Plasma display panel

a technology of display panel and plasma, which is applied in the manufacture of electrode systems, electric discharge tubes/lamps, gas discharge sealing, etc., can solve the problems of deteriorating the quality of display operation, low noise level at audible frequency, and abnormal noise, so as to prevent the generation of noise due to malcontact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be explained more in detail with reference to embodiments and drawings.

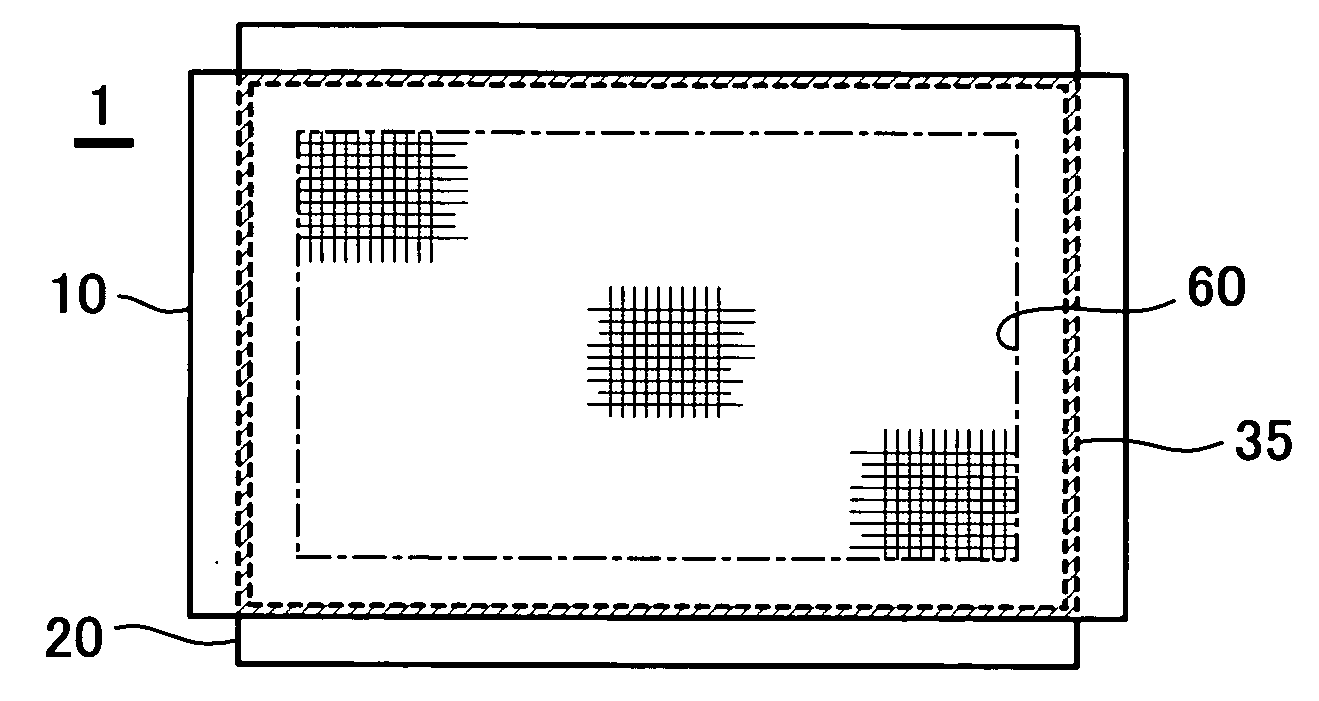

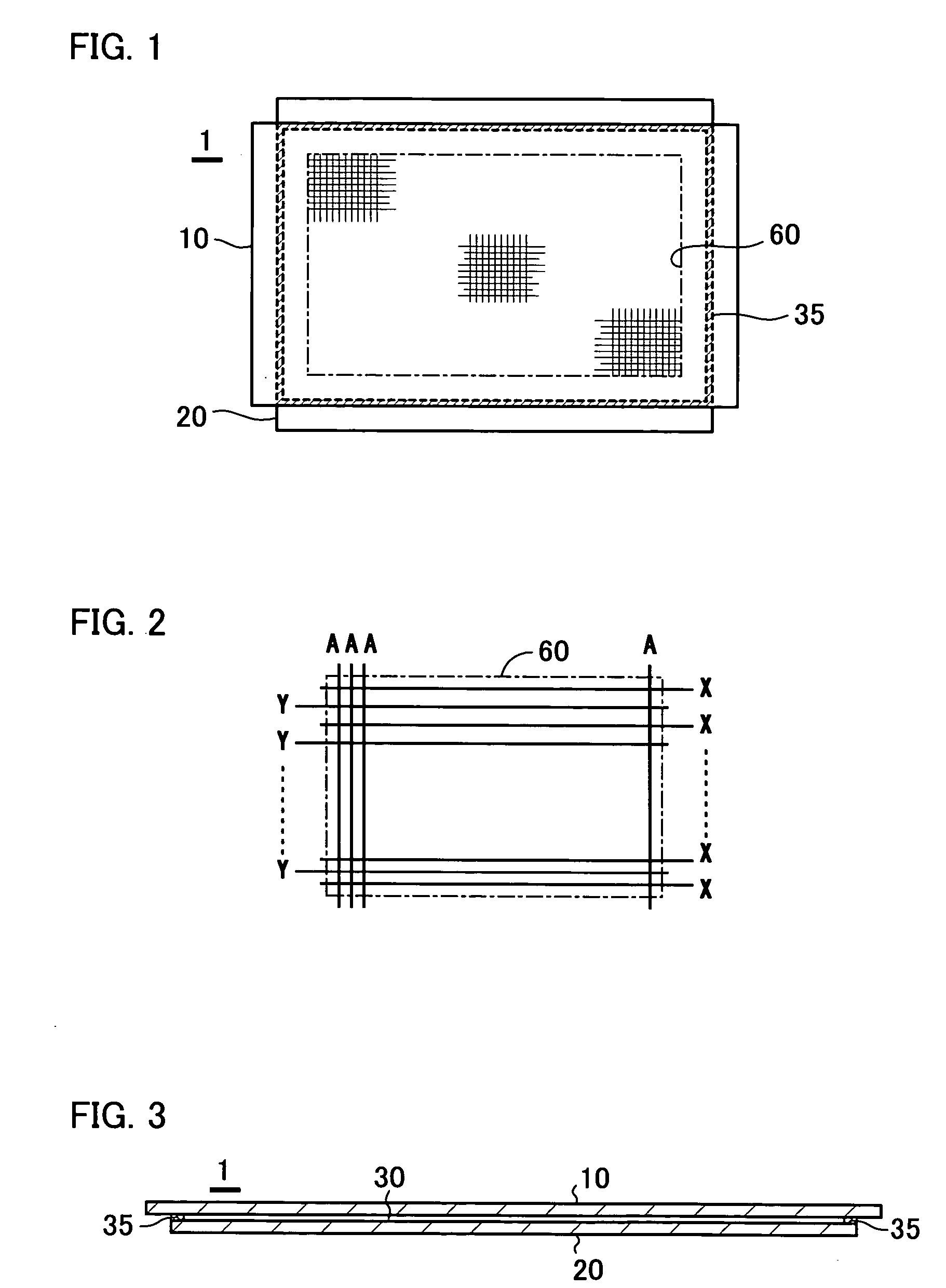

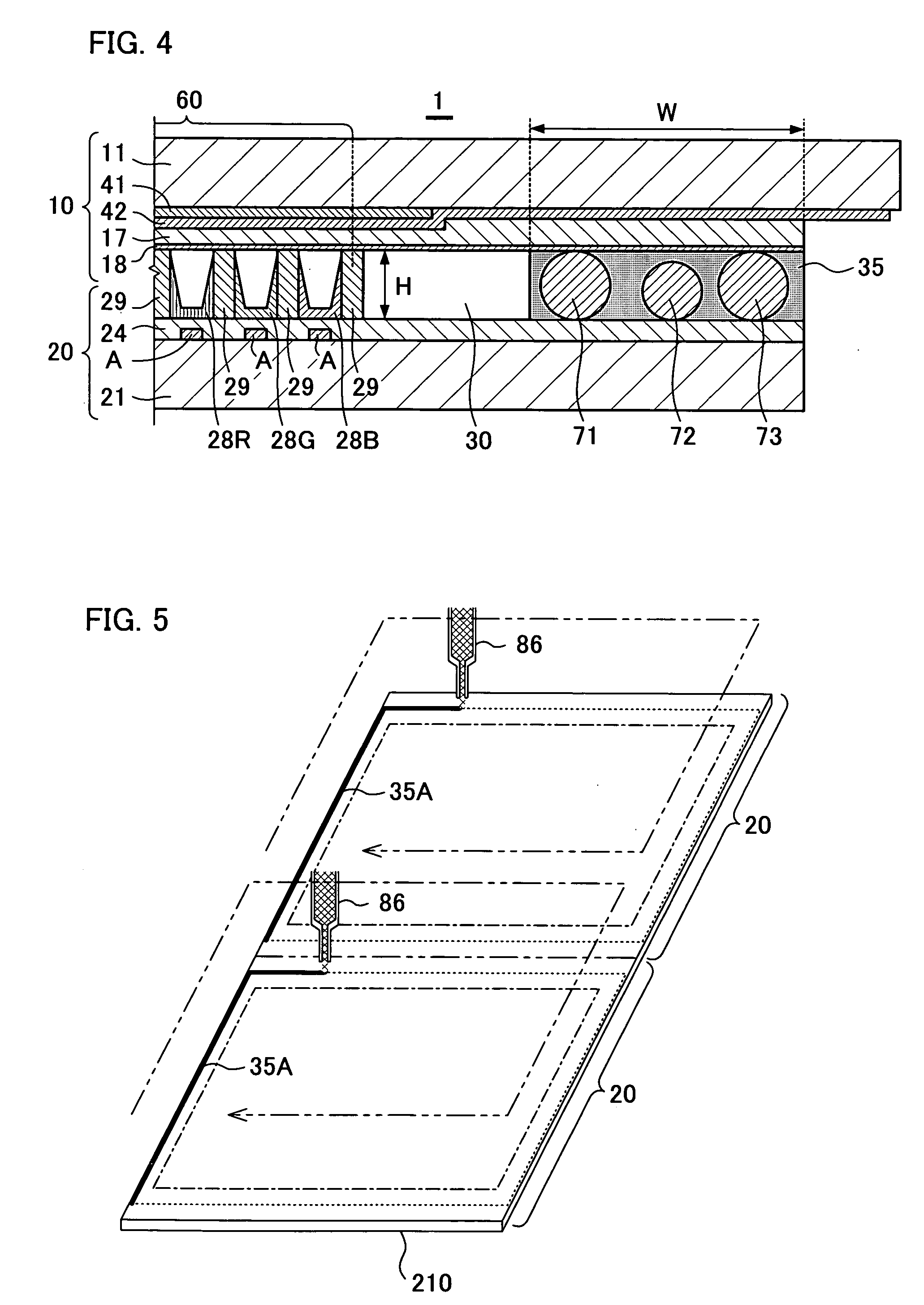

[0025]FIG. 1 shows a general structure of a plasma display panel. The plasma display panel 1 includes a front substrate 10 and a rear substrate 20, which constitutes a screen 60 made of plural discharge cells arranged in a matrix. Each of the front substrate 10 and the rear substrate 20 has a structural body including a glass substrate that is larger than the screen 60 and has a thickness of approximately 3 millimeters, on which electrodes and other elements are arranged. The front substrate 10 and the rear substrate 20 are overlapped so as to be opposed to each other and are sealed at their peripheral portions surrounding their overlapped portions by using a sealing material 35 that has a frame-like shape in a plan view. As shown in FIG. 1, the front substrate 10 extends from right and left sides of the rear substrate 20 by approximately 5 millimeters, while the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com