Foundation void former unit

a former unit and foundation technology, applied in the direction of load-supporting elements, structural elements, building components, etc., can solve the problems of cumbersome and time-consuming exercise, and achieve the effect of enhancing the strength and support function of the uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

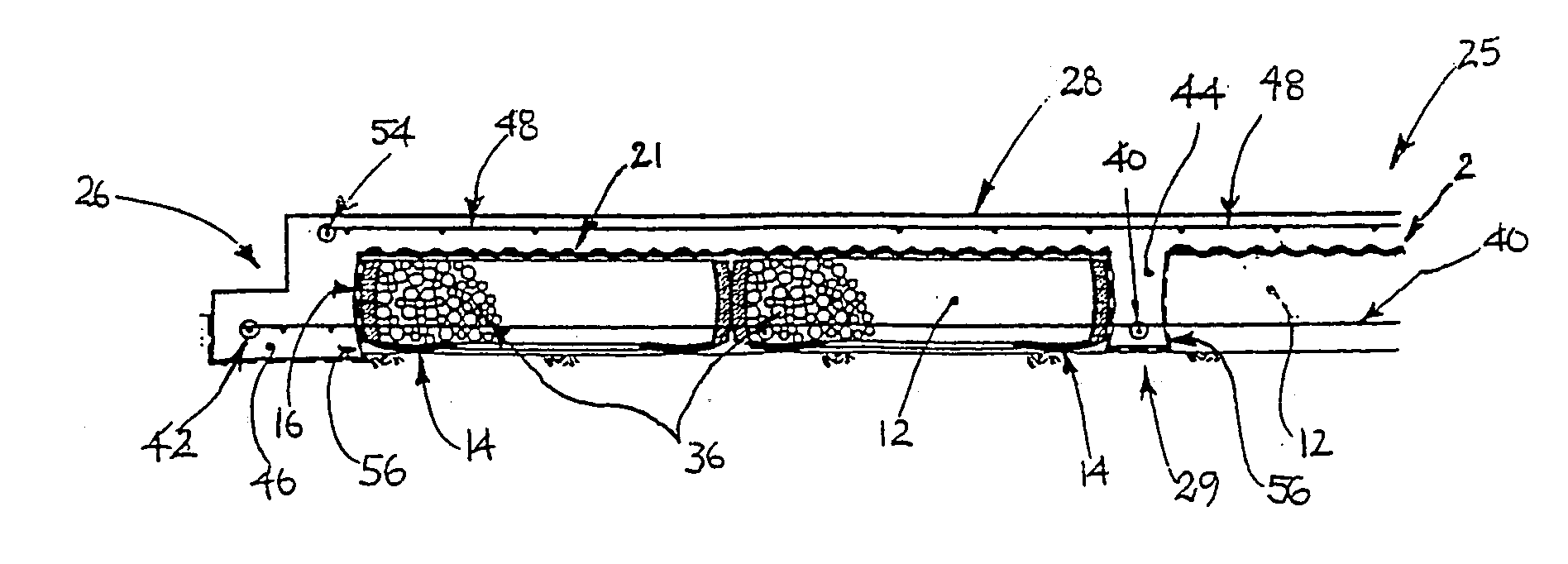

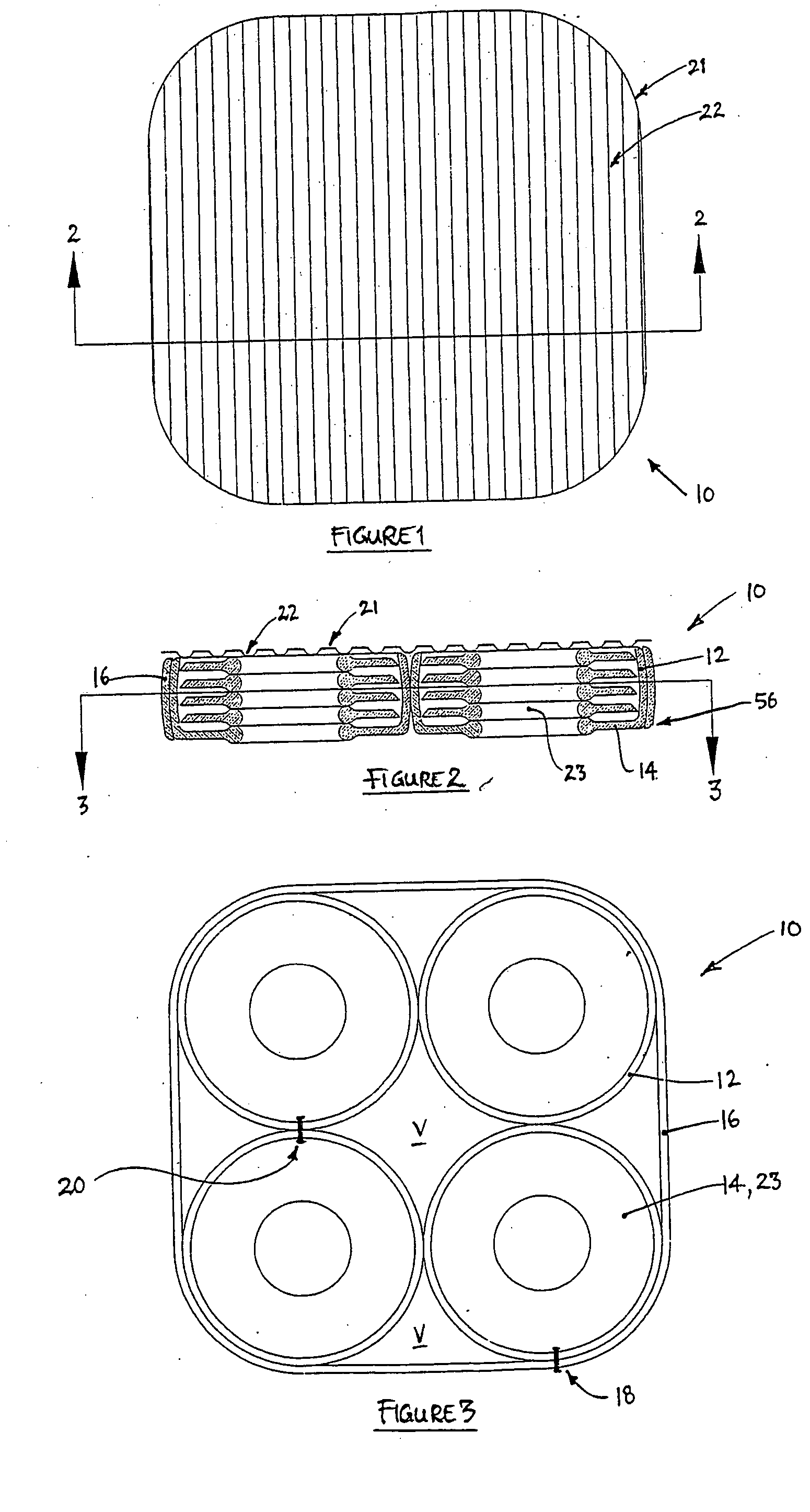

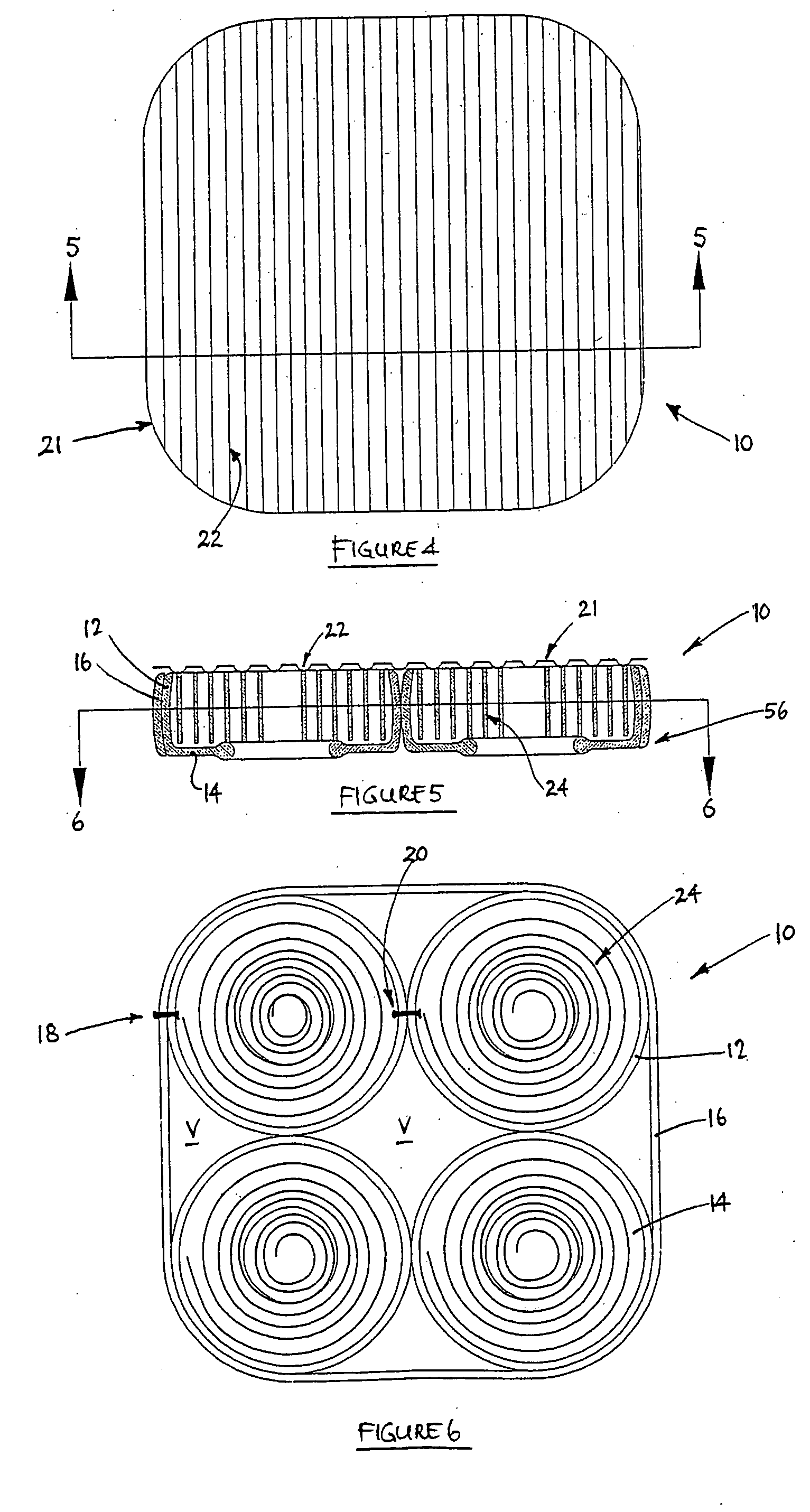

[0061] Referring firstly to FIGS. 1 to 6, a void former lo in accordance with the present invention includes a plurality of, in this case four, tyres 12. Each tyre preferably has an in-use upper tyre side wall removed therefrom (as best seen in FIGS. 2 and 5) and has an in-use lower side wall 14 remaining intact. A retention element in the form of one or more lengths of tyre tread 16 or conveyor belt 16 extends around the perimeter of the four tyres as shown, and is attached thereto via a plurality of fastening elements in the form of screws (e.g. Tec Screws), bolts or pins 18 (one such screw / bolt / pin being shown in FIGS. 3 and 5). Alternatively or additionally industrial strength adhesive may be used. In addition, each tyre is attached to each adjacent tyre, at adjacent treads, by screws, bolts or pins 20 (one such screw / bolt / pin being shown in FIGS. 3 and 5).

[0062] A continuous but discrete capping in the form of lid or cap 21 is shown positioned on the void former 10, and is typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com