Awning bead and staple system

a technology of awnings and staples, which is applied in the direction of sunshades, building types, constructions, etc., can solve the problems of uneven appearance and material differences, and achieve the effect of improving the retention of fabric covering materials and facilitating the application of retention staples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

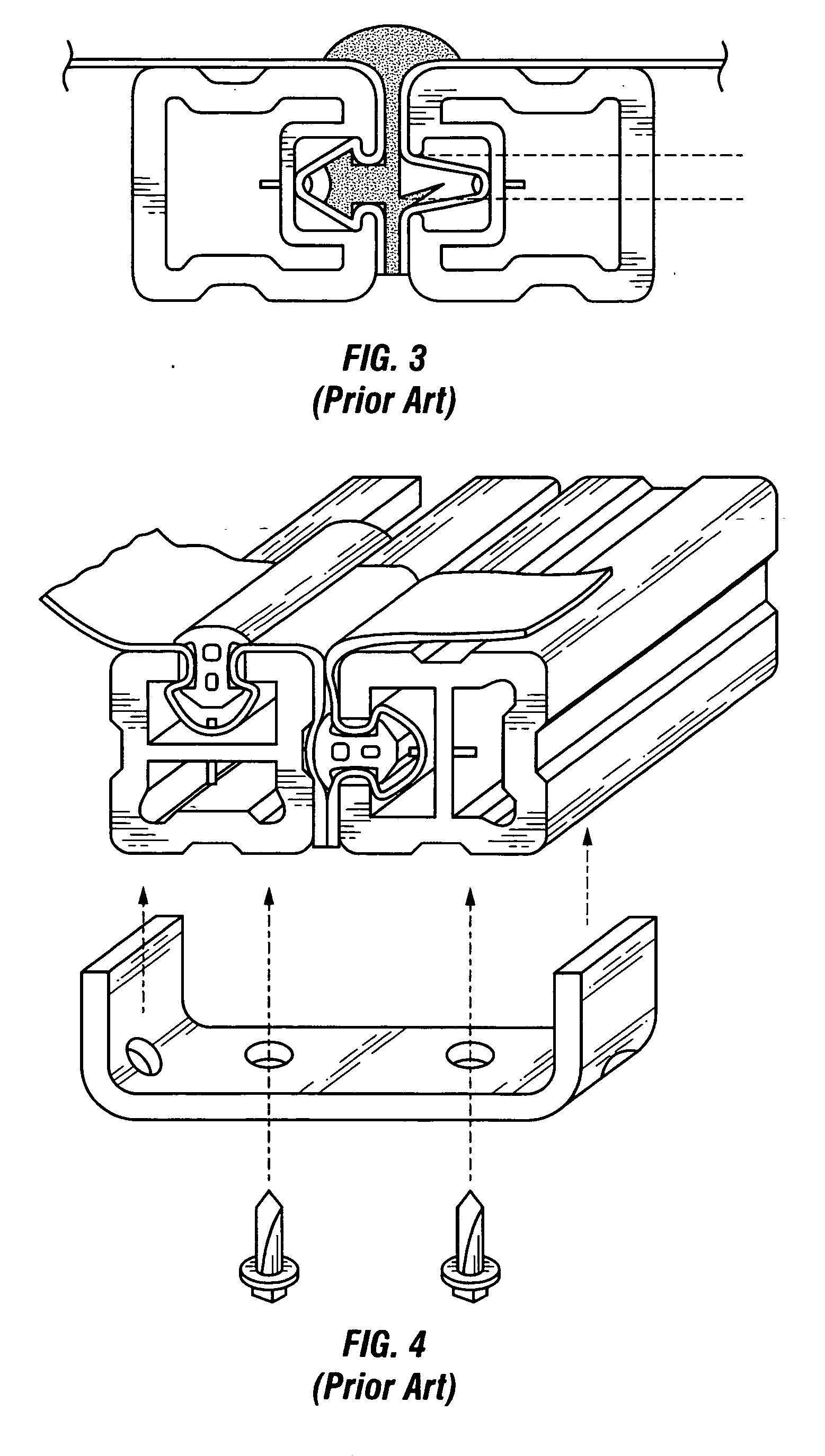

[0051] Turning now to the drawings in which like reference numbers represent like parts throughout the several views of the drawings, FIG. 8 illustrates a perspective view of one embodiment of the present invention. FIG. 8 details one embodiment of the awning bead and staple system 800 in which only one sheet of fabric covering material 816 is attached using the novel bead 802 and channel 808 disclosed herein. In a typical awning installation, the framing members 810 are measured and bent to an arcuate shape prior to installation. Once bent, the chosen fabric covering material 816 is stretched across the framing members 810 and fixedly attached to the inner surface of the channel 808 using an attachment means such as nails, screws, tacks, glue, heat tacking (melting of the covering material to the inner channel surface), or staples 814. The longitudinal groove 812 on the inner surface of the channel 808 serves as a guide for trimming excess fabric covering material 816 from the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com