Controller for brushless motor

a brushless motor and control board technology, applied in the direction of dynamo-electric converter control, ac motor direction control, dynamo-electric gear control, etc., can solve the problems of conspicuous noise and limited calculation period of current voltage applied to the coil, so as to reduce noise at the update frequency, reduce the effect of calculation load and reduce the nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

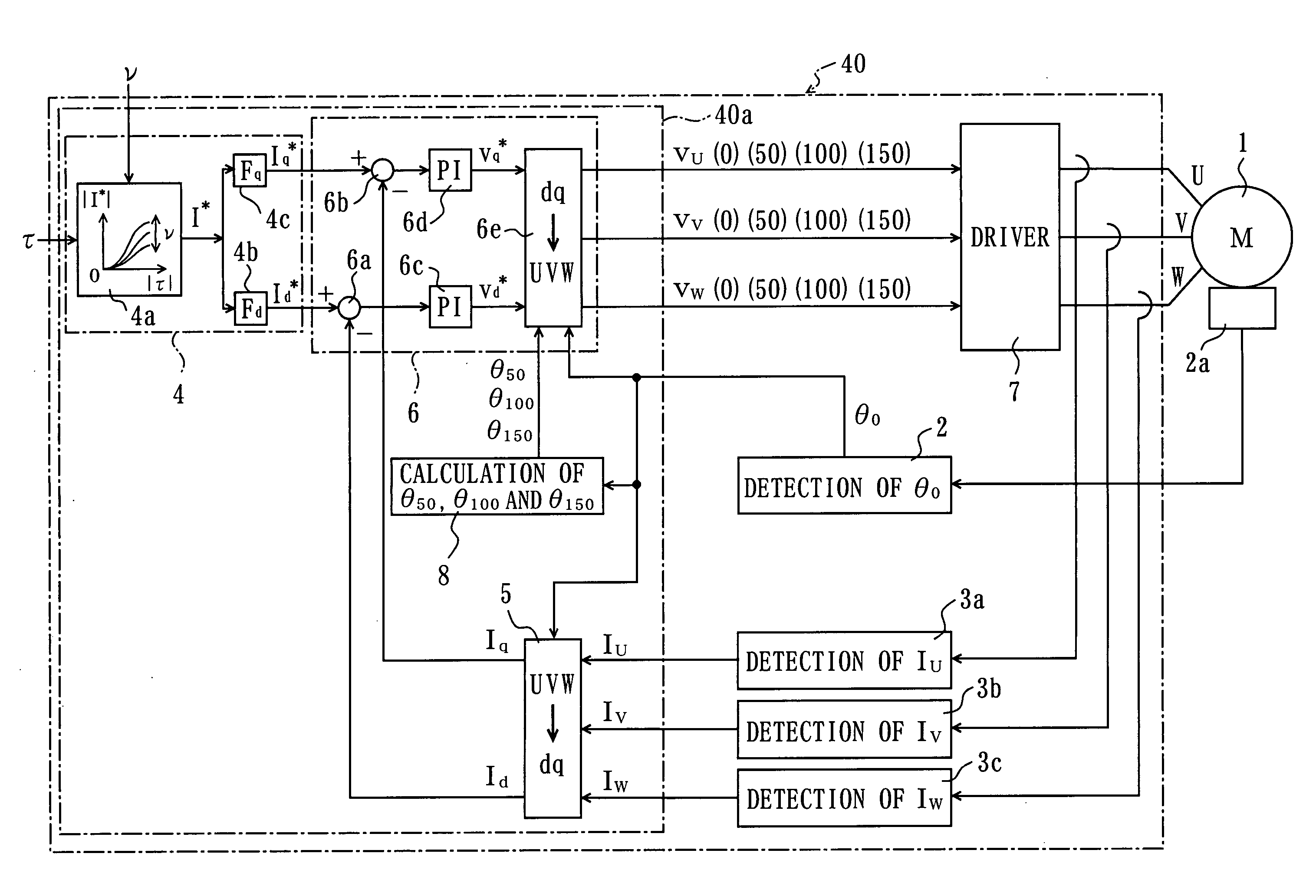

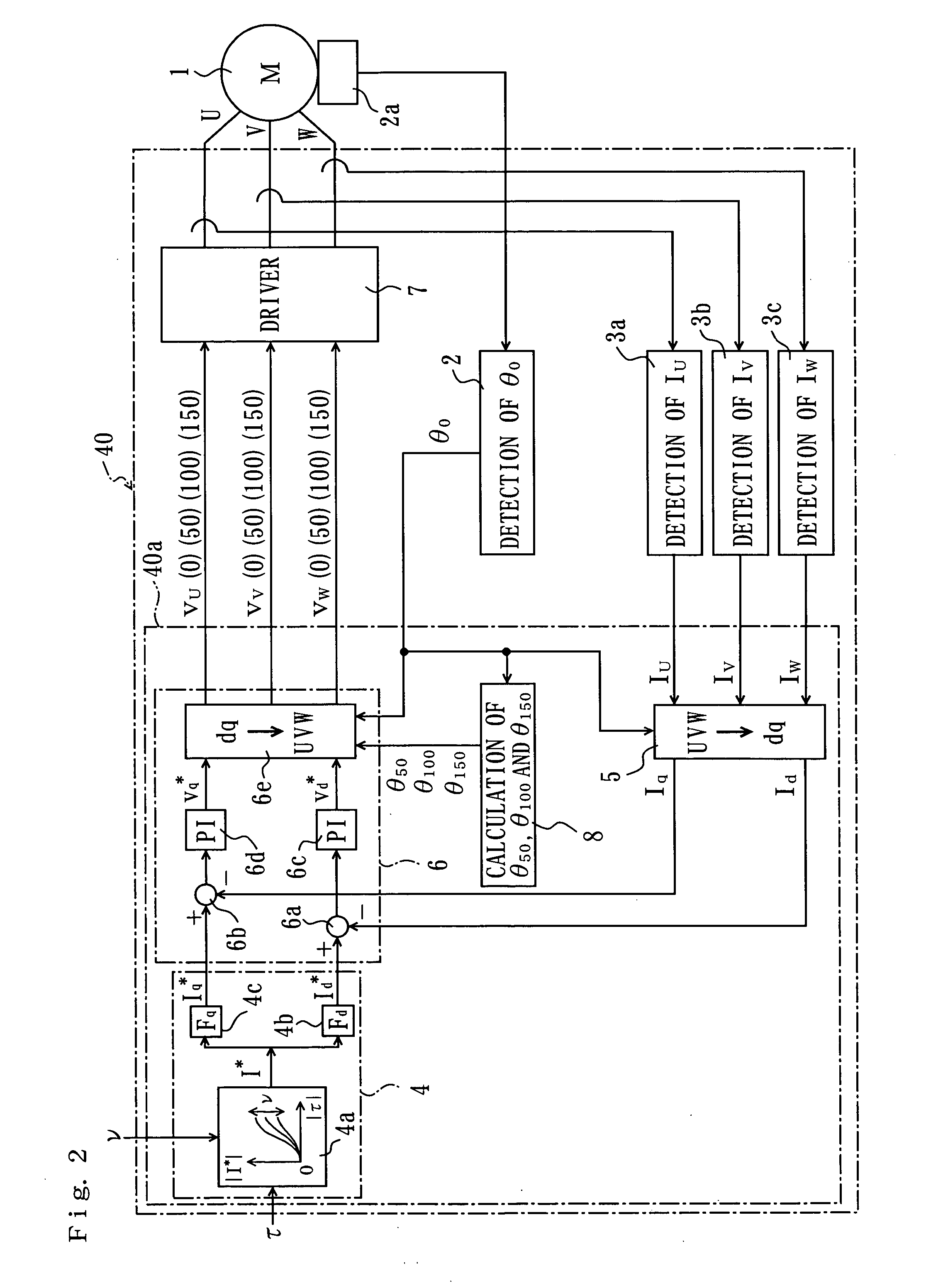

[0030] A controller for a brushless motor constituting the present invention is described with reference to FIGS. 1 through 8. In the present embodiment, parts that are the same as in the conventional example are labeled with the same symbols.

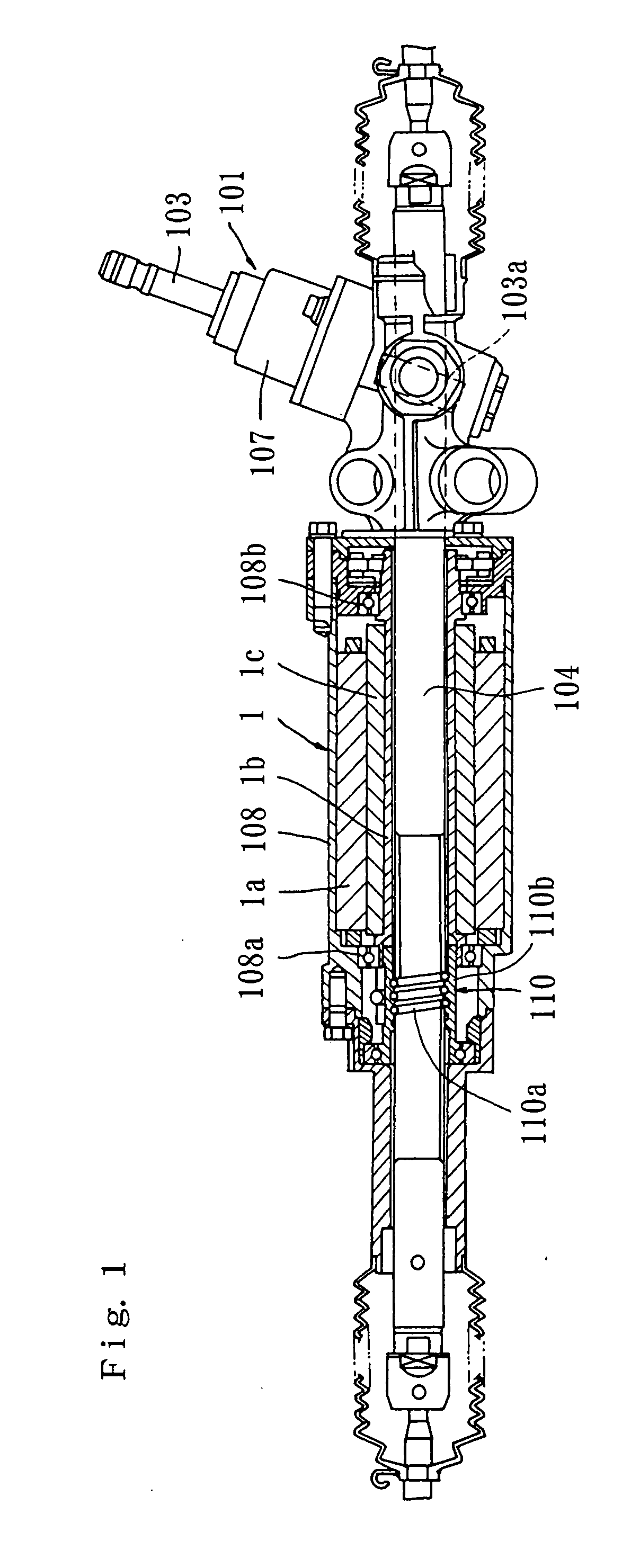

[0031] The rack and pinion type electrical power steering apparatus 101 for a vehicle shown in FIG. 1 comprises a steering shaft 103 that is caused to rotate by steering operation, a pinion 103a that is disposed on the steering shaft 103, and a rack 104 that engages with the pinion 103a. Both ends of the rack 104 are connected to vehicle wheels (not shown in the figures) used for steering. When the pinion 103a is caused to rotate by steering operation, the rack 104 moves in the longitudinal direction along the lateral direction of the vehicle, and the steering angle varies as a result of this movement of the rack 104. A torque sensor 107 which detects the steering torque, a three-phase brushless motor 1 which is driven in accordance with the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com