Vac-veova emulsion and preparation method thereof

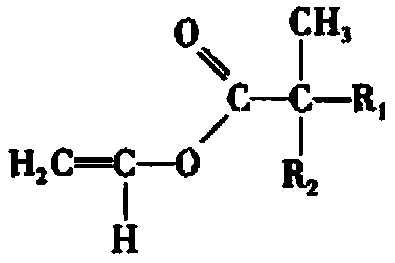

The technology of vinegar tertiary emulsion and emulsifier, which is applied in the field of coatings, can solve the problems of difficulty in realizing freeze-thaw stability and scrub resistance, and achieve the effects of improving scrub resistance, improving contact and function, and improving film-forming properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Another embodiment of the present invention provides a method for preparing any of the above-mentioned tertiary vinegar emulsions, which may specifically include the following steps:

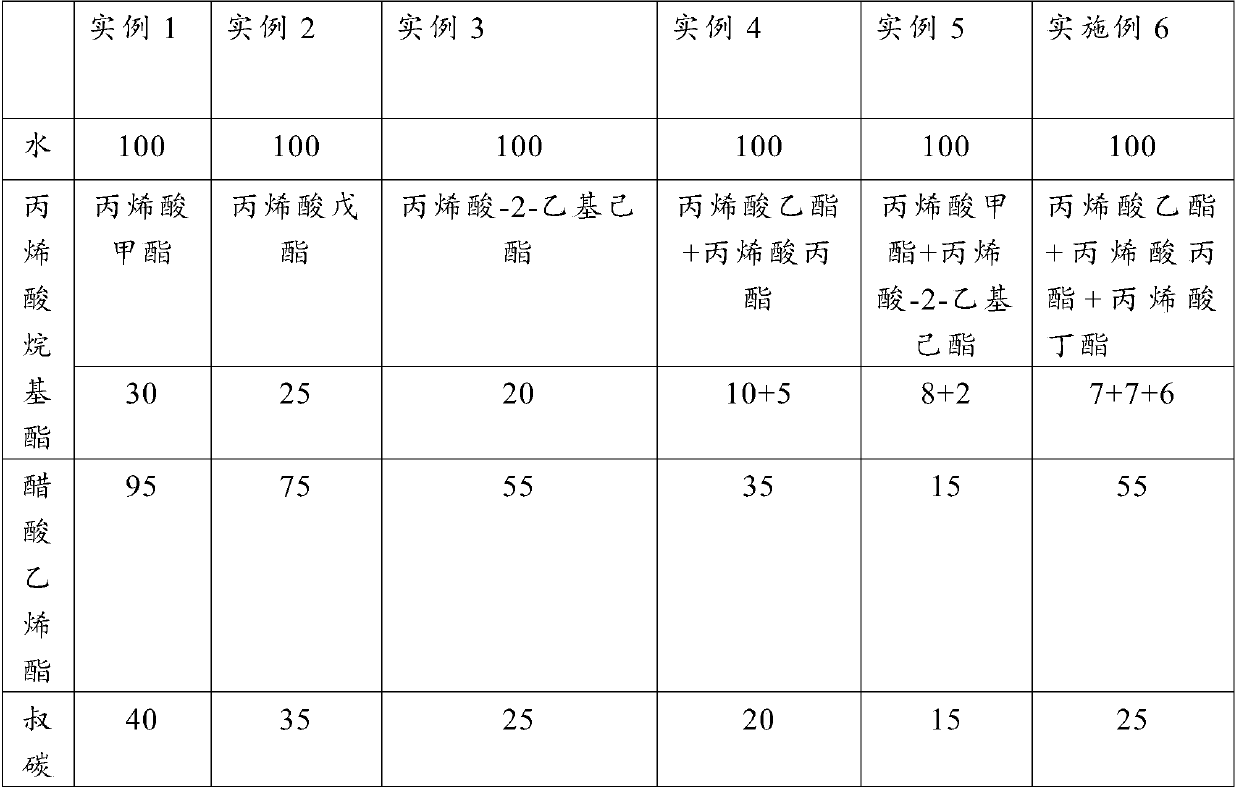

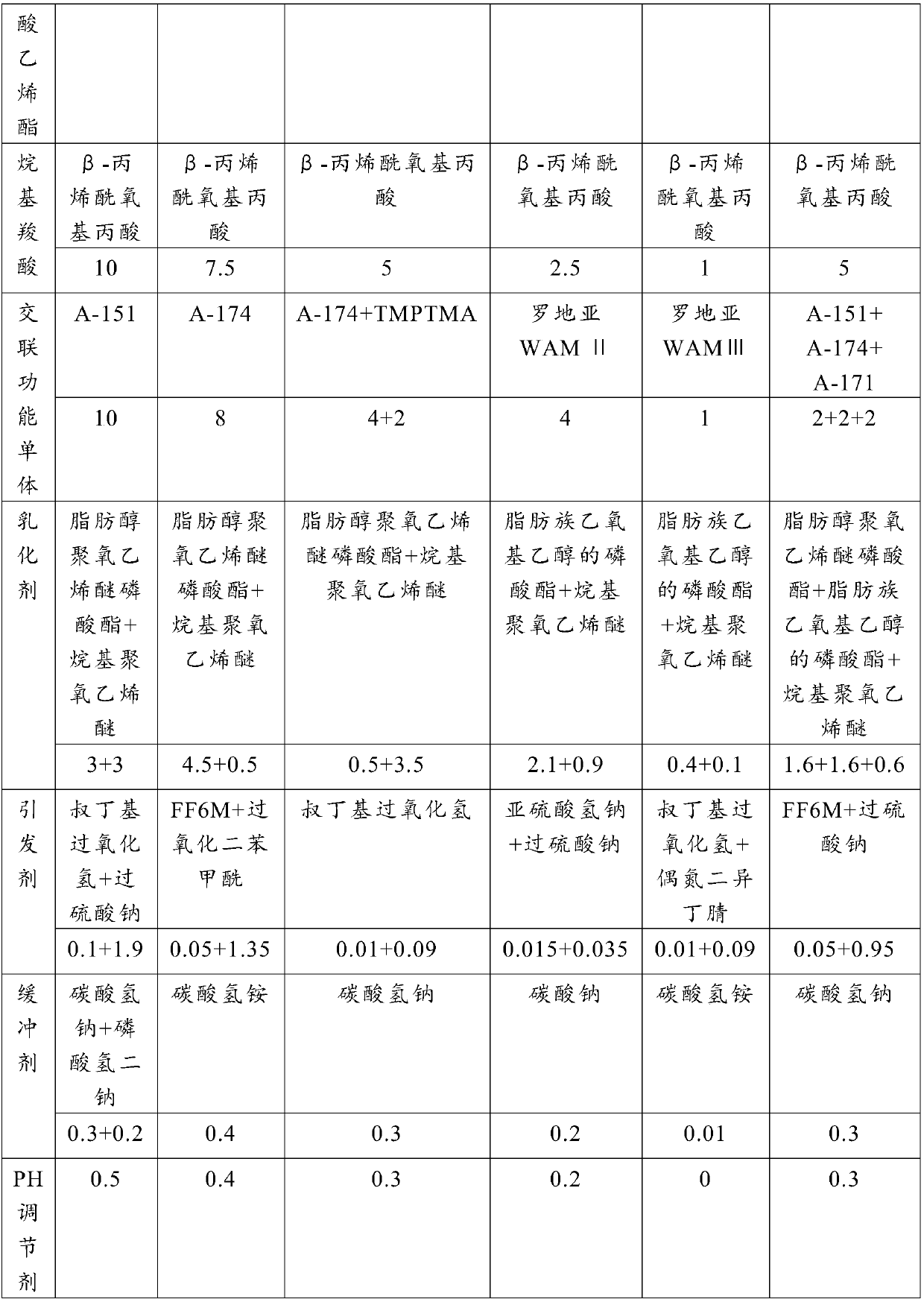

[0054] S1. Preparation of monomer solution A: 0.5-4 parts of emulsifier; 10-30 parts of alkyl acrylate; 15-95 parts of vinyl acetate; 15-40 parts of vinyl tertiary carbonate; parts; 2-10 parts of cross-linking functional monomers are put into the dripping tank in a stirring state and stirred for 10 minutes; 10-60 minutes for standby;

[0055] S2. Preparation of monomer solution B: Put the remaining amount of alkyl acrylate, vinyl acetate, vinyl tert-carbonate, alkyl carboxylic acid, and cross-linking functional monomer into the drop tank in a stirring state and stir for 10 minutes ;

[0056] S3. Preparation of base material liquid C: put 4-6 parts of emulsifier and 5-55% of the total amount of deionized water into a reactor equipped with a stirrer, condenser, and constant-flow pump feed...

Embodiment 1

[0069] The components and their mass fractions are shown in Table 1.

[0070] 30 parts of alkyl acrylate; 95 parts of vinyl acetate; 40 parts of vinyl tert-carbonate; 10 parts of alkyl carboxylic acid; 10 parts of crosslinking functional monomer; 6 parts of emulsifier; 2 parts of initiator; 0.5 part of buffer; PH regulator 0.5 parts; deionized to 100 parts.

[0071]A. Preparation of monomer solution A: 2 parts of emulsifier; 30 parts of alkyl acrylate; 90 parts of vinyl acetate; 39 parts of vinyl tertiary carbonate; 9.9 parts of alkyl carboxylic acid; In the stirring state, put them into the dropping tank one by one and stir for 10 minutes; then put 30% of the total amount of deionized water into the dropping tank, and put in the buffer at the same time, and continue to disperse for 60 minutes for later use.

[0072] B. Preparation of monomer solution B: put 0 part of alkyl acrylate; 5 parts of vinyl acetate; 1 part of vinyl tertiary carbonate; 0.1 part of alkyl carboxylic ac...

Embodiment 2

[0081] The components and their mass fractions are shown in Table 1.

[0082] 25 parts of alkyl acrylate; 75 parts of vinyl acetate; 35 parts of vinyl tertiary carbonate; 7.5 parts of alkyl carboxylic acid; 8 parts of cross-linking functional monomer; 5 parts of emulsifier; 1.5 parts of initiator; PH regulator 0.4 parts; deionized to 100 parts.

[0083] A. Preparation of monomer solution A: 4 parts of emulsifier; 15 parts of alkyl acrylate; 60 parts of vinyl acetate; 20 parts of vinyl tertiary carbonate; 7 parts of alkyl carboxylic acid; In the stirring state, put them into the dropping tank one by one and stir for 10 minutes; then put 40% of the total amount of deionized water into the dropping tank, and put in the buffer at the same time, and continue to disperse for 50 minutes for later use.

[0084] B. Preparation of monomer solution B: put 10 parts of alkyl acrylate; 15 parts of vinyl acetate; 15 parts of vinyl tertiary carbonate; 0.5 parts of alkyl carboxylic acid; Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com