Water cooling system for computer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 100

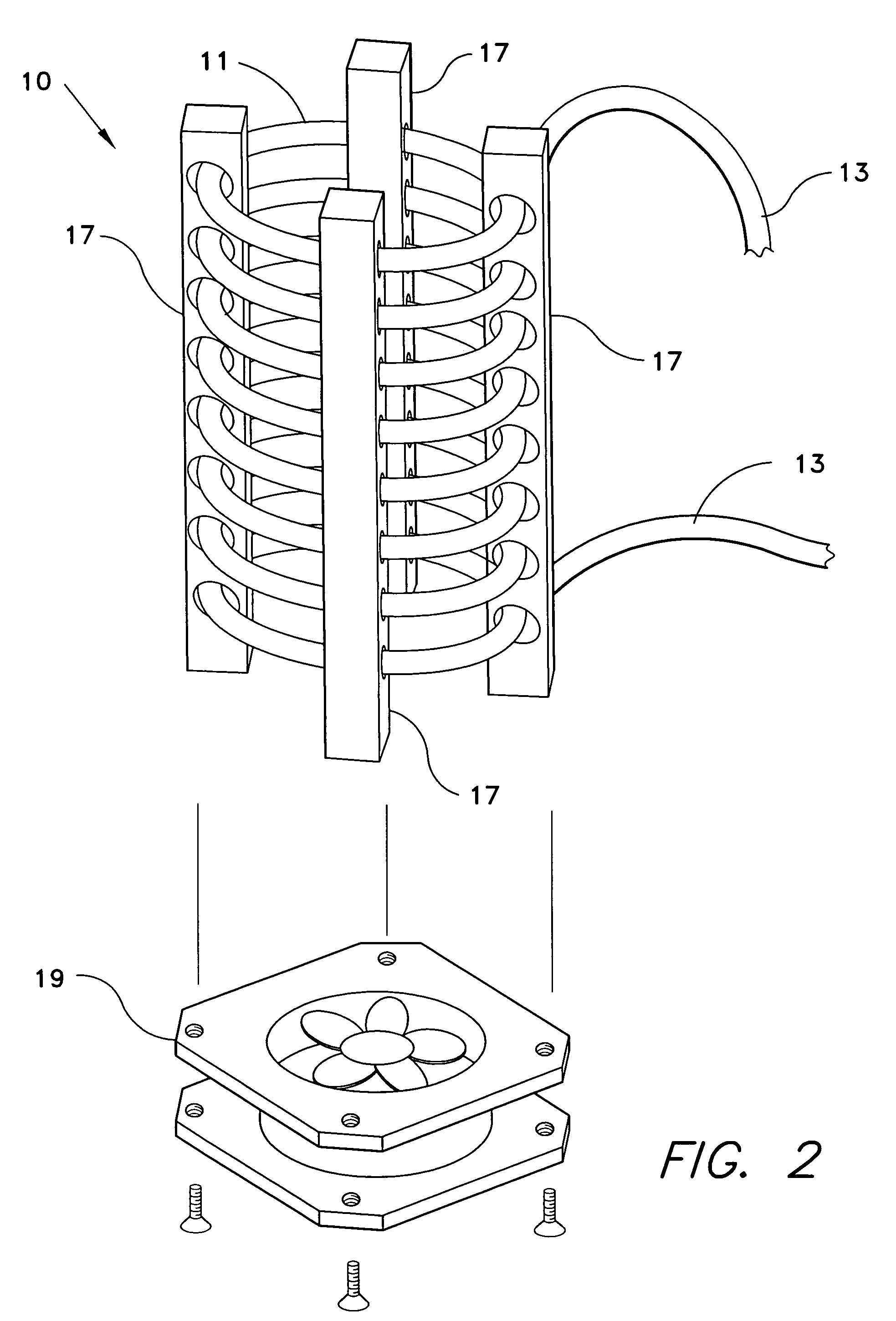

[0028] Turning now to FIGS. 4 and 5, an embodiment 100 of a water-block heat exchanger 20 for a computer system's CPU is shown. The CPU water-block 100 is formed from a single piece, solid block 110 of a metal such as aluminum or copper, or another material having a suitable heat-conducting property, the block 110 being generally square and having dimensions compatible with a computer CPU such as the Pentium© processor made by Intel©. A water channel 120 is formed within the block 110 by drilling a several interconnecting holes into the block 110. The block 110 is a square block having four sides 111, 111B, 111C and 111D, a top surface 113 and a bottom surface 115. Corners 117 of the block are beveled to assist in aligning the mounting bracket 25 with the block 110.

[0029] The water channel 120 comprises a first hole 121 drilled into a side 111A of the block 110, and extending substantially, but not completely, through the block 110. The first hole 121 lies adjacent and parallel to t...

embodiment 200

[0031] Turning now to FIGS. 7 and 8, an embodiment 200 of a water-block heat exchanger 20 for a computer system's VGA chip is shown. The VGA water-block 200 is formed from a solid block 210 of a metal such as aluminum or copper, or another material having a suitable heat-conducting property, the block 210 being generally square and having dimensions compatible with a typical computer system VGA chip. A water channel 220 is formed within the VGA water-block 200 by drilling a several interconnecting holes into the block 210. The block 210 is a generally square block having four sides 211A, 211B, 211C and 211D, a top surface 213 and a bottom surface 215. Opposing corners of the block 210 are beveled to form opposing corner faces 217.

[0032] The water channel 220 comprises a first hole 221 drilled into one of the corner faces 217, and extending diagonally through the block 210, passing through the center of the block 210. The first hole 221 may extend entirely through the block, exiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com