Process for coating modified bitumen membranes using reflective laminate coatings

a technology of reflective laminate coating and modified bitumen, which is applied in the direction of paper/cardboard containers, instruments, transportation and packaging, etc., can solve the problems of major maintenance expenditures of owners, difficult coating of granules, and coating problems in maintaining roof surface reflectivity, etc., to achieve greater strength and adhesion to the roofing membrane, the effect of reducing maintenance expenditures and ensuring the effect of adhesion

Inactive Publication Date: 2005-11-24

BUILDING MATERIALS INVESTMENT

View PDF35 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

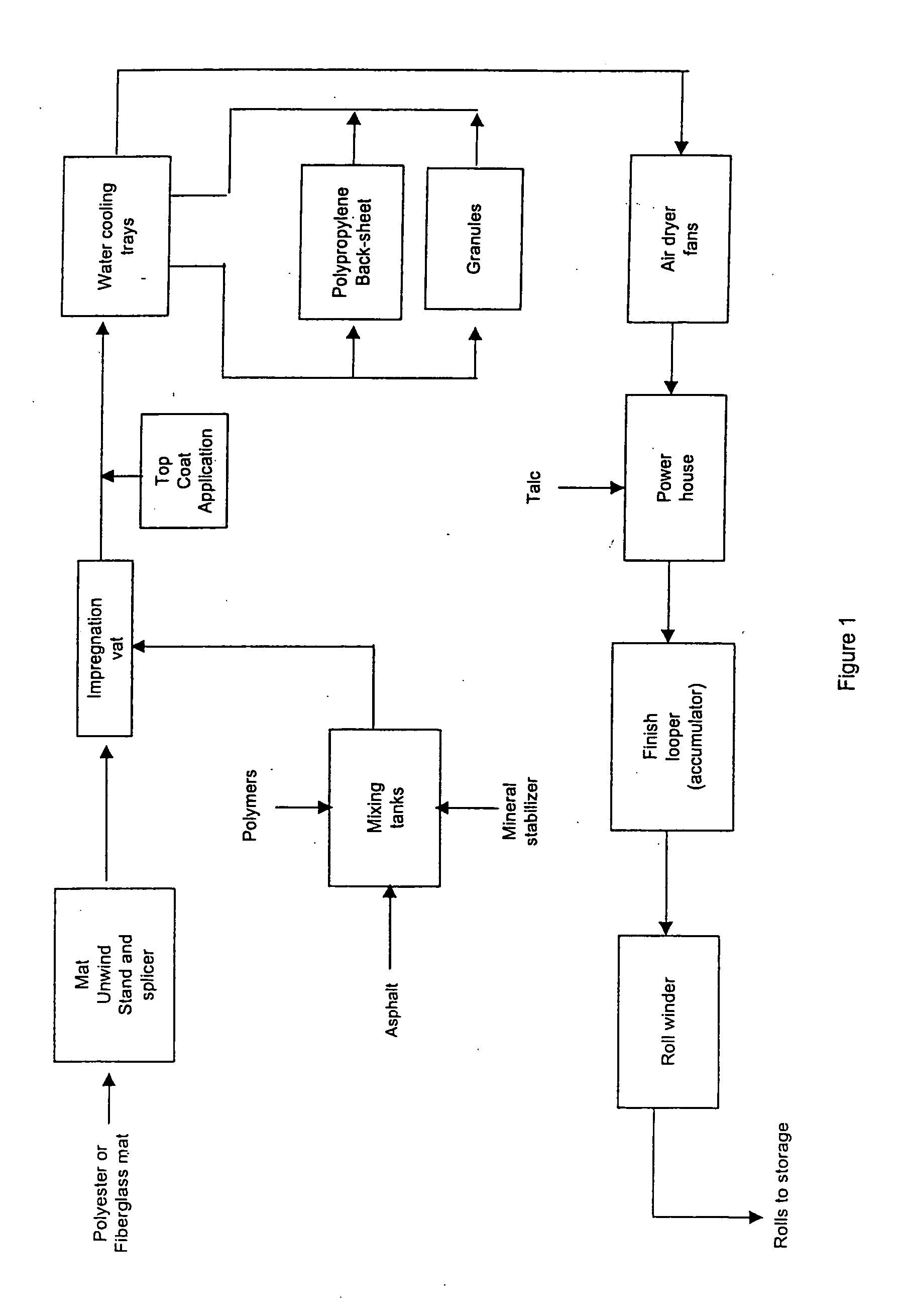

The present invention provides an improved laminate composition for use in roofing products that provides energy efficacy, greater reflectivity, greater adherence, and a method of manufacture whereby the coating is applied during manufacture of the roll roofing membranes. The reflectivity provided by the inventive laminate composition, meets today's Energy Star® standards. The roofing product produced is flexible enough to allow the product to be rolled without cracking, yet is sufficient puncture and scuff resistant to adequately protect the laminate. The laminate is a white reflective laminate that adheres well to various roof substrates, particularly modified bitumen membranes. The method of the present invention involves applying the laminate that is adhered to roofing membranes during the manufacture of the roof membrane obtained via the extrusion processes to the roll roofing membrane while it is still hot exiting the formation line where it is produced, resulting in heat activated curing and adhesion to the membrane. The resulting coated roof has greater reflectivity than that achievable with coatings applied subsequent to placement of the membranes on site. The energy efficacy of the laminate is determined by its solar reflectance. The laminate composition of the present invention comprises a dispersion of plastic resins and a pigment. The invention is also related to the film, i.e. top coat, that is formed from the top coating composition of the present invention as well as roofing products that are coated with the same. The laminate is applied in-plant during manufacture of the roll roofing membranes in order to achieve a higher reflectivity.

Problems solved by technology

With prior art white reflective coatings problems have occurred in maintaining roof surface reflectivity.

Depending on the geographic exposure and how well roof surfaces drain, keeping roof surfaces white and preventing premature failure from cracking and peeling can be a significant challenge and result in major maintenance expenditures for owners.

However, granules are difficult to coat because of their rough, uneven surface areas.

Moisture and air pockets can be trapped under the coating and lead to blisters or pinholes in the cured coating.

Inconsistent coverage and potential cracking of areas where the coating is applied too heavily are additional problems related to application of previous coatings.

Virtually all parts of North America have some application limitations as a result of cold weather, daily rainstorms, high humidity and / or fog, or reduced daylight hours during winter.

Rain on an uncured coating will cause a partial or total coating run-off.

Problems occur when an acrylic coating is specified on a construction project without regard to the time of year the coating is to be installed.

Cold temperatures and lack of sunlight decrease the freshly applied coating's evaporation.

This often requires cleaning of the surface and reapplication of the coating.

Wet weather and cooler temperatures inhibit final cure and may inhibit proper fusing.

Consequently, acrylic coating applications cannot be attempted on roofing projects from late fall to early spring in most North American areas.

Film laminate coatings cannot be directly applied to asphaltic compounds because of inter alia difficulties due to heat sensitivities of the film, potential for delamination of the film caused by exudation of oil from modified bitumen membranes, and discoloration of the film due to exudation of oil.

However, foil materials typically have very smooth surfaces, which may provide insufficient surface area for binding, and therefore could delaminate from the surface of the asphaltic compound after cooling of the roofing membrane.

Moreover, use of a thin layer of aluminum can cause the surface film laminate to fail by erosion or damage due to traffic.

Conversely, use of a thicker foil increases cost in addition to posing other problems such as the product becomes very rigid and difficult to handle.

Importantly, foil will not meet Energy Star® requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0087] The asphalt is heated to approximately 400° F. Polymer is added and high shear mixed. Fillers are added under low shear. The asphalt compound thus made undergoes Quality Control approval. It is then pumped to the production line. The asphalt compound is saturated in reinforcement. The film laminate is adhered at approximately 230° F. The combination is cooled under water, dried and rolled up in 100 square feet.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Login to View More

Abstract

A method of applying a laminate composition containing a whitening pigment during manufacture of modified bitumen roll roofing membranes, is provided. The laminate composition is heat activated providing greater adherence to surfaces that it applied to, and greater reflective properties. The laminate has an initial energy efficiency rating greater than or equal to 0.65 for a low-sloped roof, or an initial energy efficiency greater than or equal to 0.25 for a steep-sloped roof.

Description

[0001] The present invention relates to a new and useful laminate composition and a method for applying the laminate, and more specifically, to a reflective laminate film composition for roll roofing products that is applied during the manufacturing process. BACKGROUND OF THE INVENTION [0002] Modified bitumens were developed in Europe during the late 1960's for roofing applications and found a market in the United States during the 1980's. These products are an important part of the roofing industry and are produced as a continuous sheet on a roofing line and are later cut down to individual pieces and wound in rolls of various lengths. Subsequent to laying on a roof, they are top coated with coatings that provide energy efficacy and reflectivity. [0003] With prior art white reflective coatings problems have occurred in maintaining roof surface reflectivity. Reflectivity decreases the most during the first year of a roof's life. After three years, the rate that reflectivity declines...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): B32B3/00B32B11/00B32B33/00E04D5/10

CPCB32B11/00B32B33/00B32B37/153B32B2307/416B32B2395/00Y10T428/24372E04D5/10Y10T156/10Y10T428/24355Y10T428/25B32B2419/06Y10T428/31855Y10T428/31931Y10T428/31938Y10T428/31935B32B11/046

Inventor KHAN, AMIRSOUTO, MICHAEL DE

Owner BUILDING MATERIALS INVESTMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com