Suspension ski boot

a ski boot and suspension technology, applied in the field of ski boots, to achieve the effect of enhancing comfort and flexibility, maximum lateral stiffness, and comfort and performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] * Numerals in parentheses refer to specific parts of the invention listed in the various drawings.

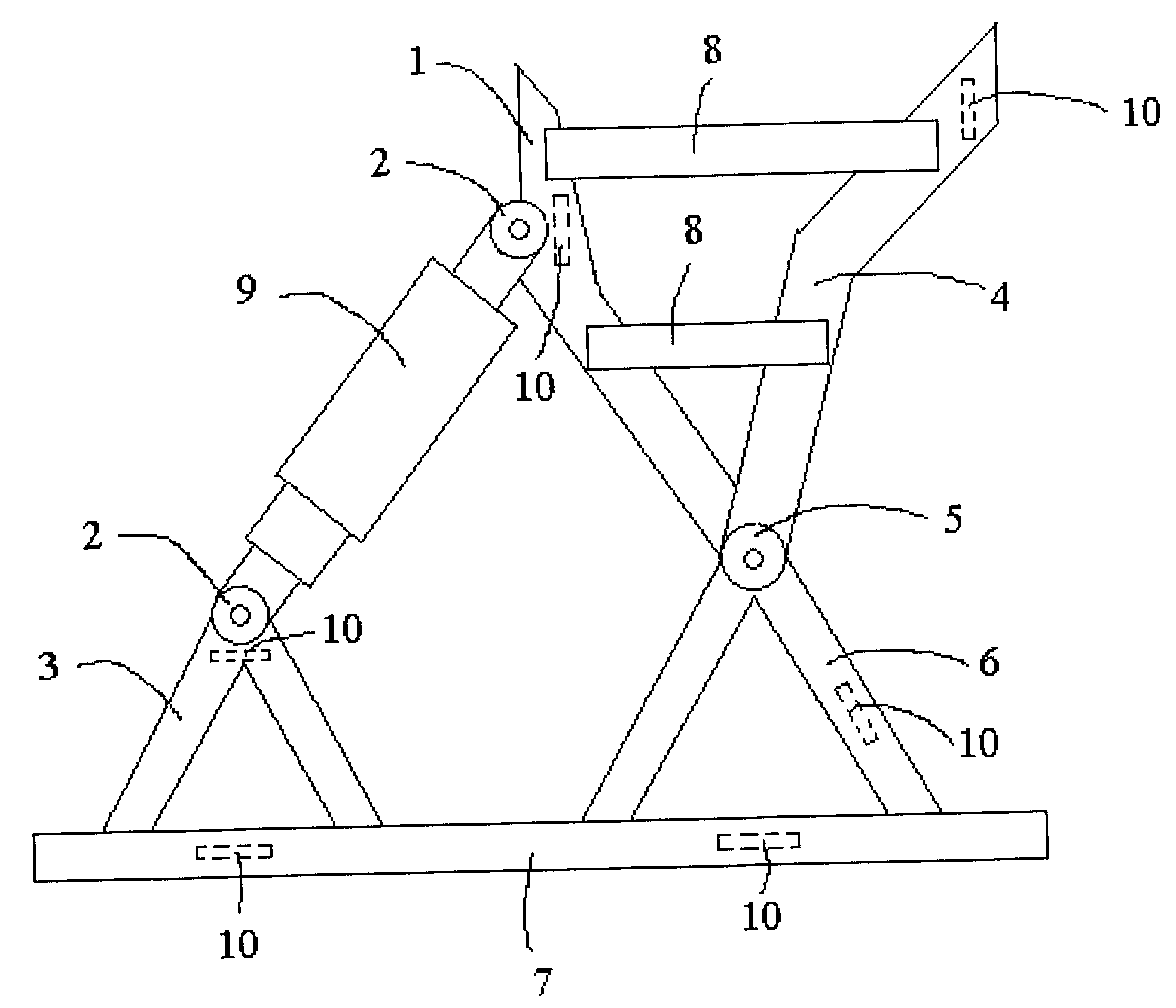

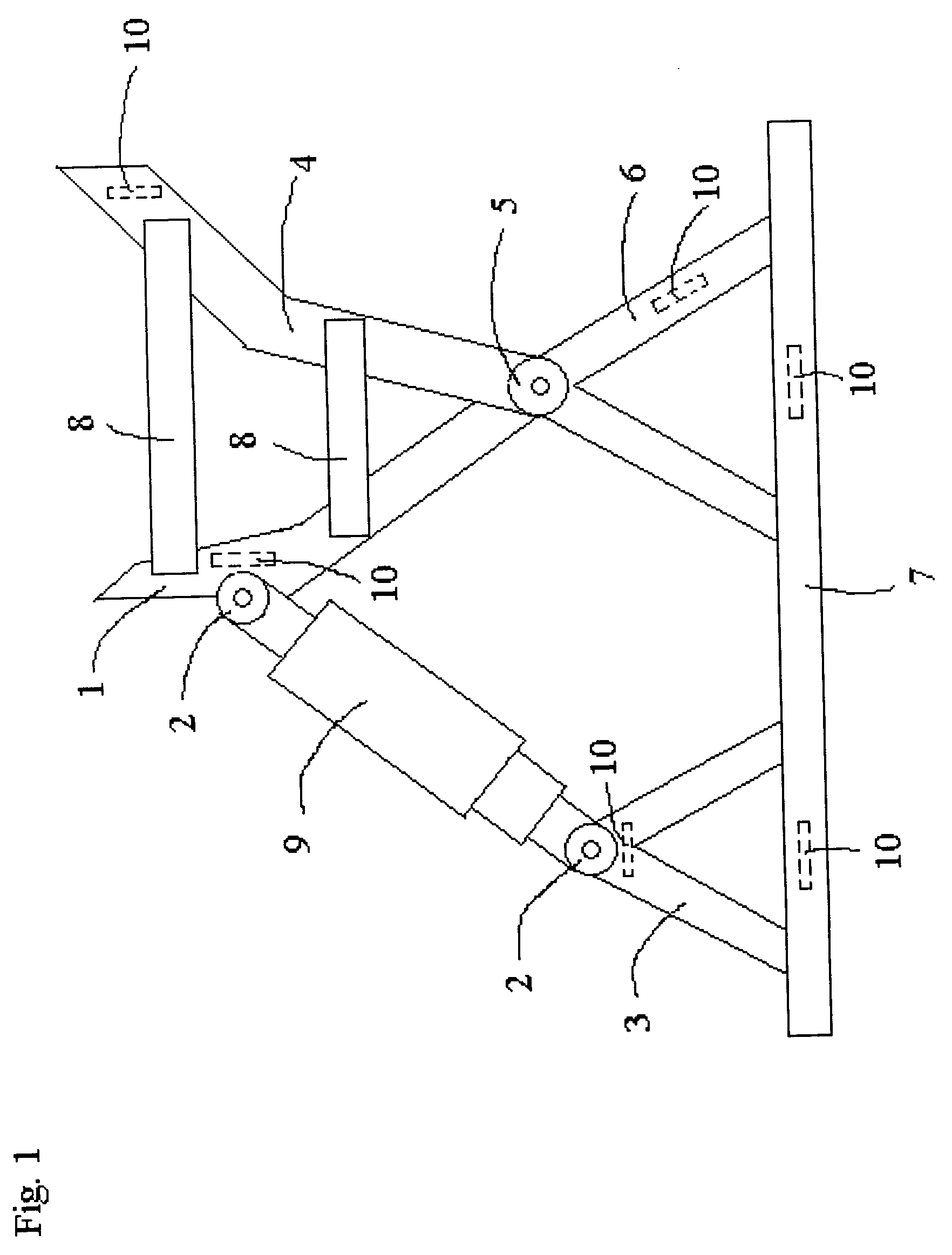

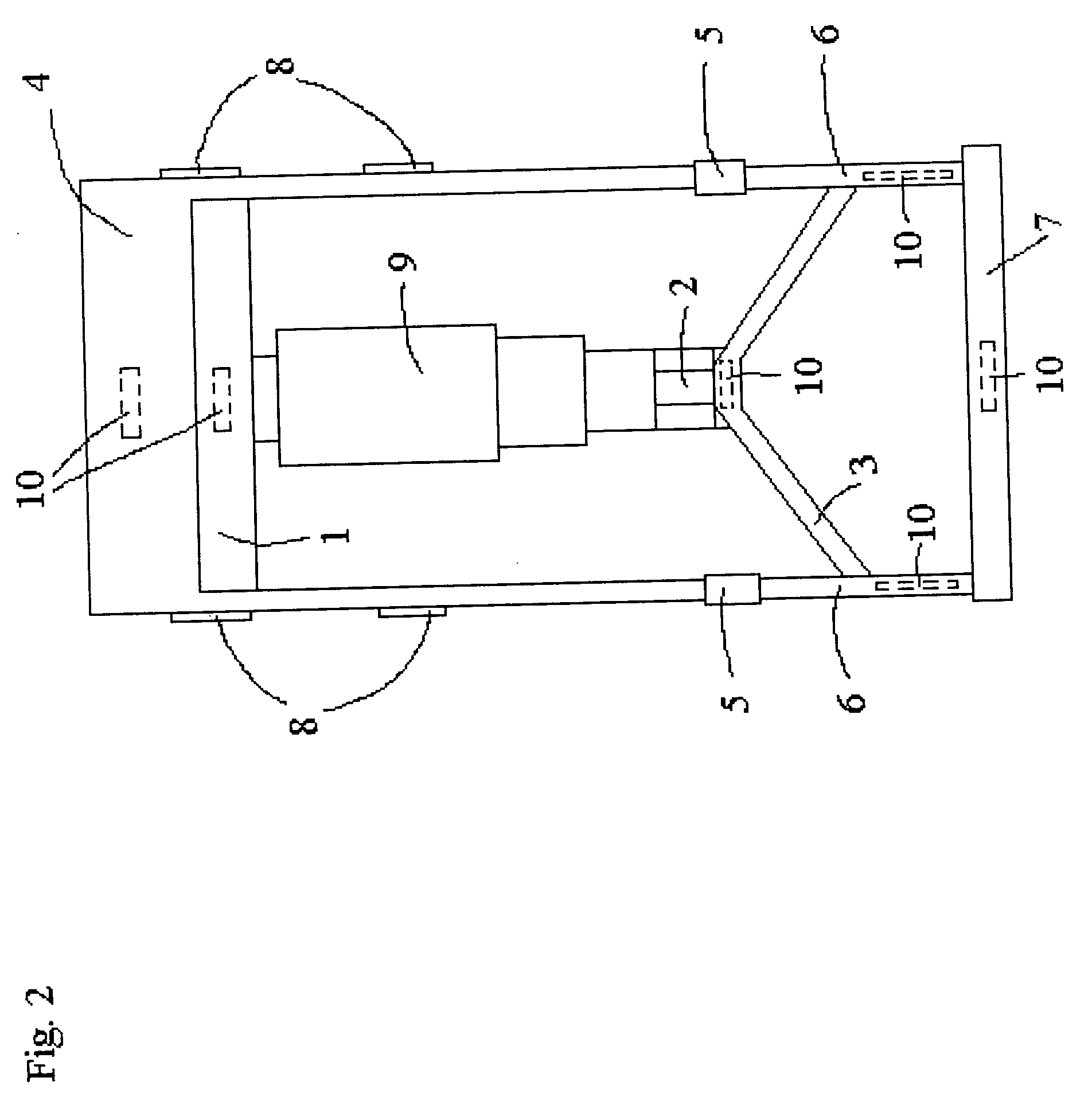

[0016] In its preferred embodiment, this invention is a combination of a rigid, pivoting exoskeleton (providing the lateral stiffness and torsional control), a sub-boot (providing padding, thermal insulation, and water-proofing), and a fully adjustable hydraulic shock absorber (providing adjustable fore-aft stiffness, shock absorption, and rebound damping). The object of the invention is to optimize ski boot performance by separating the necessary boot components, allowing them to be designed to optimize different performance characteristics. The exoskeleton as diagrammed would be cast, forged, or machined from aluminum or similar alloy, or it could be cast or formed from plastic, composite material, carbon fiber, or other similar durable, stiff material. In the preferred embodiment, it would have releasable attachments to fasten it to the sub-boot, which in the preferred embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com