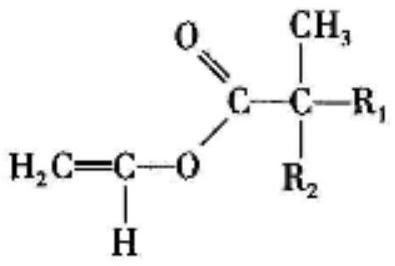

A kind of vinegar tert emulsion and preparation method thereof

A technology of tertiary vinegar emulsion and emulsifier, which is applied in the field of coatings, can solve the problems of freeze-thaw stability and scrub resistance, and achieve the effects of improving scrub resistance, performance improvement, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Another embodiment of the present invention provides a method for preparing any of the above-mentioned tertiary vinegar emulsions, which may specifically include the following steps:

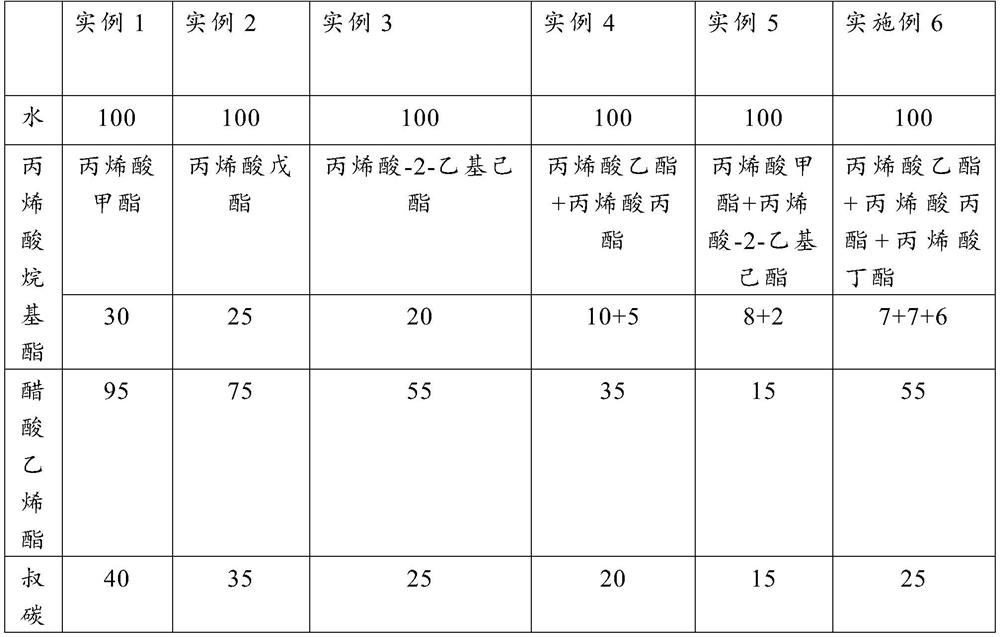

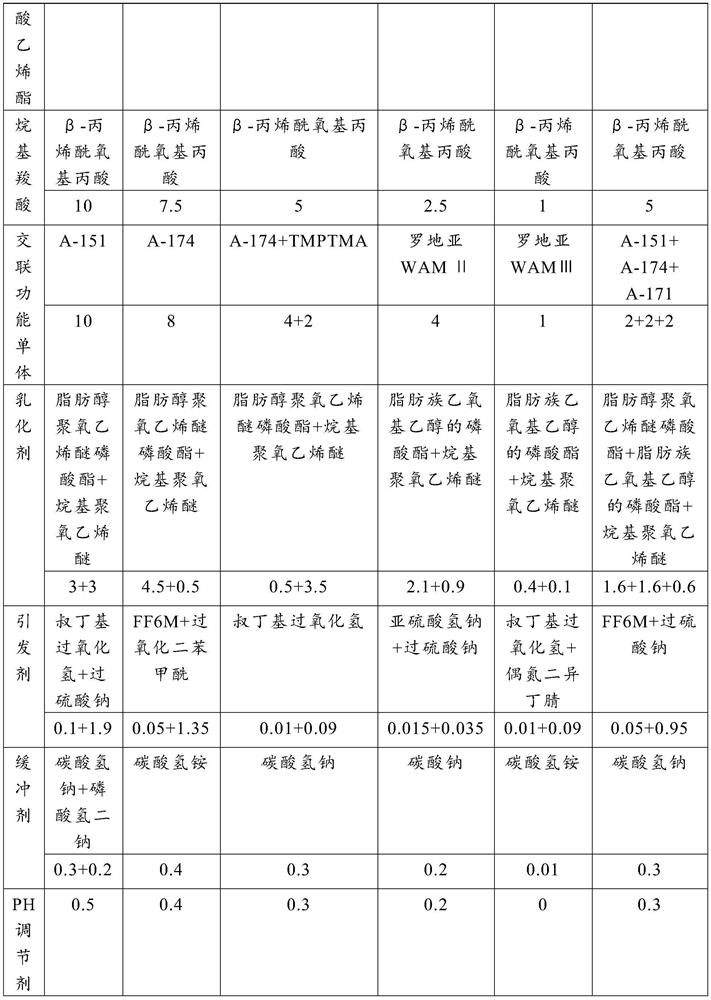

[0054] S1. Preparation of monomer solution A: 0.5-4 parts of emulsifier; 10-30 parts of alkyl acrylate; 15-95 parts of vinyl acetate; 15-40 parts of vinyl tertiary carbonate; parts; 2-10 parts of cross-linking functional monomers are put into the dripping tank in a stirring state and stirred for 10 minutes; 10-60 minutes for standby;

[0055] S2. Preparation of monomer solution B: Put the remaining amount of alkyl acrylate, vinyl acetate, vinyl tert-carbonate, alkyl carboxylic acid, and cross-linking functional monomer into the drop tank in a stirring state and stir for 10 minutes ;

[0056] S3. Preparation of base material liquid C: put 4-6 parts of emulsifier and 5-55% of the total amount of deionized water into a reactor equipped with a stirrer, condenser, and constant-flow pump feed...

Embodiment 1

[0069] The components and their mass fractions are shown in Table 1.

[0070] 30 parts of alkyl acrylate; 95 parts of vinyl acetate; 40 parts of vinyl tert-carbonate; 10 parts of alkyl carboxylic acid; 10 parts of crosslinking functional monomer; 6 parts of emulsifier; 2 parts of initiator; 0.5 part of buffer; PH regulator 0.5 parts; deionized to 100 parts.

[0071]A. Preparation of monomer solution A: 2 parts of emulsifier; 30 parts of alkyl acrylate; 90 parts of vinyl acetate; 39 parts of vinyl tertiary carbonate; 9.9 parts of alkyl carboxylic acid; In the stirring state, put them into the dropping tank one by one and stir for 10 minutes; then put 30% of the total amount of deionized water into the dropping tank, and put in the buffer at the same time, and continue to disperse for 60 minutes for later use.

[0072] B. Preparation of monomer solution B: put 0 part of alkyl acrylate; 5 parts of vinyl acetate; 1 part of vinyl tertiary carbonate; 0.1 part of alkyl carboxylic ac...

Embodiment 2

[0081] The components and their mass fractions are shown in Table 1.

[0082] 25 parts of alkyl acrylate; 75 parts of vinyl acetate; 35 parts of vinyl tertiary carbonate; 7.5 parts of alkyl carboxylic acid; 8 parts of cross-linking functional monomer; 5 parts of emulsifier; 1.5 parts of initiator; PH regulator 0.4 parts; deionized to 100 parts.

[0083] A. Preparation of monomer solution A: 4 parts of emulsifier; 15 parts of alkyl acrylate; 60 parts of vinyl acetate; 20 parts of vinyl tertiary carbonate; 7 parts of alkyl carboxylic acid; In the stirring state, put them into the dropping tank one by one and stir for 10 minutes; then put 40% of the total amount of deionized water into the dropping tank, and put in the buffer at the same time, and continue to disperse for 50 minutes for later use.

[0084] B. Preparation of monomer solution B: put 10 parts of alkyl acrylate; 15 parts of vinyl acetate; 15 parts of vinyl tertiary carbonate; 0.5 parts of alkyl carboxylic acid; Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com