Vacuum pressure controller

a vacuum pump and controller technology, applied in the direction of pump control, vacuum distillation separation, separation process, etc., can solve the problems of increasing the life of the pump and the temperature of the pump, and achieve the effect of preventing condensation in the vacuum pump, prolonging the maintenance interval, and prolonging the pump li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

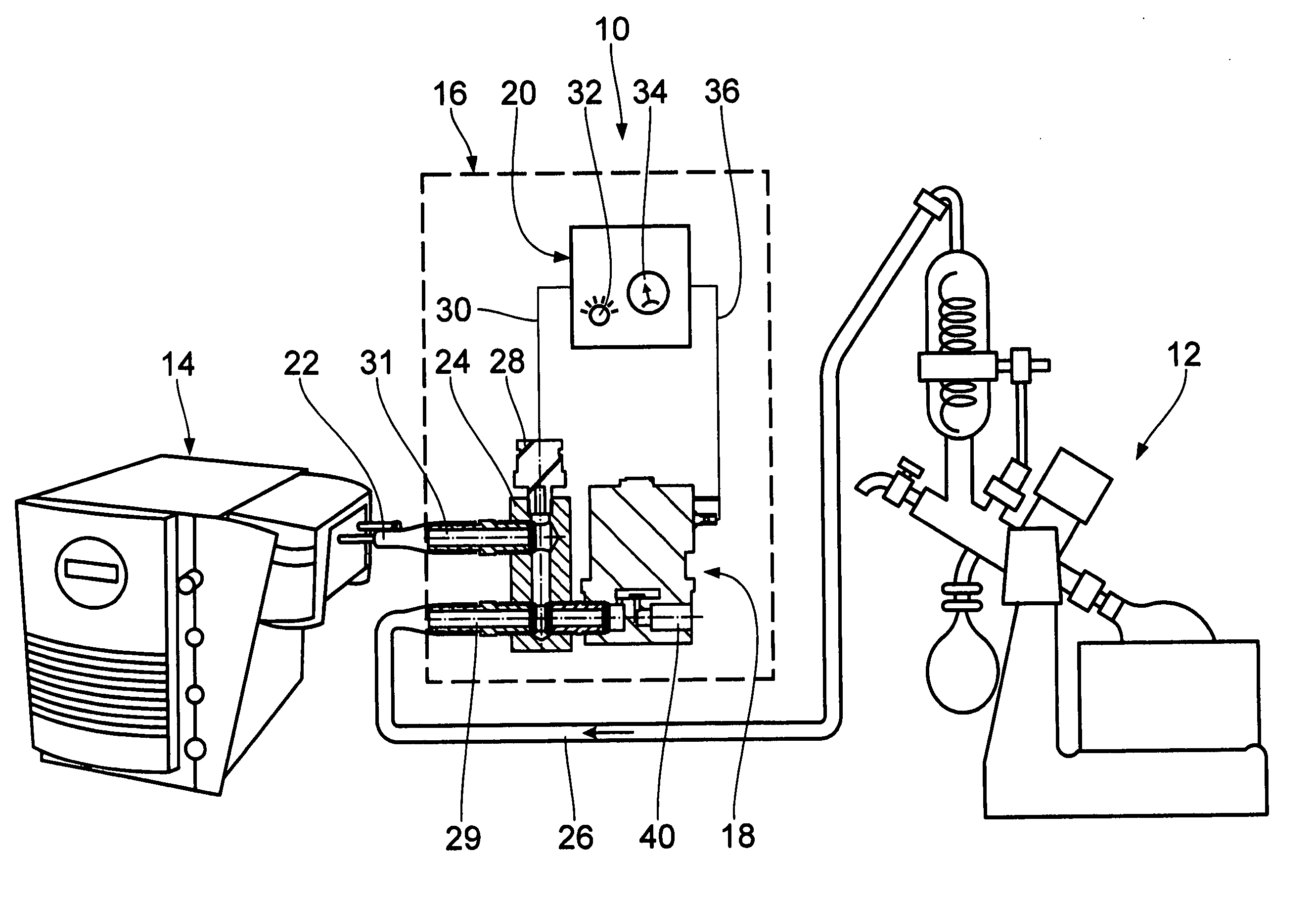

[0014] Referring to FIG. 1, the system 10 includes a rotary separator distillation apparatus 12, a vacuum pump 14 and a vacuum pressure controller 16 of the invention. The vacuum pressure controller 16 includes an air bleed valve 18 and a control unit 20. A first vacuum pressure line 22 connects the pump 14 to a manifold 24 of the unit 16 and a second vacuum pressure line 26 connects the manifold 24 to the rotary evaporator 12. A pressure transducer 28 is in communication with the manifold 24 to provide an electrical signal indicative of the vacuum pressure within manifold 24, which signal is input to control unit 20 by line 30. Control unit 20 includes dial 32 and pressure gauge 34 for a user to dial-in the level of vacuum that the user desires the system to produce. Line 36 connects the output of control unit 20 to the control input of valve 18 and control unit 20 controls valve 18, which may be a proportional valve or an on-off valve. Control unit 20 is similar to control units w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com