Method for improving well quality

a well quality and well technology, applied in the field of wells, can solve the problems of contaminated oil coming from oil wells, general undesirable contaminants, etc., and achieve the effects of improving the quality of liquid, increasing the amount of cleaner liquid, and increasing the level of radionuclides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

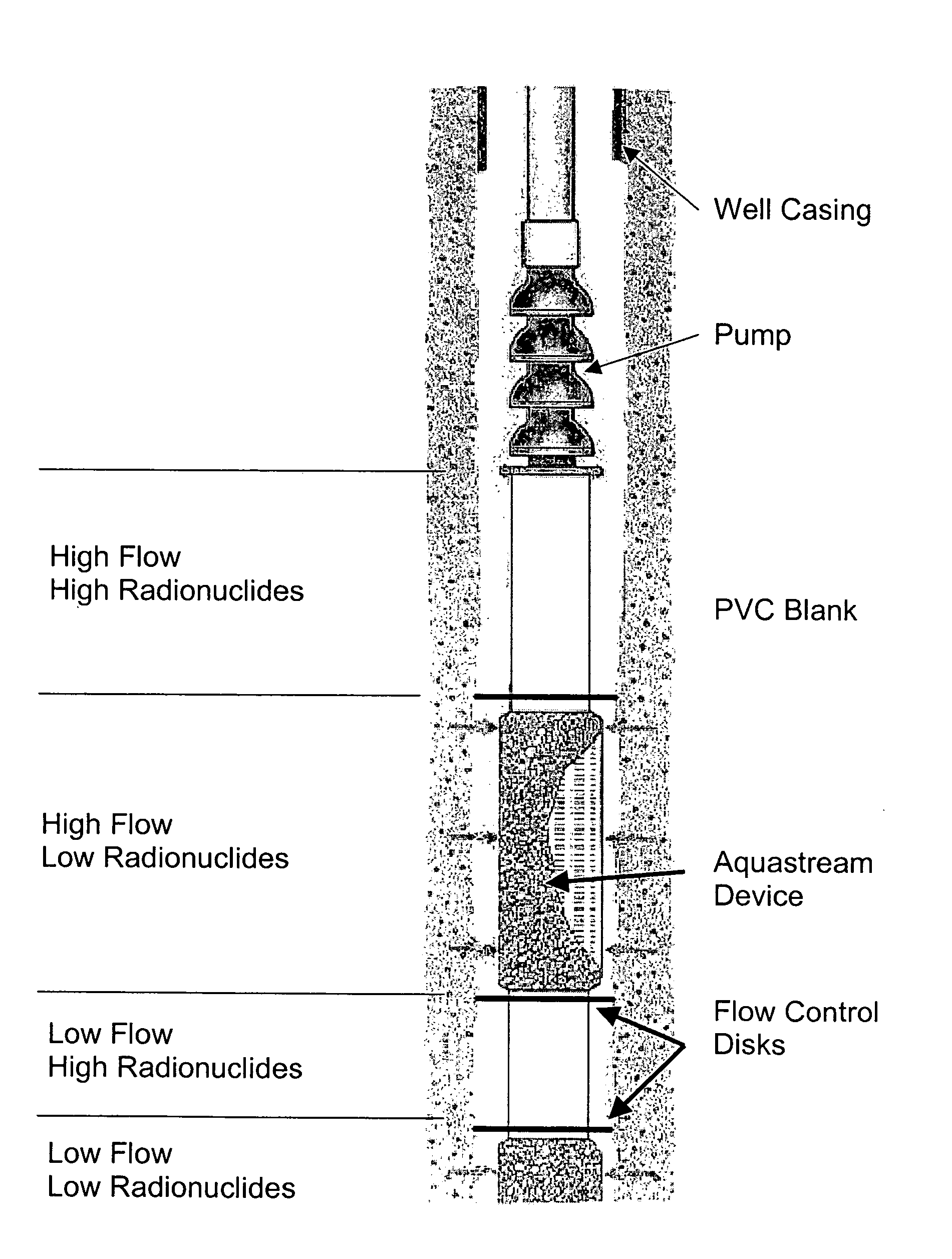

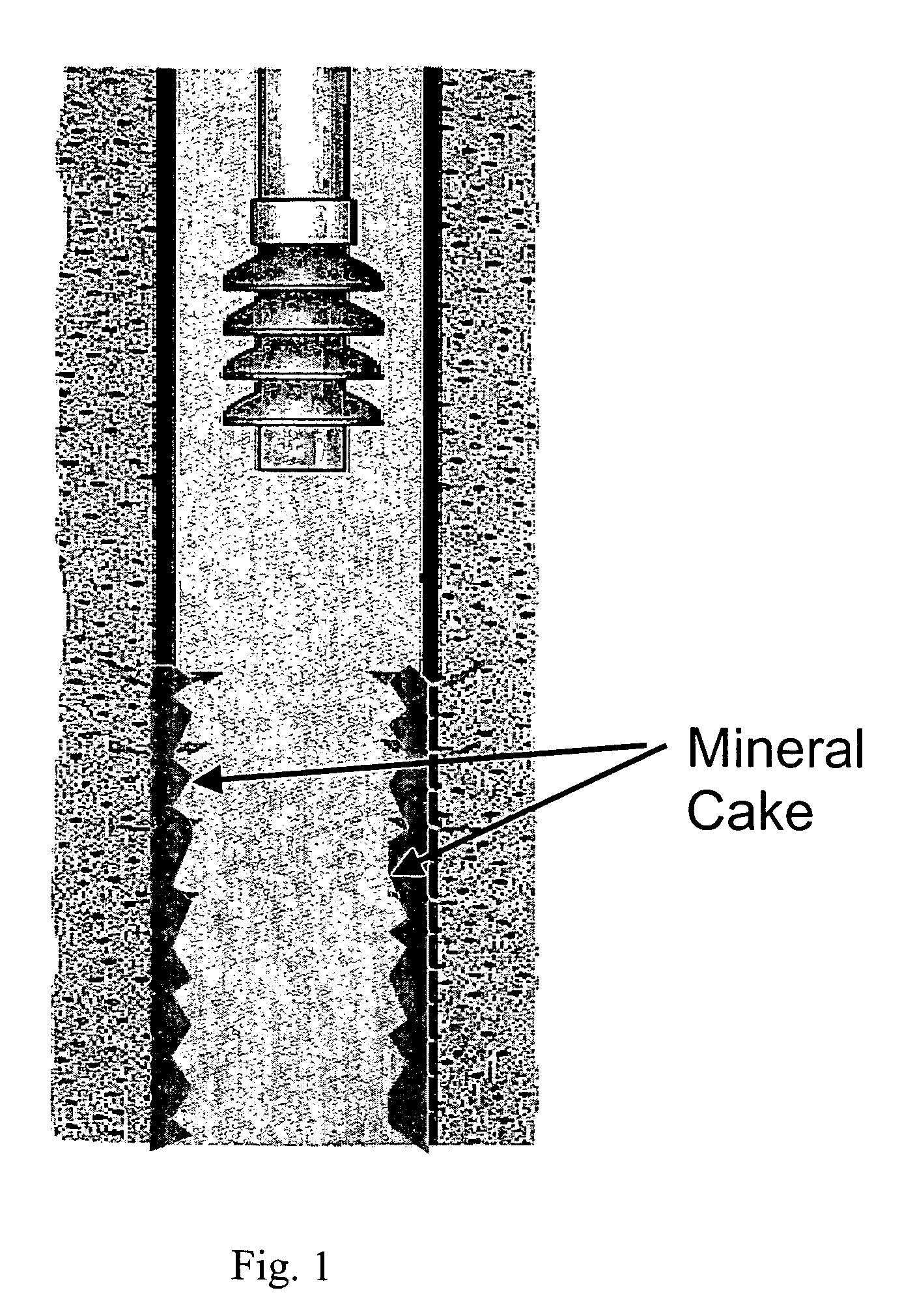

[0015]FIGS. 1-4 illustrate one embodiment of the present invention as used in connection with the treatment of a water well for purposes of reducing the level of radionuclides in water pump from the well. Of course, it should be understood that other contaminants could be removed using the same of similar process. The illustrated embodiment utilizes a two-phase process to reduce contamination of water pumped from a water well.

[0016] Phase I includes gathering data regarding historical well performance, sampling and logging the characteristics of water from different sections of the well, and cleaning the well. Data gathering involves collecting and reviewing historic data about the well. This data includes hydraulic, water chemistry, and geologic information. In the event that recent data is not available at different flow rates, this data can be collected prior to removing the pump. The primary purpose of this step in the process is to provide a base line against which future data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com