Infrared emitting apparatus

a technology of infrared radiation and emitter, which is applied in the direction of stoves, combustion types, ranges, etc., can solve the problems of most flare-ups, uncontrolled burning, and high fire intensity, and achieve the effect of enhancing the emission of infrared radiation and keeping the temperature of the emitter relatively high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

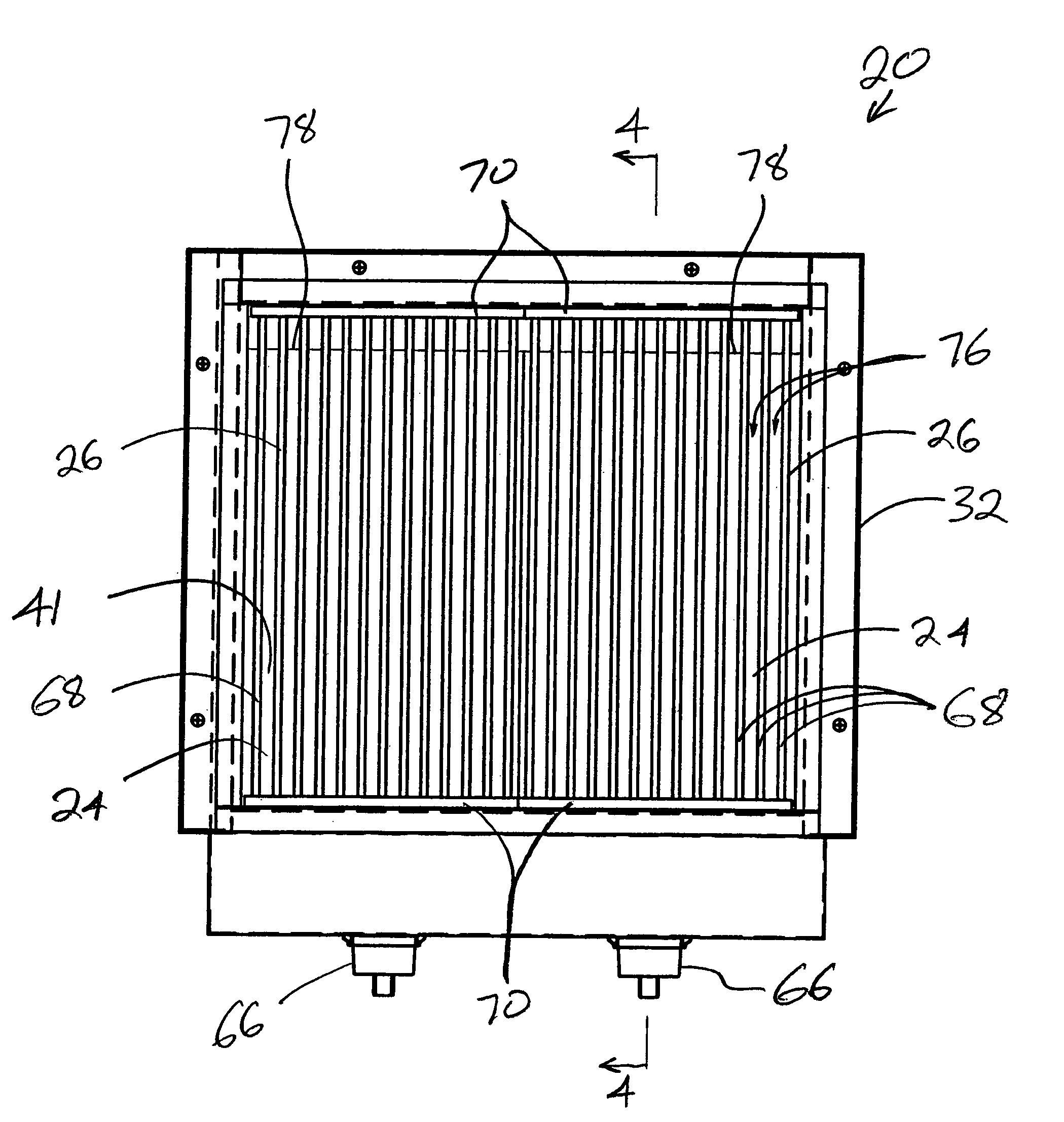

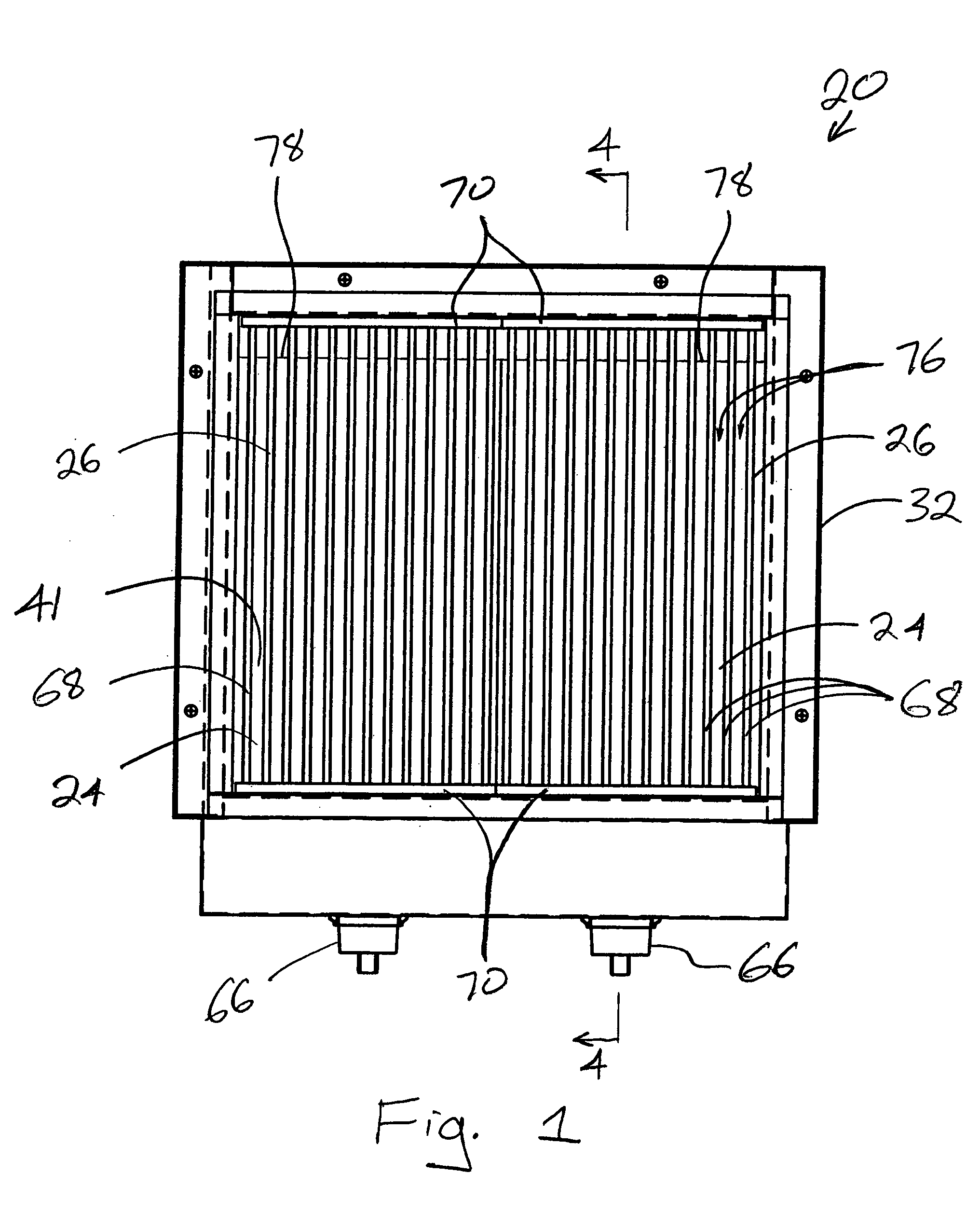

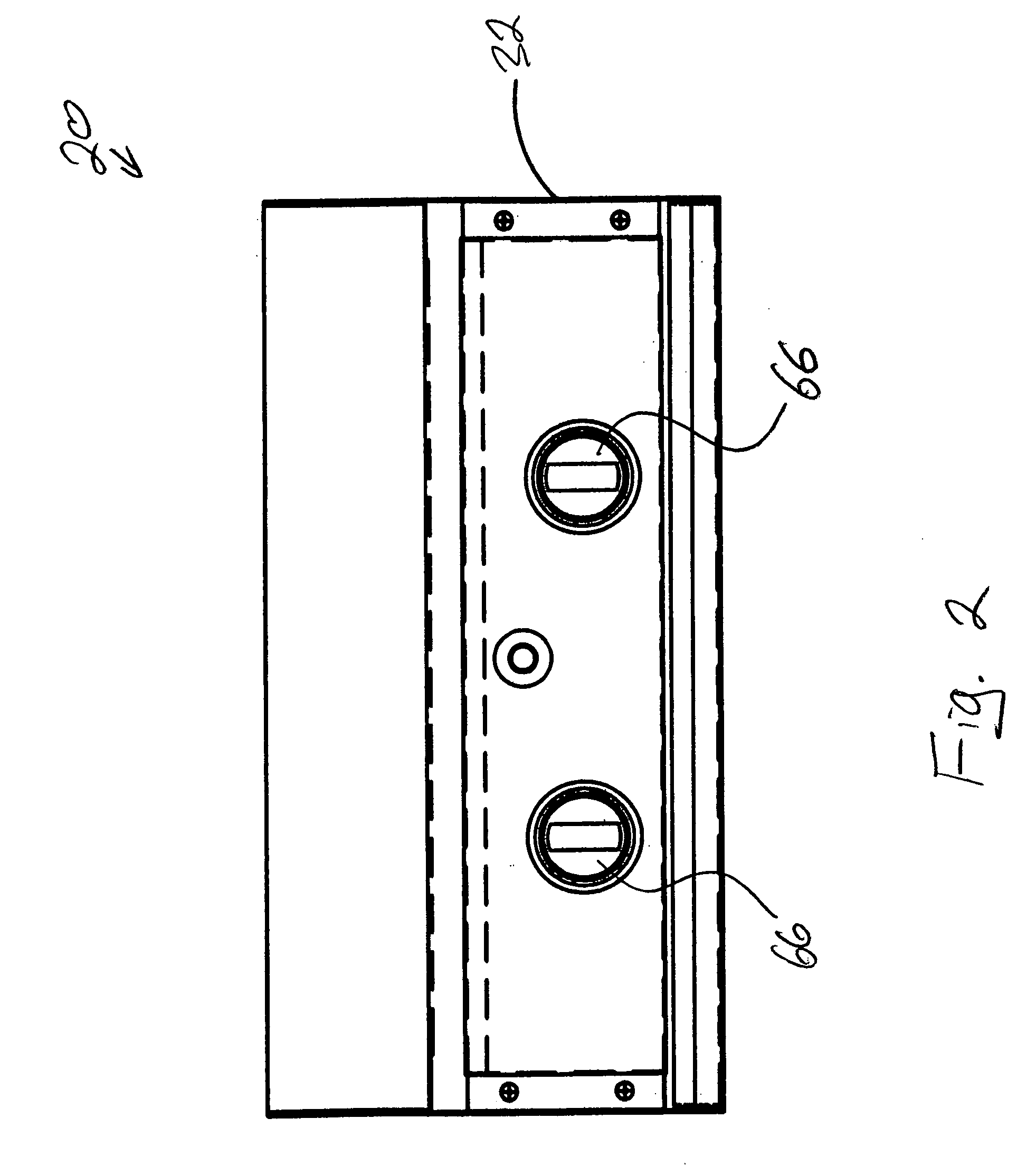

[0024] Referring now in greater detail to the drawings, in which like numerals refer to like parts throughout the several views, FIGS. 1-4 schematically illustrate a cooking apparatus 20 (e.g., broiler or grill) that includes two sources of energy (e.g., heating units 22), with each of the heating units being respectively associated with an infrared radiant energy emitter 24 and a grid 26, in accordance with an exemplary embodiment of the present invention. The heating units 22 function to heat the energy emitters 24 so that the energy emitters emit infrared radiation, such as for cooking (e.g., broiling) food on the grids 26. The energy emitters 24 can be heated in any conventional manner. For example, the heating units 22 can be gas burners or electrical heating elements, or the like. Nonetheless and not for the purpose of narrowing the scope of the present invention, the heating units 22 are described herein as being infrared radiant burner units 22.

[0025] Very generally describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com