Display unit, drive circuit, amorphous silicon thin-film transistor, and method of driving OLED

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

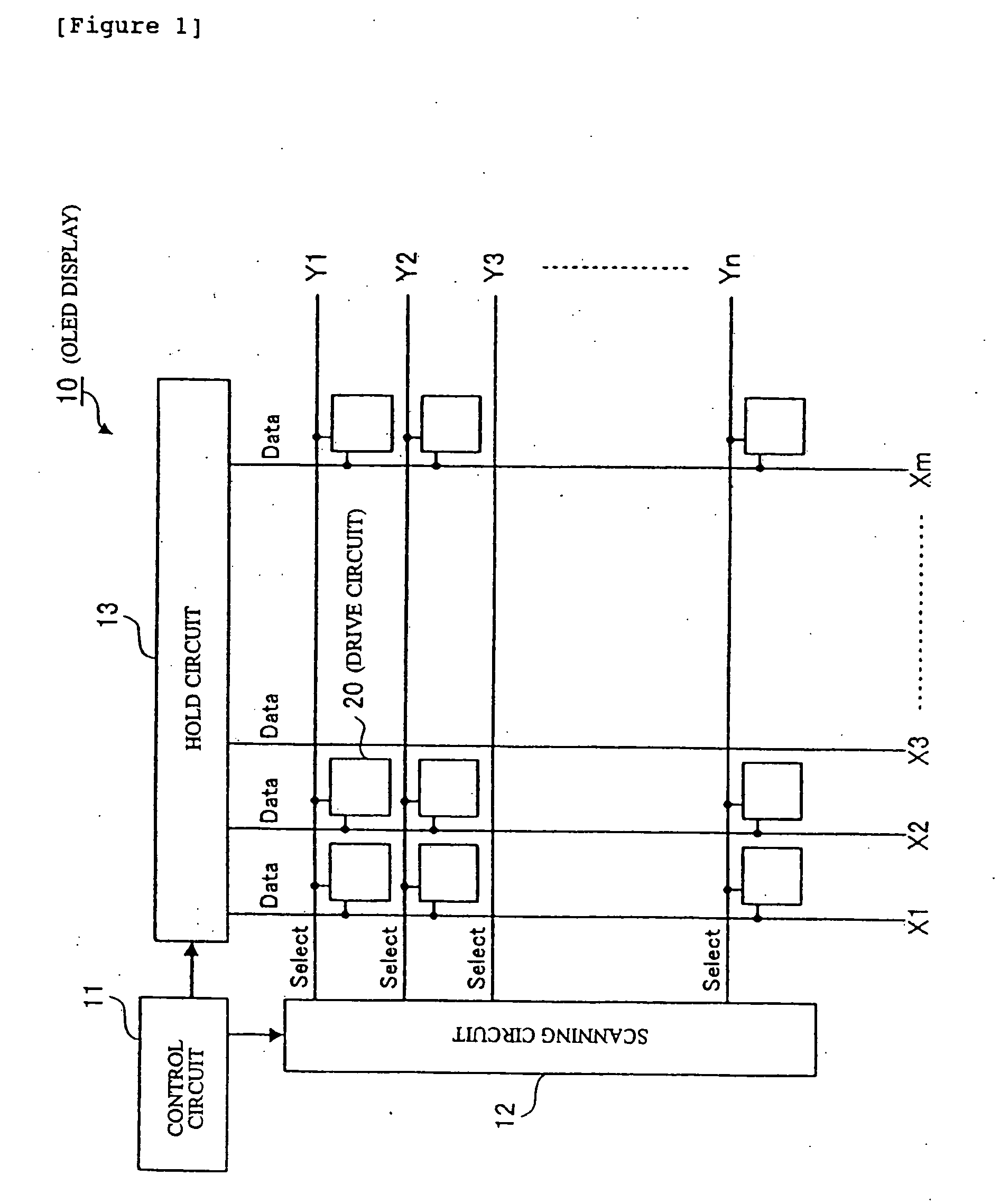

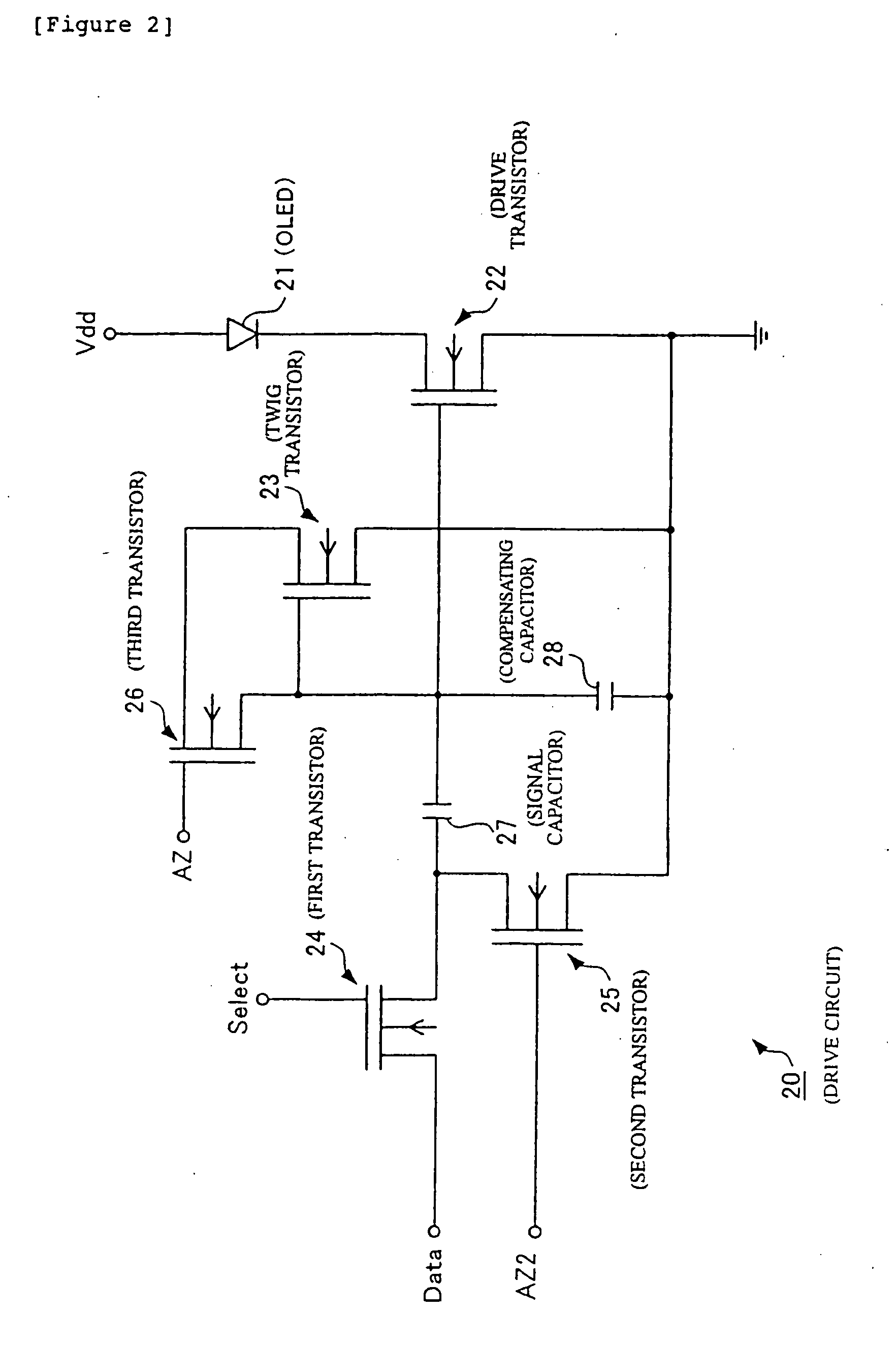

[0037] The present invention will be described in detail with respect to an embodiment thereof with reference to the accompanying drawings.

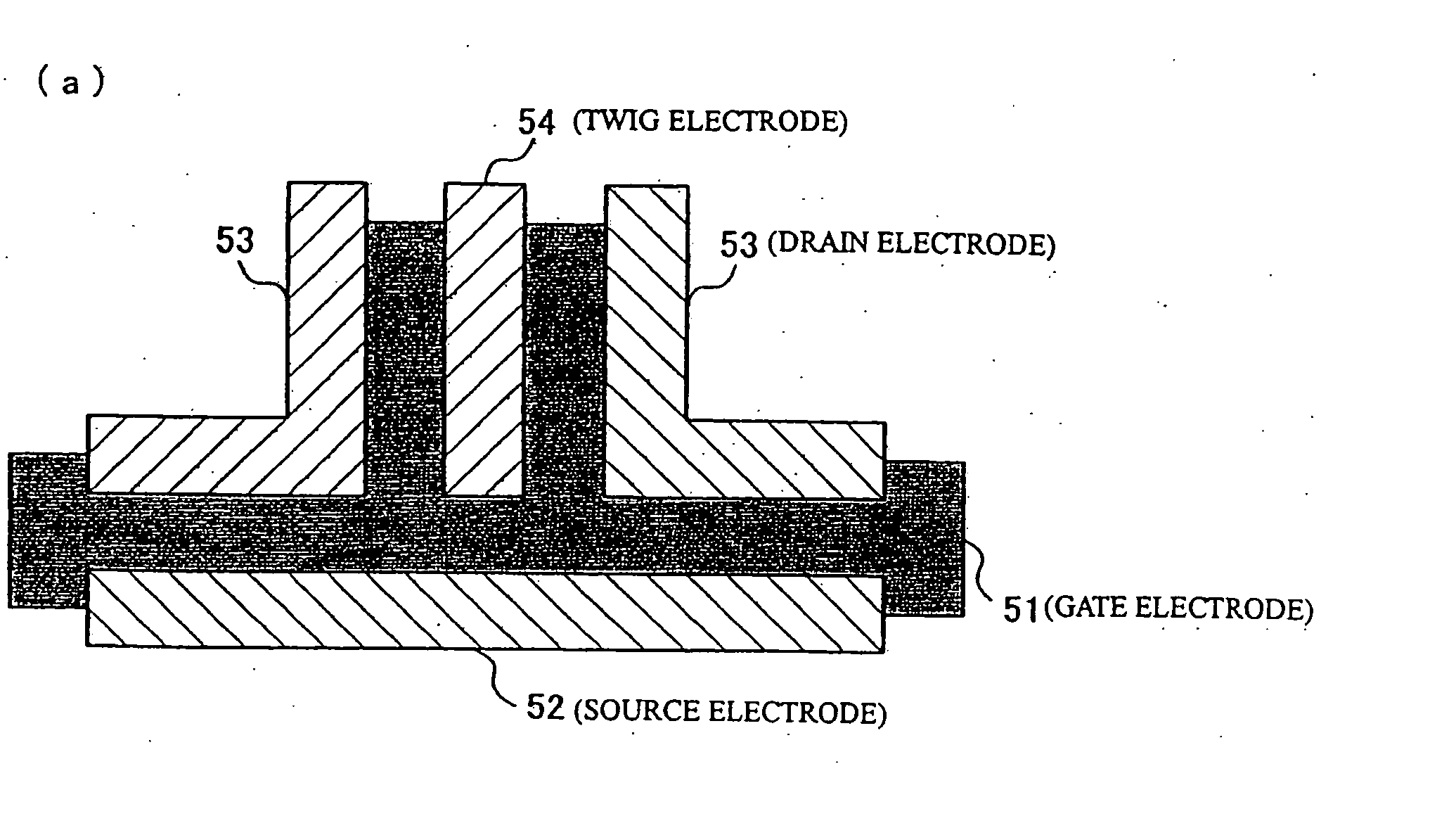

[0038] Description of symbols [0039]10 . . . OLED display [0040]11 . . . Control circuit [0041]12 . . . Scanning circuit [0042]13 . . . Hold circuit [0043]20 . . . Drive circuit [0044]21 . . . Organic light emitting diode (OLED) [0045]22 . . . Drive transistor [0046]23 . . . Twig transistor [0047]24 . . . First transistor [0048]25 . . . Second transistor [0049]26 . . . Third transistor [0050]27 . . . Signal capacitor [0051]28 . . . Compensating capacitor [0052]31 . . . OLED [0053]32 . . . Drive transistor [0054]33 . . . Twig transistor [0055]34 . . . First transistor [0056]35 . . . Second transistor [0057]36 . . . Third transistor [0058]37 . . . Fourth transistor [0059]38 . . . Signal capacitor [0060]39 . . . Compensating capacitor [0061]51 . . . Gate electrode [0062]52 . . . Source electrode [0063]53 . . . Drain electrode [0064]54 . . . Twig el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com