Color harmonization coatings for articles of manufacture comprising different substrate materials

a technology of color harmonization and substrate materials, applied in the field of color harmonization, can solve the problems of difficult to provide a uniform visual appearance of the article when the components are assembled, relatively complex and costly manufacturing processes, and not maintaining the same appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

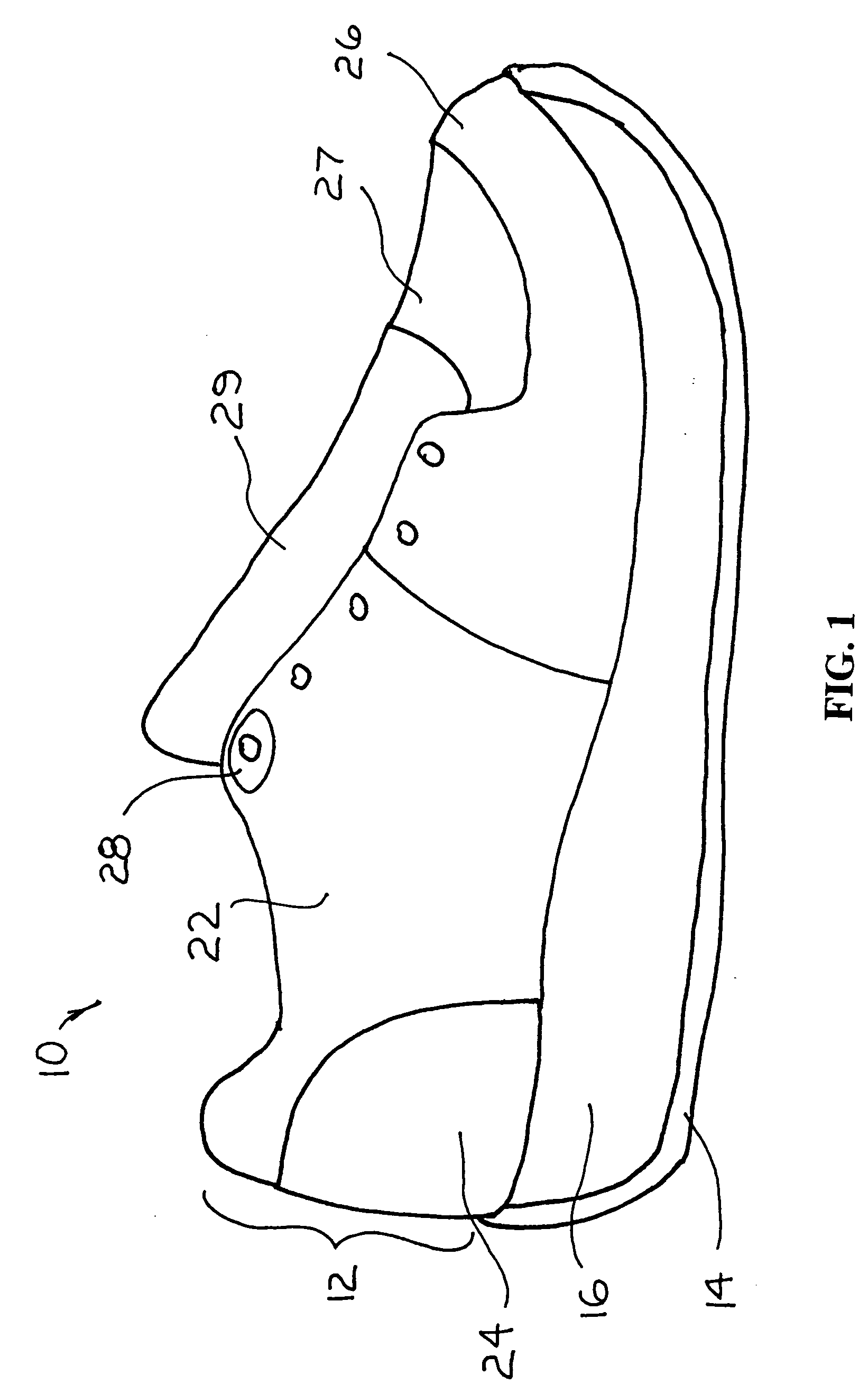

Image

Examples

example 1

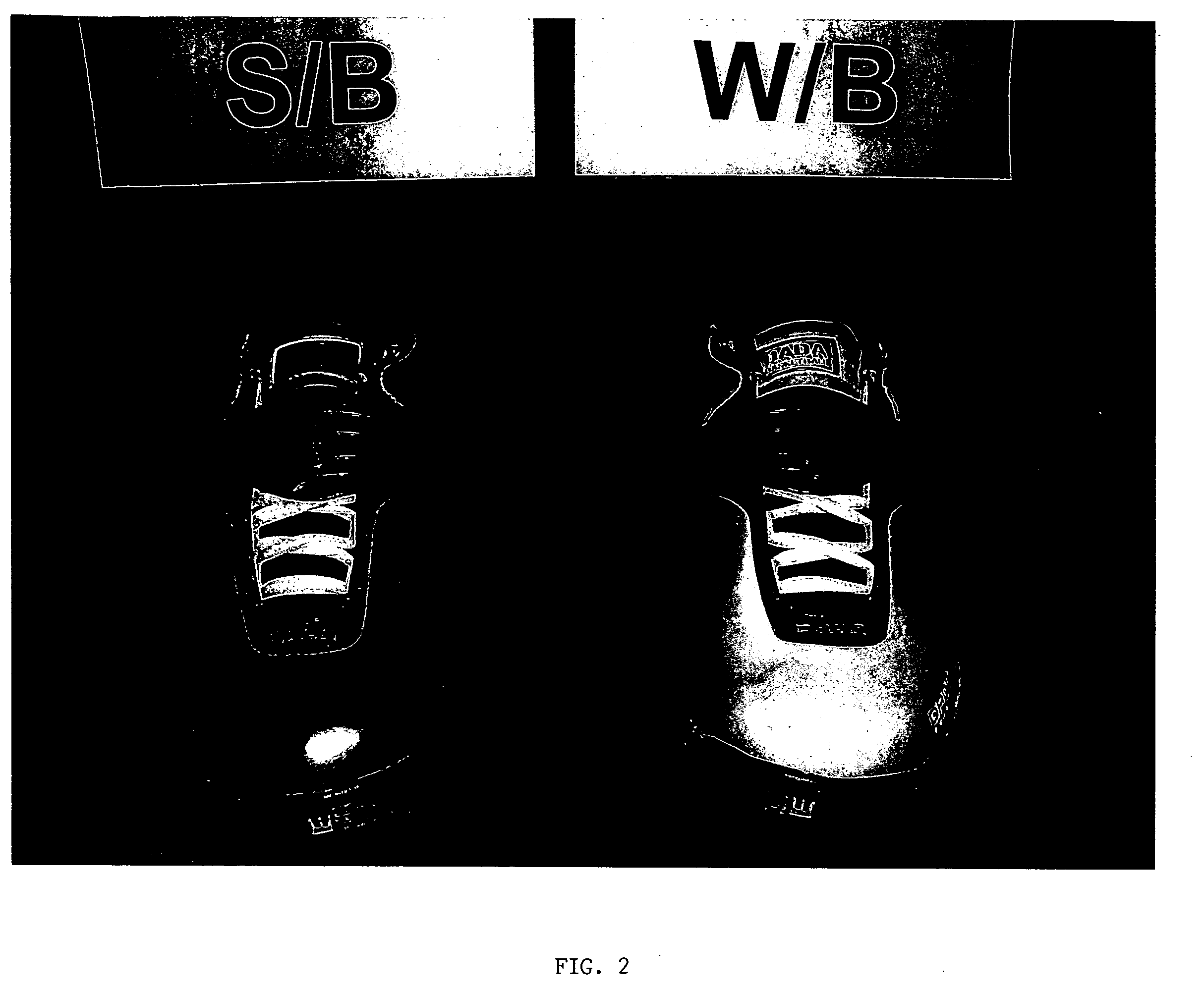

[0058] An aqueous color harmonization coating composition was made and applied to athletic shoe components comprising different materials as follows. A polyurethane dispersion was made by charging a reaction vessel equipped with stirrer, thermocouple, condenser and nitrogen inlet with 1447.3 g polytetramethylene ether glycol having a molecular weight of about 1,000 sold under the designation TERATHANE 1000, 145.4 g dimethylolpropionic acid and heated to 60° C. 965.3 g isophorone diisocyanate was added over 13 minutes followed by 637.5 g methyl ethyl ketone and 4.34 g dibutyltin dilaurate. The reaction exothermed to 72° C. The reaction temperature was raised to 80° C. and the contents were stirred until the isocyanate equivalent weight was 923.5. Then 114.0 g dimethylolpropionic acid was added to the reaction flask. The contents were stirred until the isocyanate equivalent weight was 1430.2.

[0059] 1512.2 g of the above prepolymer at a temperature of 75° C. was then added over a 16 m...

example 2

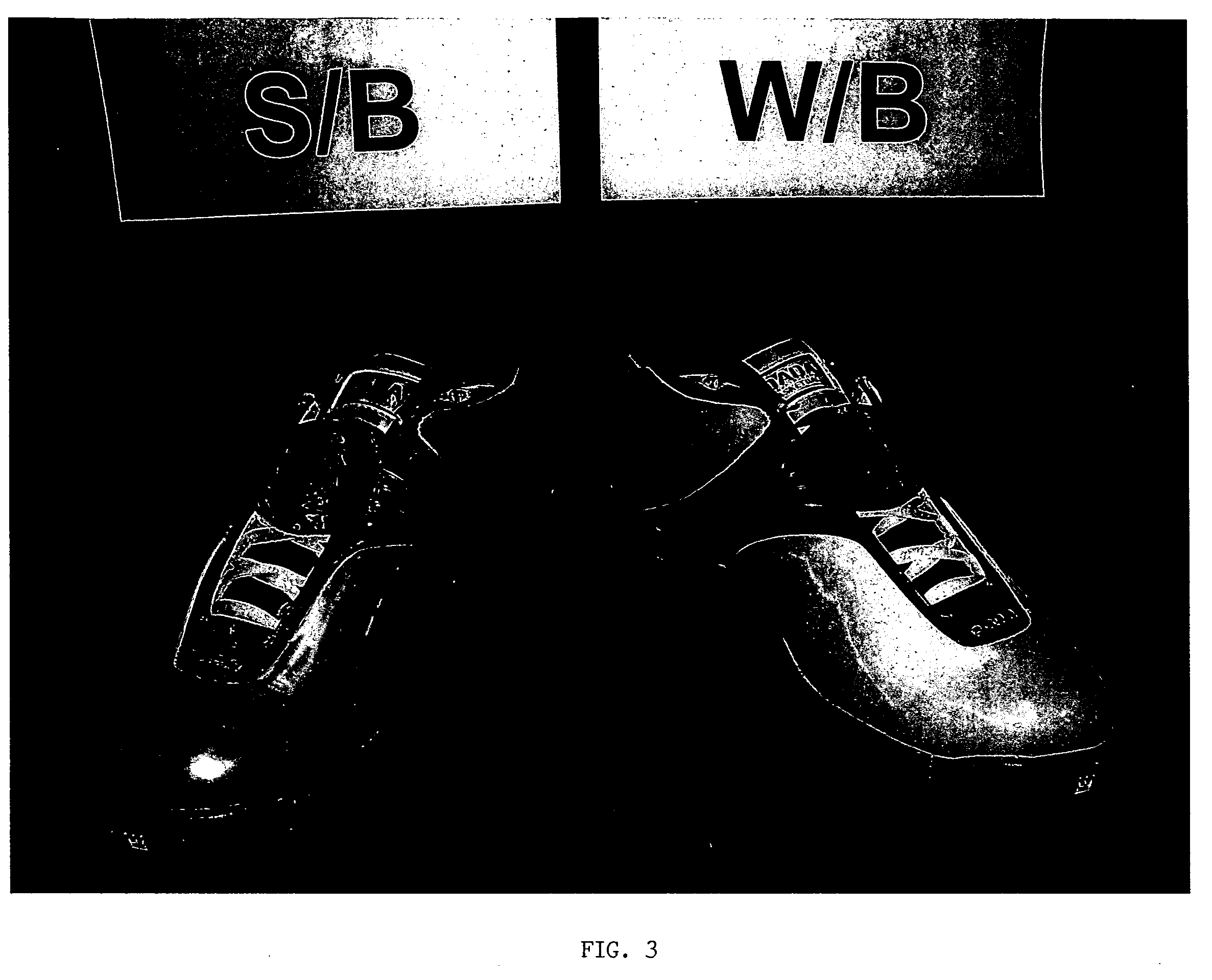

[0065] A solvent-based color harmonization coating was made and applied to athletic shoe substrates as follows. A two-component pigmented polyurethane coating composition was prepared. As shown in Table 2, Component A is comprised of two polyester resins and other ingredients.

TABLE 2Solvent-Based 2K Polyurethane FormulationsRed CoatClear CoatIngredientWt. %Wt. %Component APolyester Polyol (a)17.414.7 Polyester Polyol (b)21.02.0Acrylic Resin Solution33.6—Pigmentation4.6—Acrylic Polyol Solution4—2.1Cellulose acetate butyrate Resin51.8—Non functional acrylic resins—8.7UV stablizers / absorbers6 .36 .92Tin Catalyst7 .03 .02BENTONE / Silicon Dioxide additives8 .03—Polysiloxane additive9 .03 .05Solvent1037.0638.66Coating Solvent Reducer 30.211 22.112Component BHDI Isocyanate138.49.4Solvent Blend 5.614 1.515NCO / OH3.42.2

% based on total weight (g) of component A and B combined

1DESMOPHEN 1652A - functional polyester commercially available from Bayer Corporation

2DESMOPHEN 670A-80 - function...

example 3

[0078] A solvent-based color harmonization coating was made and applied to athletic shoe substrates as follows. A two-component pigmented polyurethane coating composition was prepared. As shown in Table 5, Component A is comprised of two polyester resins and other ingredients.

TABLE 5Solvent-Based 2K Polyurethane FormulationIngredientRed CoatComponent APolyester Polyol (a)110.4Polyester Polyol (b)21.4Acrylic Resin Solution33.6Pigmentation3.5Acrylic Polyol Solution4—Cellulose acetate butyrate Resin52.1Non functional acrylic resins—UV stablizers / absorbers60.5Tin Catalyst70.03BENTONE / Silicon Dioxide additives80.10Polysiloxane additive90.05Solvent1035.48DISPERBYK 167110.01ANTI-TERRA-U100110.02Coating Solvent Reducer1228.55Component BHDI Isocyanate138.6Solvent Blend145.7NCO / OH3.0

% based on total weight (g) of component A and B combined

1DESMOPHEN 1652A- functional polyester commercially available from Bayer Corporation

2DESMOPHEN 670A-80 - functional polyester commercially available fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com