System and method for efficient and expedient delivery of hot water

a technology of efficient and expedient delivery and hot water, applied in the mechanical and electrical arts field, can solve the problems of not only wasting water in conventional systems, but also remote hot water outlet, and waste of water flowing down the drain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] While specific embodiments are discussed below, it should be understood that this is done for illustration purposes only and that other components and configurations can be used in accordance with the systems and methods described herein without departing from the spirit of the invention.

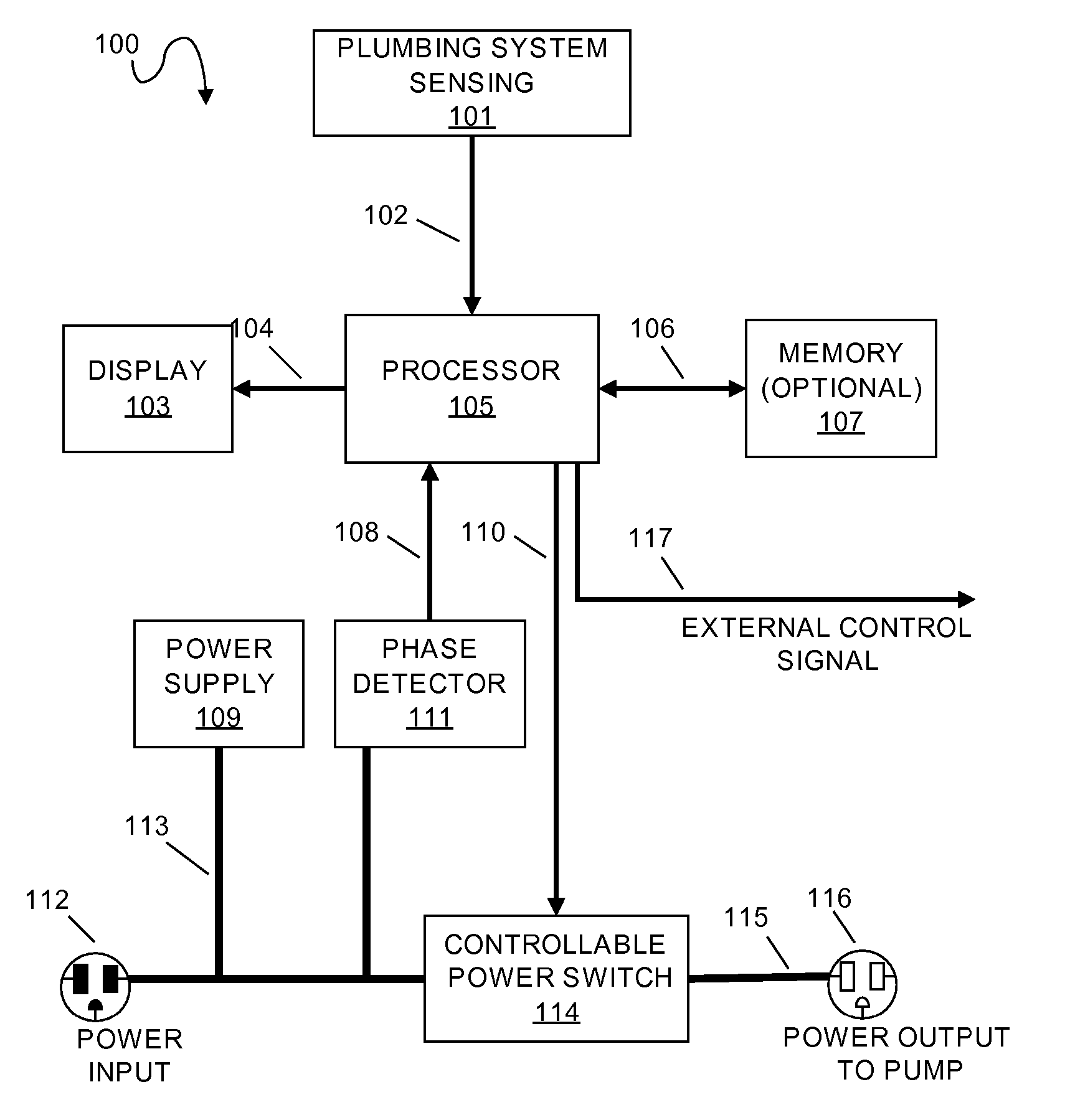

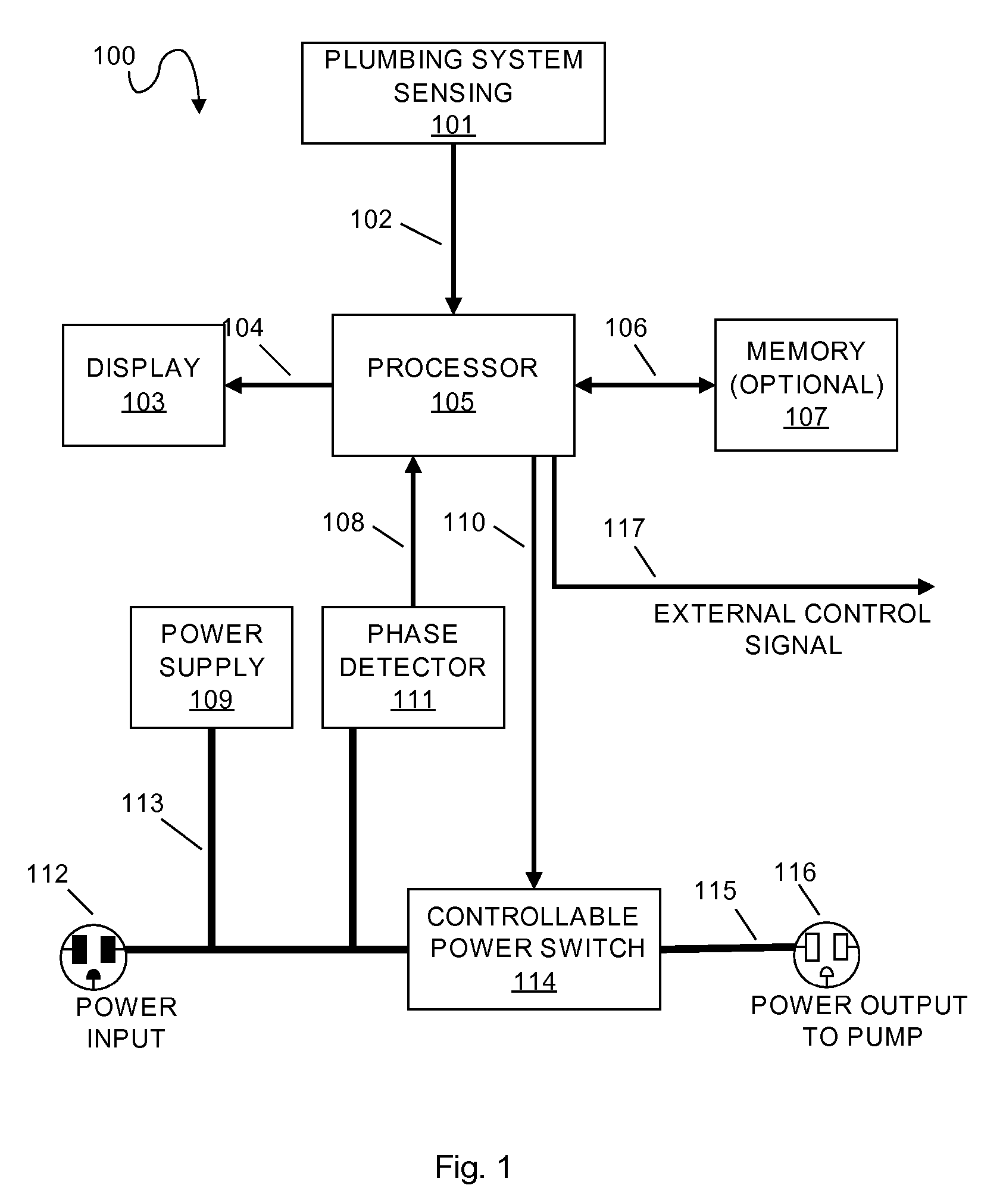

[0045]FIG. 1 shows a block diagram of an embodiment of a system 100 according to the present invention. Plumbing system sensing 101 comprises one or more sensors measuring or detecting properties of the plumbing system. These properties are of interest in controlling a hot water recirculation pump. These properties can include, for example, temperature, pressure, flow, or vibration at various points in the household or building plumbing system. In some embodiments one property of interest is derived from measuring another physical phenomenon, for example temperature or vibration can indicate flow. A variety of sensors can be used in various embodiments, all according to the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com