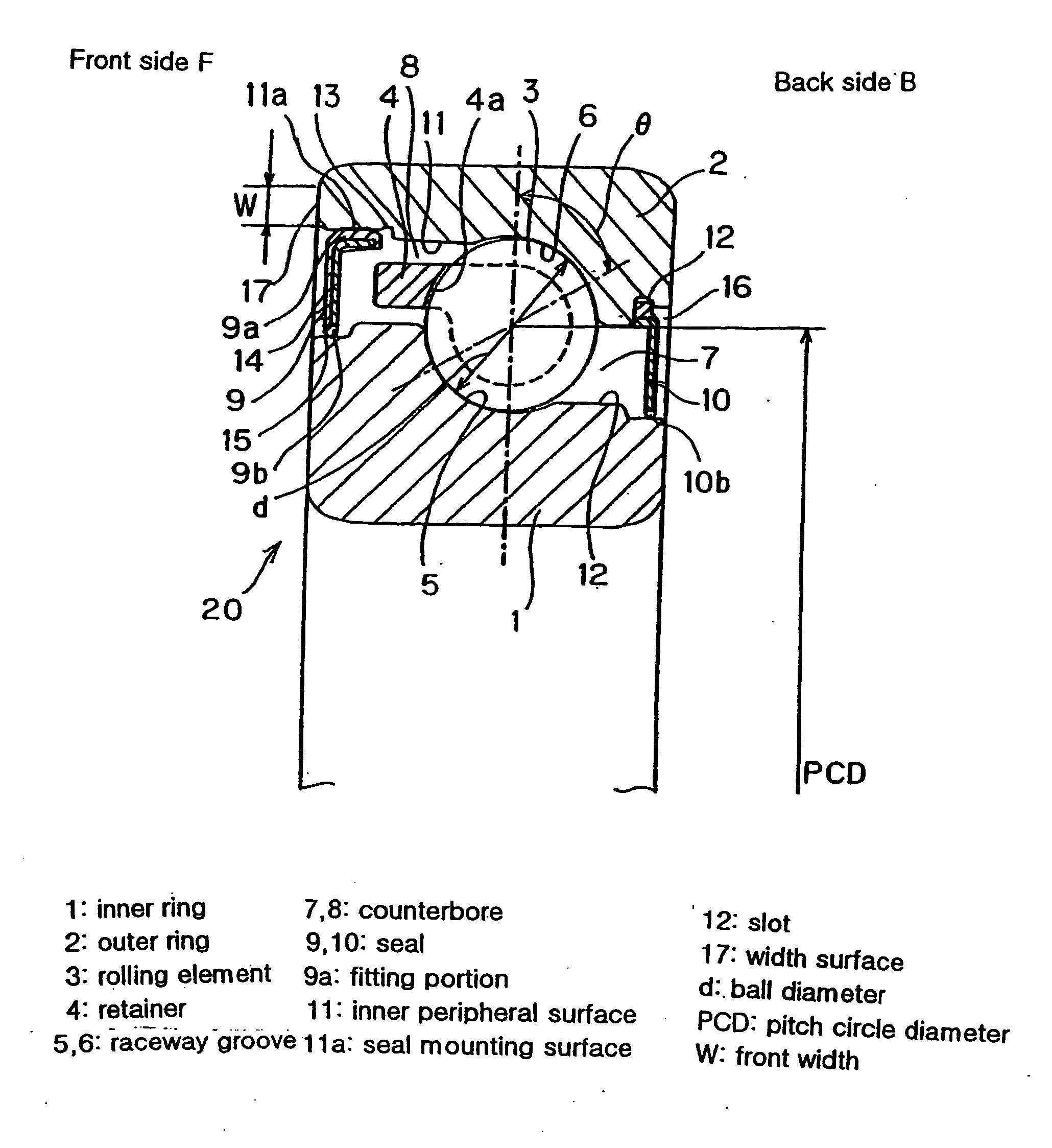

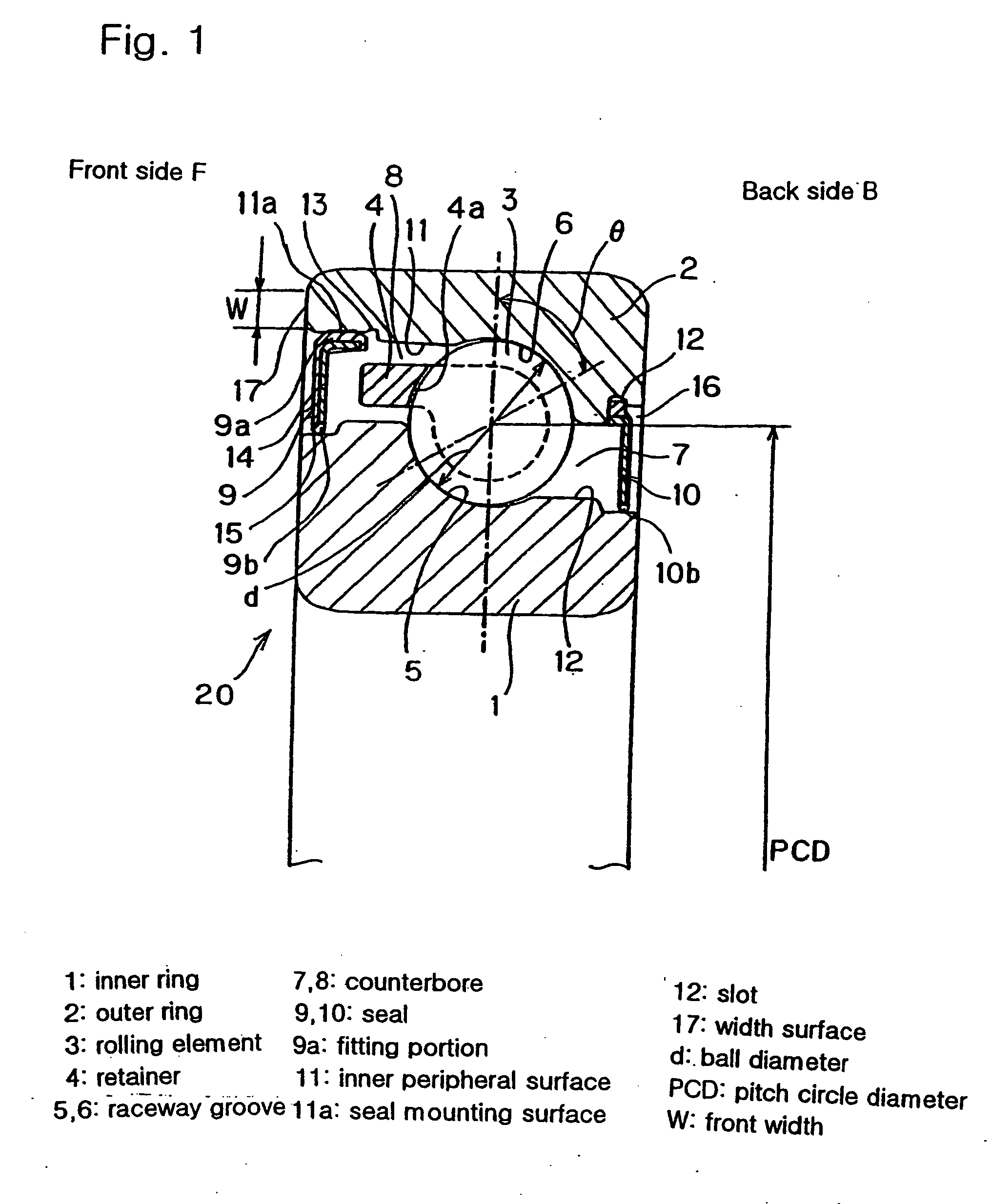

Angular ball bearing and rolling bearing

a technology of rolling bearings and bearings, which is applied in the direction of bearing cooling, thickeners, mechanical instruments, etc., can solve the problems of poor rotation accuracy, deterioration of bearing performance, and affecting the rotation accuracy of the bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Micro Pivoting Wear Test

[0093] The outer ring 90a and inner ring 90b that have been subjected to the abovesaid carbonitriding, and rolling elements 90C (made of SUJ2) were assembled to manufacture a bearing 91 (inner ring inner diameter×outer ring outer diameter×width=20 mm×40 mm×14 mm). At this time, 1 g of urea grease described in Table 1 was sealed (grease is not shown in FIG. 13). Using this bearing 91, Fafnir fretting corrosion test was conducted under ASTM D 4170. Specifically, as shown in FIG. 14, the outer ring 90a and the inner ring 90b were fixed to two bearing retaining portions 96, and a shaft 93 was passed to a bolt 92 in the order shown. And by adjusting the tightening of the bolt 92, a load was applied by a spring 94 (load=2.45 kN). With a chuck portion set in a tester, a pivoting portion 95 and a motor were coupled together by a crank rod, and the motor was rotated in the atmosphere at room temperature. With the pivoting angle set to 12 deg (critical pivoting angle:...

example 2

Microscopic Slide Wear Test

[0098] With rolling elements (made of SUJ2) placed on a plate subjected to the carbonitriding, and using the urea grease described in Table 1 as a grease, micro slide wear tests were conducted by the following method. As for the test conditions at this time, the load applied to the rolling elements was 98 N, amplitude of the rolling elements on the plate was 0.47 mm, the frequency was 30 Hz, the number of loadings was 8.6×105 cycles, and the test time was eight hours.

[0099] And at 5 or more points and in a direction perpendicular to the wear direction, measurement was made on a Talysurf surface profiler and the deepest value was used as the plate wear depth. Also, the wear amount (γ) of the rolling elements was calculated by measuring the wear diameter with a microscope and using the following formula. The results of plate wear depth are shown in FIG. 16, and the results of wear amount of the rolling elements are shown in FIG. 17.

ν=(πh2×(3r−h)) / 3

h=r−(4...

example 3

[0104] An inner ring 81 and an outer ring 83 made of SUJ2 were subjected to the carbonitriding and assembled with rolling elements made of SUJ2 to manufacture the angular ball bearing shown in FIG. 11. And as a grease, urea grease shown in Table 1 was sealed. A load of 6.9 kN (radial load) was applied to the bearing and it was rotated at 2000 rpm. The accumulated breakage probability 10% life at this time was measured. The results are shown in FIG. 18.

[0105] The “Accumulated breakage probability 10% life” refers to the substantially total number of revolutions or operating hours during which 90% (reliability 90%) of identical bearings in a group can be rotated without producing flaking due to rolling fatigue when they are individually rotated under the same conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com