Adjustable holder for cleaning implement

a technology of cleaning implements and adjustable brackets, which is applied in the direction of cleaning machines, manufacturing tools, carpet cleaners, etc., can solve the problems of material breakage and difficulty in adjusting the position of the holder, and achieve the effect of low production and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

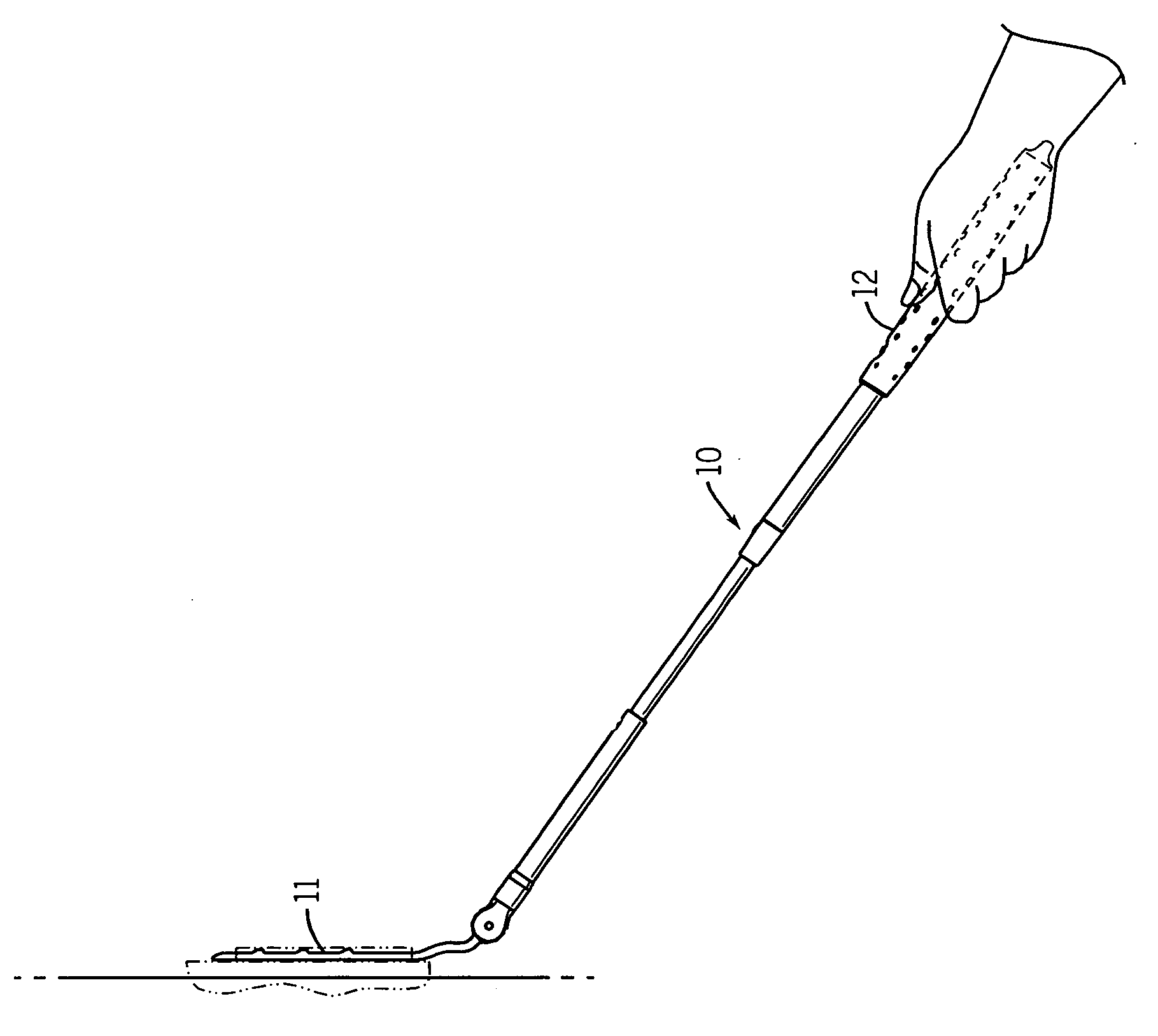

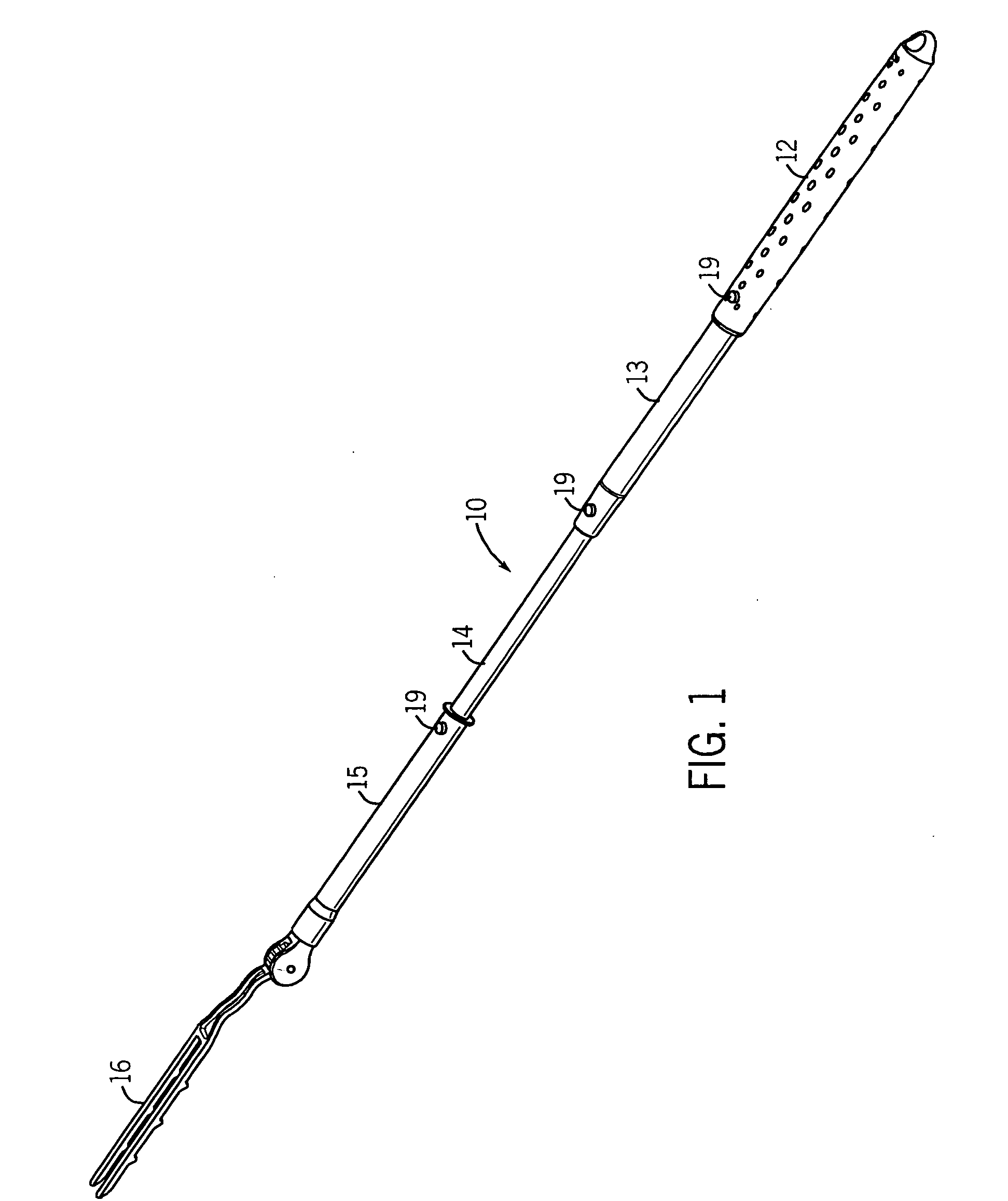

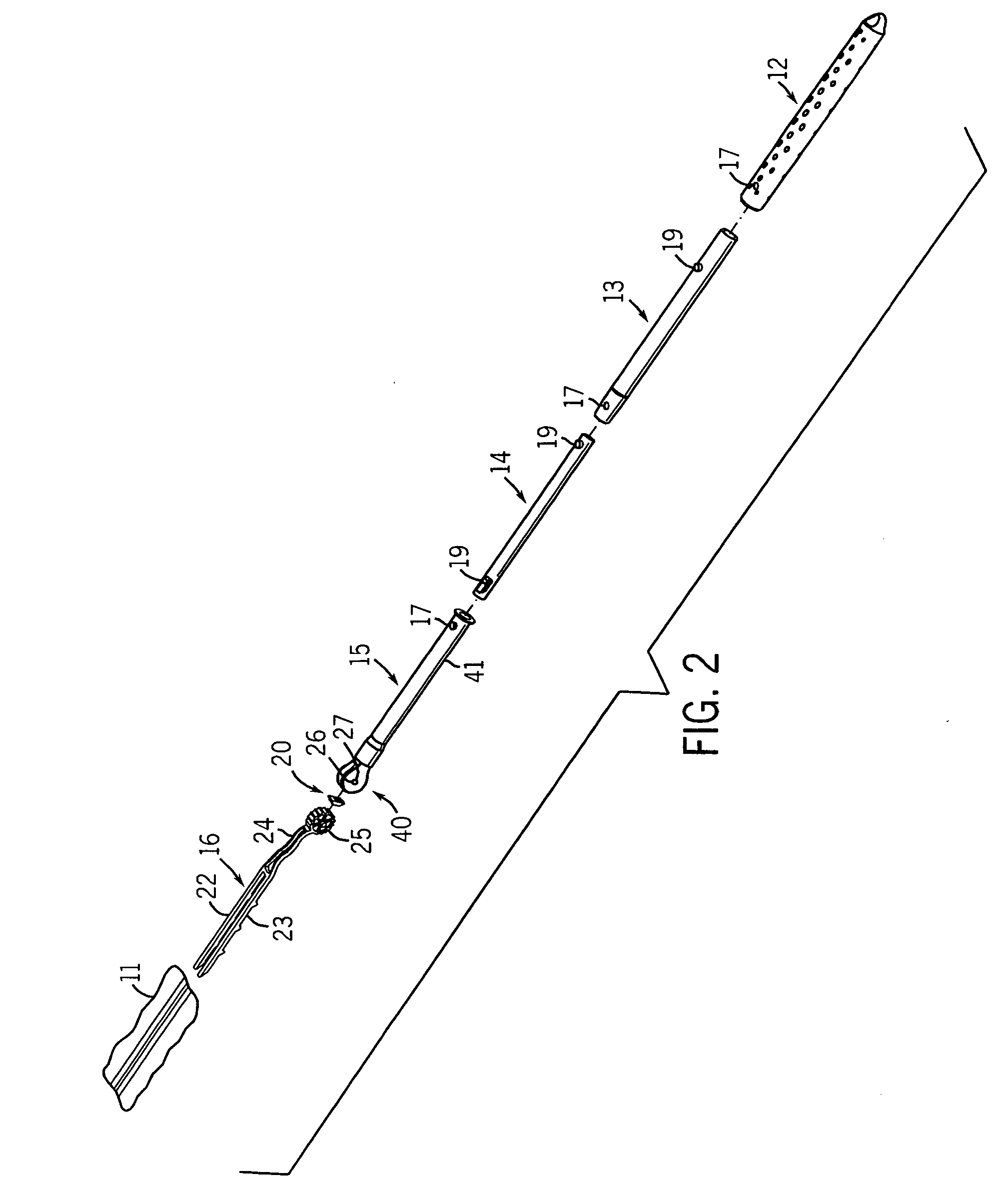

[0032] As best seen in FIGS. 1 and 2, there is shown a holder 10 designed to be used with a cleaning implement / replaceable dusting sleeve / cleaning mitt 11. The holder has a grip 12, telescoping handle extension pieces 13 and 14, shank 15 and support head 16. There is also a resilient catch 20.

[0033] In this preferred form various radially extending bumps 19 are formed on some of these parts which fit into corresponding catch holes 17 on adjacent parts. While not shown in detail, these bumps 19 are preferred to be positioned on flexible tabs which can deflect radially inwardly as the tubular parts are assembled to one another, and then flex radially outwardly into the holes 17 to temporarily fix the tubular parts in the FIG. 1 position.

[0034] One can then press the bump 19 of extension part 13 radially inward to permit extension part 13 to telescope into a hollow of handle grip 12. Similarly, the bump 19 on the rear end of extension part 14 can be pressed radially inward to permit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com