Plastic sheet product offering matte appearance and method of preparation

a technology of plastic sheets and products, applied in the field of plastic sheets products, can solve the problems of loss of texture, limited predictability and consequent uniformity, frequent replacement of rolls, etc., and achieve the effects of less cleaning maintenance, less porous, and inexpensive preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

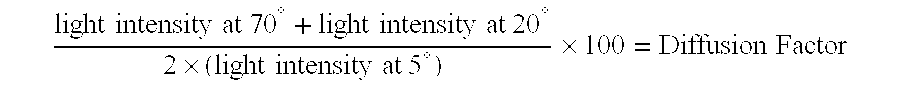

Image

Examples

example 1

[0023] In this example, a plastic sheet product containing one capstock layer bonded to the core layer was prepared. The first thermoplastic polymer used for the core layer and the second thermoplastic polymer used for the capstock layer were the same: a copolymer of about 94 wt. % methyl methacrylate and about 6 wt. % methyl acrylate having a melt index of 2.1, a weight average molecular weight of 150,000 and a refractive index of 1.490. The amount of the first thermoplastic composition for the core layer in relation to the second thermoplastic polymer for the capstock layer was such that, after feedblock coextrusion of the two layers, the core layer had a thickness of 5.75 mm and the capstock layer had a thickness of 250 microns. Particles comprising beads of a crosslinked polymethyl methacrylate with a refractive index of 1.52 and average particle diameters of about 40 microns were combined with the second thermoplastic polymer in an amount of 25 wt. % of the beads.

[0024] The eq...

example 2

[0026] Example 1 was repeated so as to prepare a plastic sheet product with capstock layers on both faces of the core layer and a total thickness of about 6 mm. Accordingly, the composition of the core layer and the capstock layer were the same as those of Example 1, and the general manufacturing procedure was also the same, with the exception that the flow channels on both sides of the feed block were opened so that the capstock layer composition could flow to both faces of the core layer. The amount of the first thermoplastic composition for the core layer in relation to the second thermoplastic polymers for each capstock layer was such that, after feedblock coextrusion of the three layers was complete, the core layer had a thickness of 5.5 mm and each capstock layer had a thickness of 250 microns.

example 3

[0027] In this example, as in Example 1, plastic sheet products containing one capstock layer bonded to the core layer were prepared. The first thermoplastic polymer used for the core layer and the second thermoplastic polymer used for the capstock layer were the same: a copolymer of about 94 wt. % methyl methacrylate and about 6 wt. % methyl acrylate having a melt index of 2.1, a weight average molecular weight of 150,000 and a refractive index of 1.490. The amount of the first thermoplastic composition for the core layer in relation to the second thermoplastic polymer for the capstock layer was such that, after feedblock coextrusion of the two layers, the core layer had a thickness of of between about 2 and about 9 mm as reflected in Table 1, and the capstock layer had a thickness of between about 125 and 195 microns as reflected in Table 1. Particles comprising beads of a crosslinked polymethyl methacrylate with a refractive index of about 1.52 and average particle diameters of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com