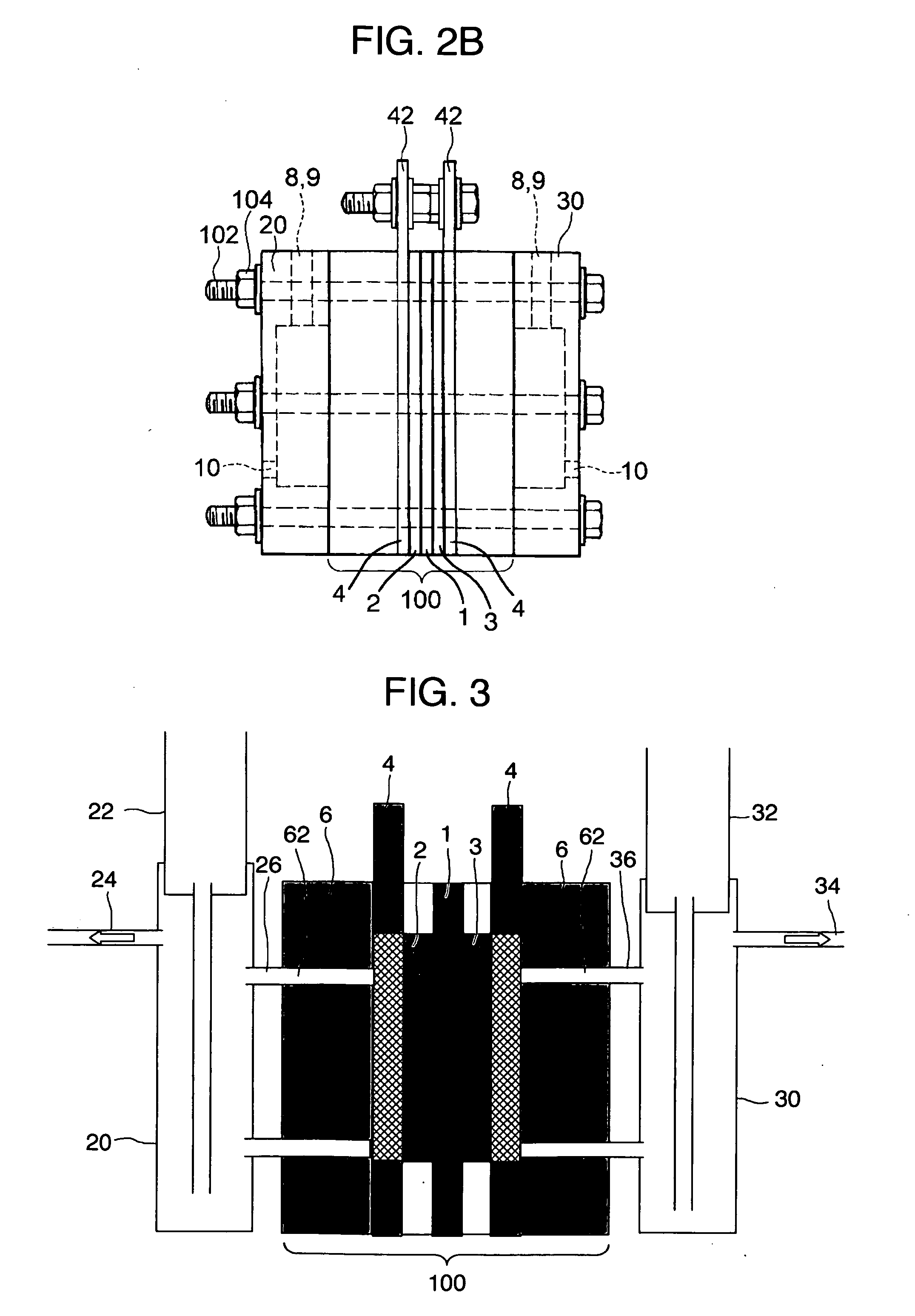

[0032] An embodiment of the present invention will now be described with reference to FIGS. 1, 2A and 2B.

[0033]FIG. 1 is a sectional view for explaining a solid polymer membrane-type water-electrolysis apparatus according to an embodiment of the present invention; FIGS. 2A and 2B show one example of the same solid polymer membrane-type water-electrolysis apparatus. FIG. 2A is a perspective view and FIG. 2B is a side view taken in a direction of an arrow B in FIG. 2A. This solid polymer membrane-type water-electrolysis apparatus includes an electrolytic cell 100 comprising a solid polymer electrolyte membrane 1 made of a material of perfluorocarbon sulfonic acid polymer or the like, an oxygen electrode 2 which is disposed on one side of the solid polymer electrolyte membrane 1 and which is formed by forming a coated layer of a mixture including a resin for a solid polymer electrolyte membrane on a porous sheet-shaped carbon material plated with iridium, a hydrogen electrode 3 which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com