Marine forest structure

a forest structure and structure technology, applied in the field of marine forest structure, can solve the problems of high cost, poor workability, complicated work, etc., and achieve the effects of reducing weight, low cost, and swarming effect of fishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

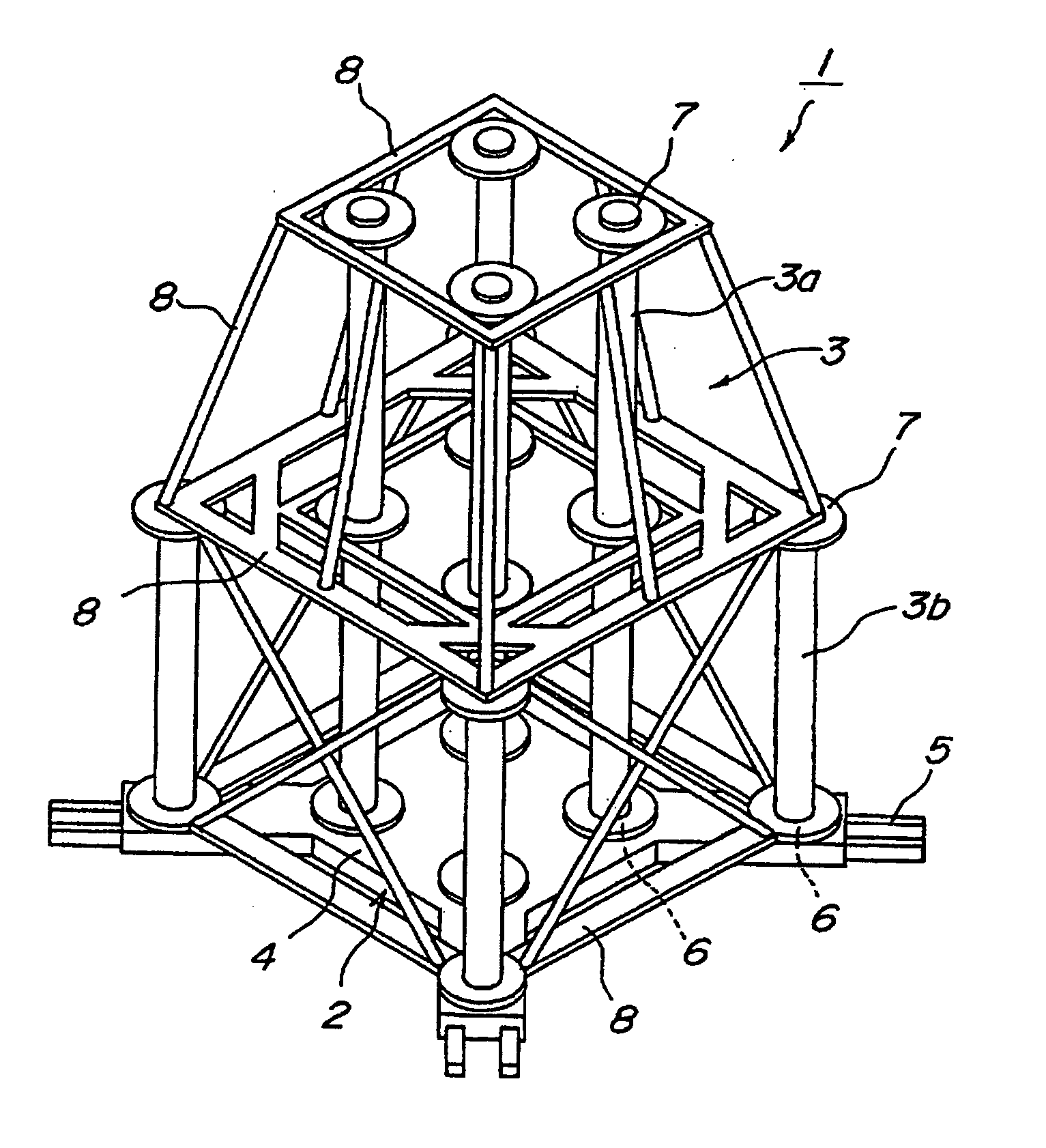

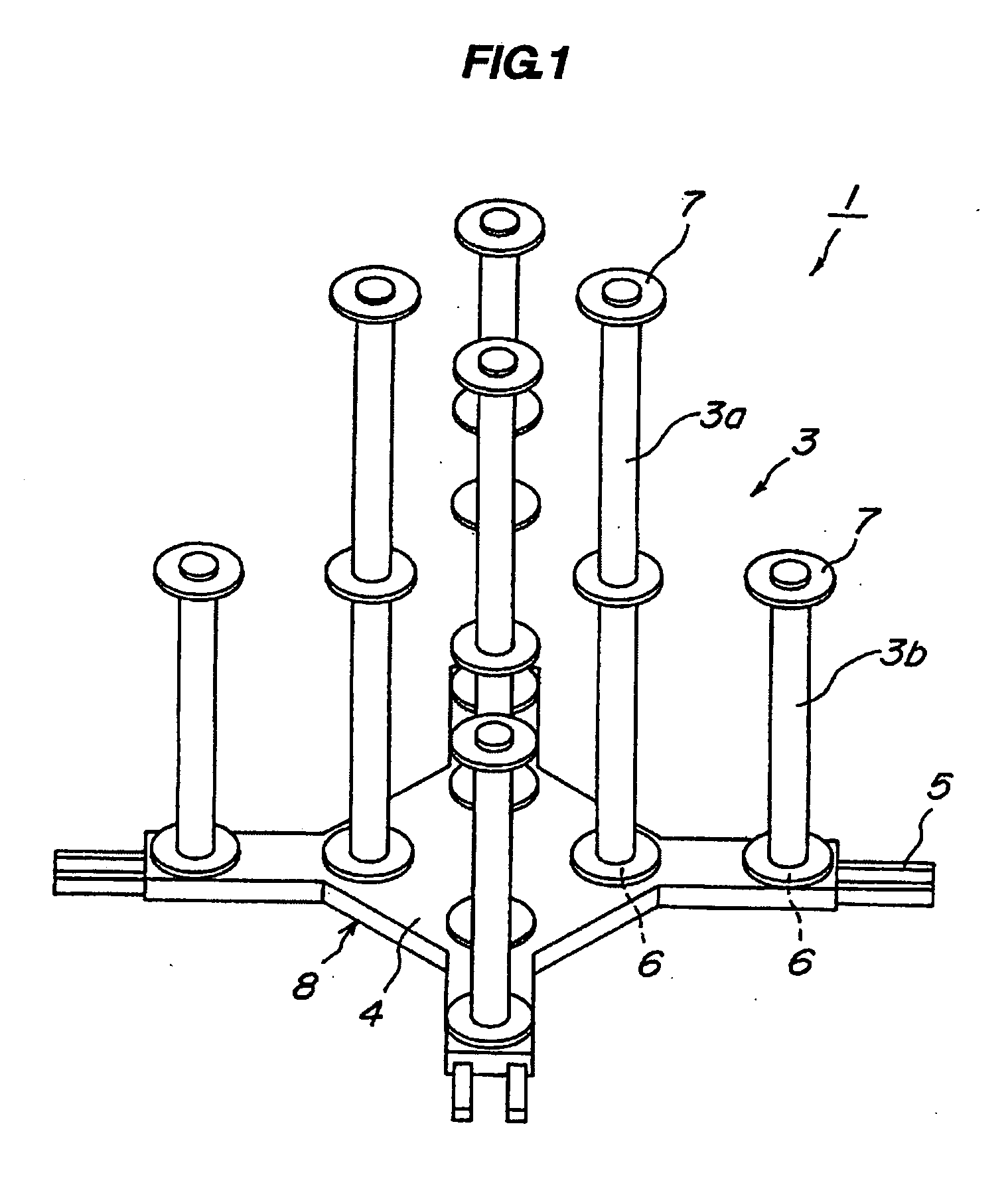

[0048] Referring to FIGS. 1 to 3, a marine forest structure according to the invention will be described. This marine forest structure 1 is basically composed of a base 2 and a plurality of pillar bodies 3 raised from this base 2.

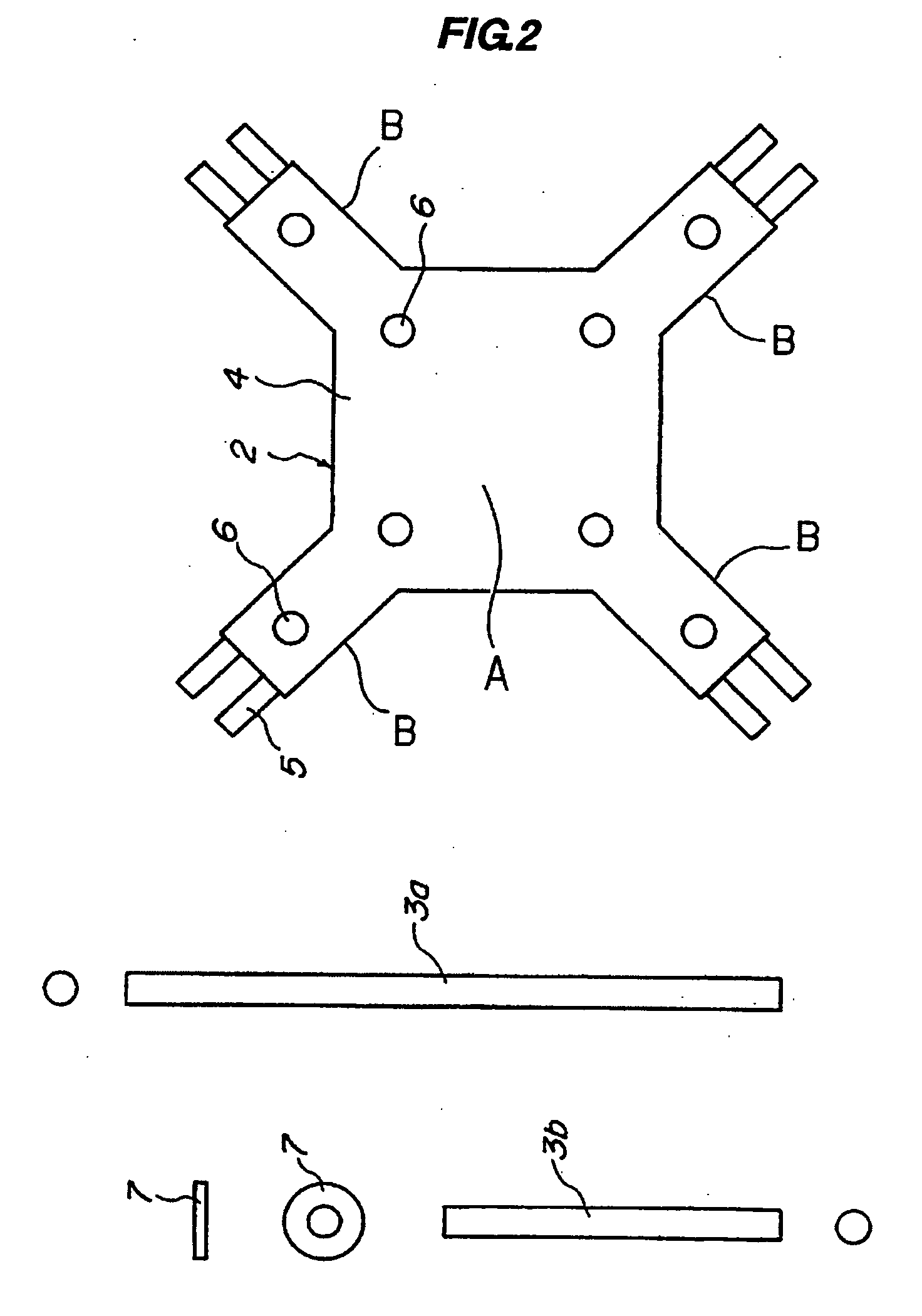

[0049] The base 2 is composed of a rectangular flat plate 4 formed of steel, concrete, or the like and legs 5 protruding from respective corners of this flat plate 4. These legs 5 are formed integrally with the flat plate 4 in advance. These legs 5 plays a role of making the base 2 stable on the bottom of the sea when the marine forest structure 1 is submerged and placed in the sea.

[0050] Holes 6 for raising the pillar bodies 3 respectively are provided in a central part A (central part of the base) and corner parts B (peripheral parts of the base) of the flat plate 4. In the present embodiment, four holes 6 are provided in the central part of the flat plate 4, and one hole 6 is provided on each corner part.

[0051] Steel, concrete, telegraph poles which ha...

second embodiment

[0056] In this second embodiment, pillar bodies 3a raised from the central part of the base 2 have a height of approximately 12 m, and pillar bodies 3b approximately 4 m. Accordingly, the entire height of the marine forest structure 9 is approximately 12.5 m, the bottom side width approximately 12 m, the space volume approximately 330 m3, and the entire weight approximately 36.7 t. This marine forest structure 9 can be effectively employed in a sea area which has a deep depth.

[0057] Referring to FIGS. 5 to 7, a marine forest structure 10 of the third embodiment according to the invention will be described. Although scrap telegraph poles are effectively utilized for the pillar bodies 3 in the above-described first and second embodiments, in the marine forest structure 10 of this third embodiment, thinning wood of mountains and forests is effectively utilized instead of scrap telegraph poles.

third embodiment

[0058] In describing the marine forest structure 10 of the third embodiment with reference to the drawing, pillar bodies 11a are thinning wood whose height is approximately 12 m, and pillar bodies 11b are thinning wood whose height is approximately 4 m. A plurality of pillar bodies 11a are respectively raised from four holes 6 of a central part A (central part of the base) of a flat plate 4 of a base 2, and pillar bodies 11b are raised from holes 6 of corner parts B (peripheral parts of the base) of the flat plate 4. The pillar body 11a raised from the central part A can be constructed by coupling the pillar bodies 11b which has a low height.

[0059] Although the number of pillar bodies 11a, 11b raised from the respective holes 6 changes depending on the diameters of the pillar bodies, generally approximately four to twelve pillar bodies 11a, 11b can be inserted into the respective holes 6 to be raised therefrom. The positions of the lower end portions of the plural pillar bodies 11a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com