Low-voc aqueous coating compositions with excellent freeze-thaw stability

a technology of aqueous coating composition and freeze-thaw stability, which is applied in the direction of coating, emulsion paint, electrochemical generator, etc., can solve the problems of increasing the open time of latex paint and becoming more and more undesirable, and achieve excellent freeze-thaw stability and lower voc levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 (

E1)

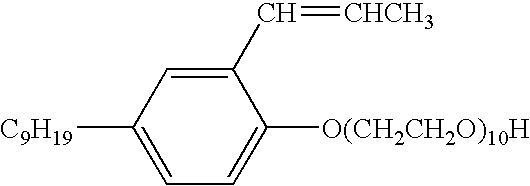

[0025] Example 1 illustrates the preparation of a polymer dispersion containing 2.0% (weight percent of active material based on dry polymer weight) NOIGEN® RN-10 surfactant (commercially available from Montello, Inc. representing Dai-lchi Kogyo Seiyaku Co., Ltd.). NOIGEN® RN-10 surfactant has the following structure:

[0026] A monomer pre-emulsion was prepared by emulsifying 264 parts water, 37.5 parts CALSOFT® L-40 surfactant (a sodium linear or branched alkyl benzene sulfonate surfactant commercially available from Pilot Chemical), 20.0 parts NOIGEN® RN-10 surfactant, 15.0 parts NaOH solution (10% solution in water), 7.5 parts itaconic acid, 20 parts ureido methacrylate, 511.2 parts n-butyl acrylate and 461.0 parts methyl methacrylate. The initiator solution was prepared by dissolving 2.5 parts ammonium persulfate in 47.5 parts water. A 2-liter stirred glass reactor filled with 272.4 parts deionized water and 3.14 parts of a 33% polystyrene seed latex was purged with nitrogen ...

example 2 (

E2)

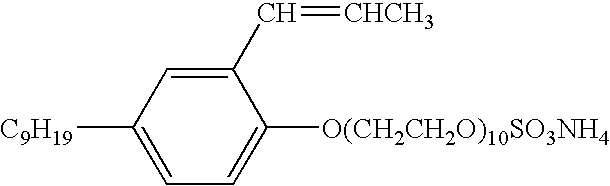

[0028] Example 2 illustrates the preparation of a polymer dispersion containing 2.0% (weight percent of active material based on dry polymer weight) HITENOL® BC-10 surfactant (commercially available from Montello, Inc. representing Dai-lchi Kogyo Seiyaku Co., Ltd.). HITENOL® BC-10 surfactant has the following structure:

[0029] The ingredients and process used for synthesis were the same as used in Example 1 except 20.0 parts of HITENOL® BC-10 surfactant was used instead of NOIGEN® RN-10 surfactant. The resulting polymer dispersion had a solids content of 60.5% and a diameter of 280 nm by photocorrelation spectroscopy.

example 3 (

E3)

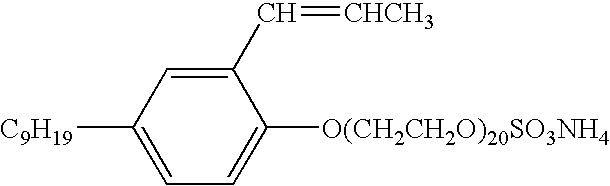

[0030] Example 3 illustrates the preparation of a polymer dispersion containing 2.0% (weight percent of active material based on dry polymer weight) HITENOL® BC-20 surfactant (commercially available from Montello, Inc. representing Dai-lchi Kogyo Seiyaku Co., Ltd.). HITENOL® BC-20 surfactant has the following structure:

[0031] The ingredients and process used for synthesis were the same as used in Example 1 except 20.0 parts of HITENOL® BC-20 surfactant was used instead of NOIGEN®) RN-10 surfactant. The resulting polymer dispersion had a solids content of 59.8% and a diameter of 280 nm by photocorrelation spectroscopy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

| mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com