Gamma dash precipitation strengthened platinum group element-added ni-based superalloy designing support program and gamma dash precipitation strengthened plantinum group element-added ni-based superalloy designing support apparatus

a technology of superalloy and precipitation, which is applied in the direction of heat treatment apparatus, instruments, manufacturing tools, etc., can solve the problems of not being applicable to platinum group elements, consuming a tremendous amount of labor and cost, etc., and achieves the effect of facilitating and efficiently performing the structural factor calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

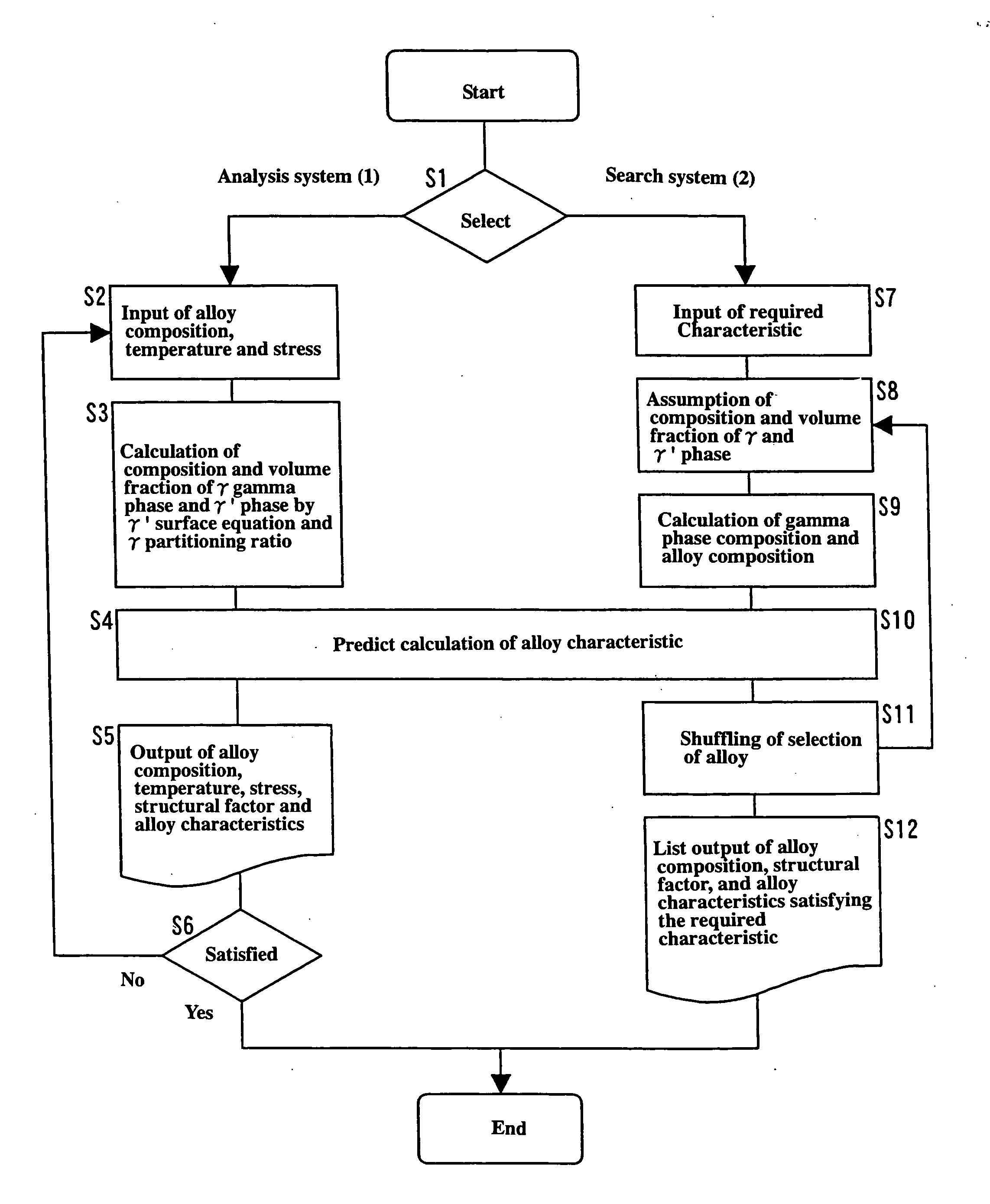

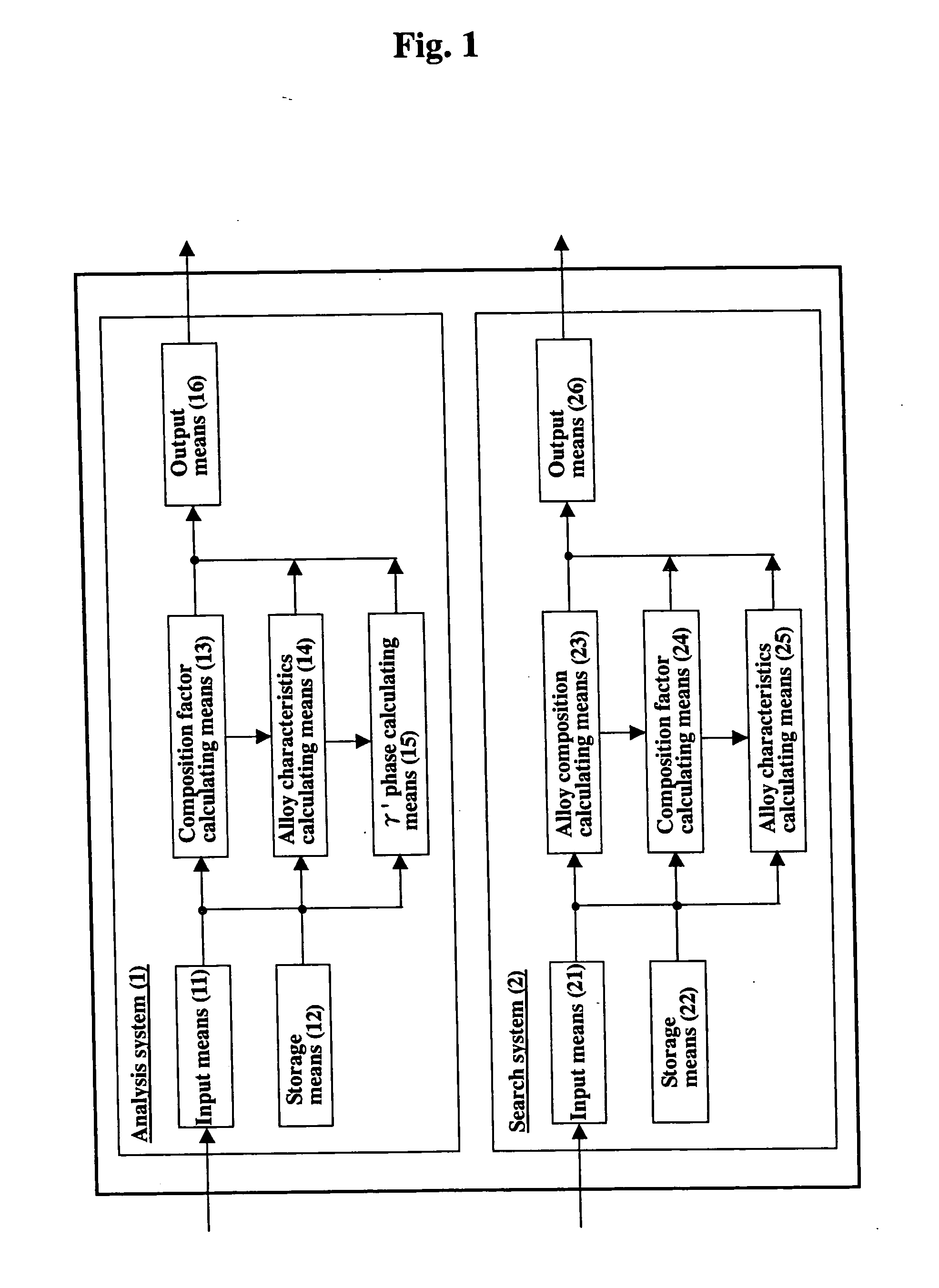

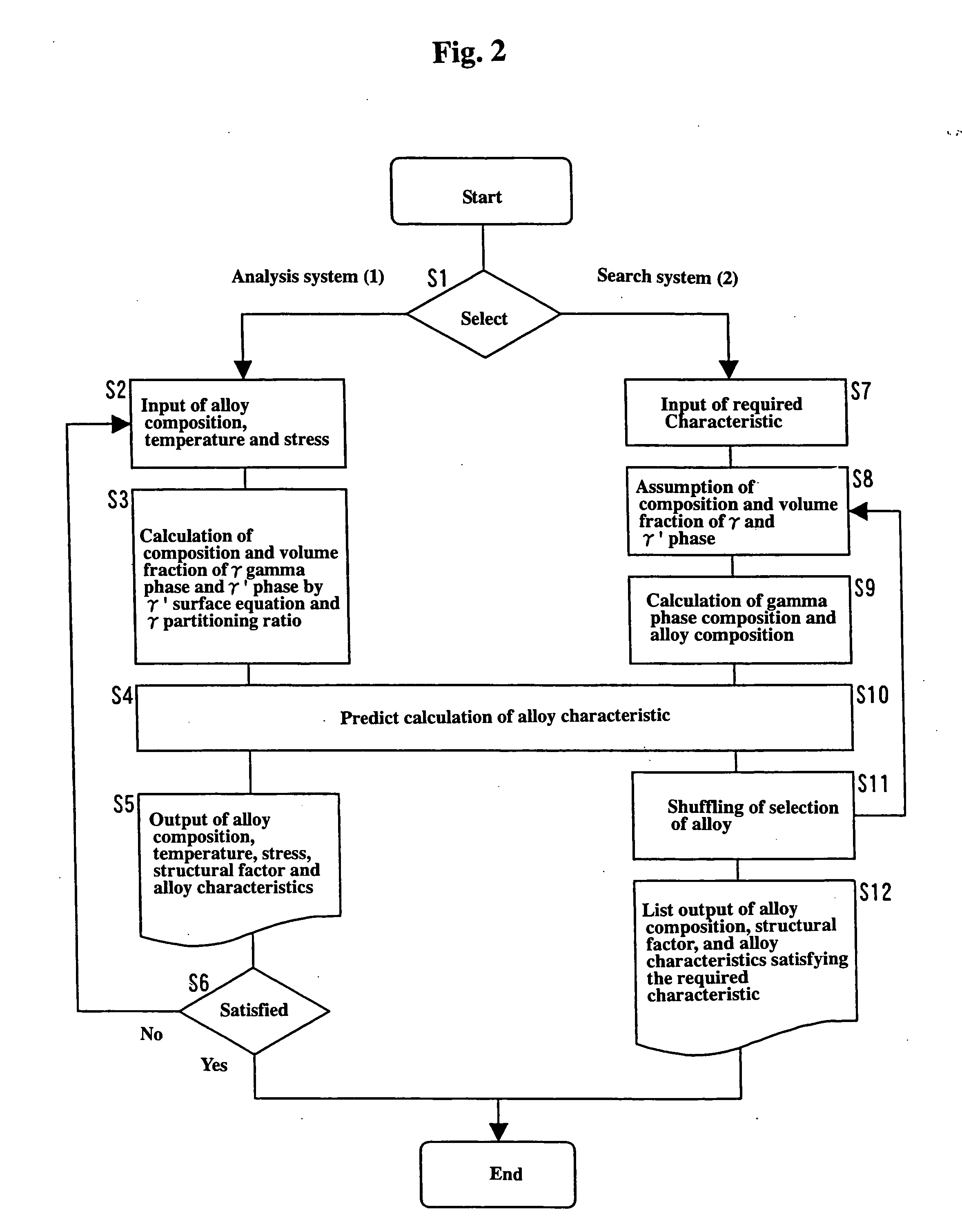

Method used

Image

Examples

embodiments

Analysis Embodiment

[0063] Inputting the composition of TMS-138 alloy, the equilibrium state and alloy characteristics in 900° C.−392 MPa and 1100° C.−137 MPa were calculated. FIG. 5 is an example of printed output of the results. Symbols in the diagram are defined as shown in Table 2.

TABLE 2StructuralSymbolfactor or CharacteristicUnitUnit or State(WT %)Alloy compositionwt %—(AT %)Alloy compositionatom %—GPγ′ phase compositionatom %workingtemperature (° C.)Gγ phase compositionatom %workingtemperature (° C.)Fraction. GPγ′ phase volume fractionat amountworkingtemperature (° C.)Lat. GPγ phase lattice constantÅworkingtemperature (° C.)Lat. Gγ phase lattice constantÅworkingtemperature (° C.)Lat. MisfitLattice misfit° C.—LiqLiquidus temperature° C.—Sol1Solidus temperature° C.—Sol2Incipient melting° C.—temperatureSolvComplete solid solution° C.—temperatureWindowComplete solid solution° C.—temperature widthSIsolubility limit index—900° C.DensitySpecific gravityg / cm2roomtemperature (° C.)E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com