Tissue products having substantially equal machine direction and cross-machine direction mechanical properties

a technology of machine direction and mechanical properties, applied in the field of tissue products, can solve the problems of product failure, strength alone ignore, etc., and achieve the effects of good stretch, improved in-use strength, and good stretch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Hypothetical

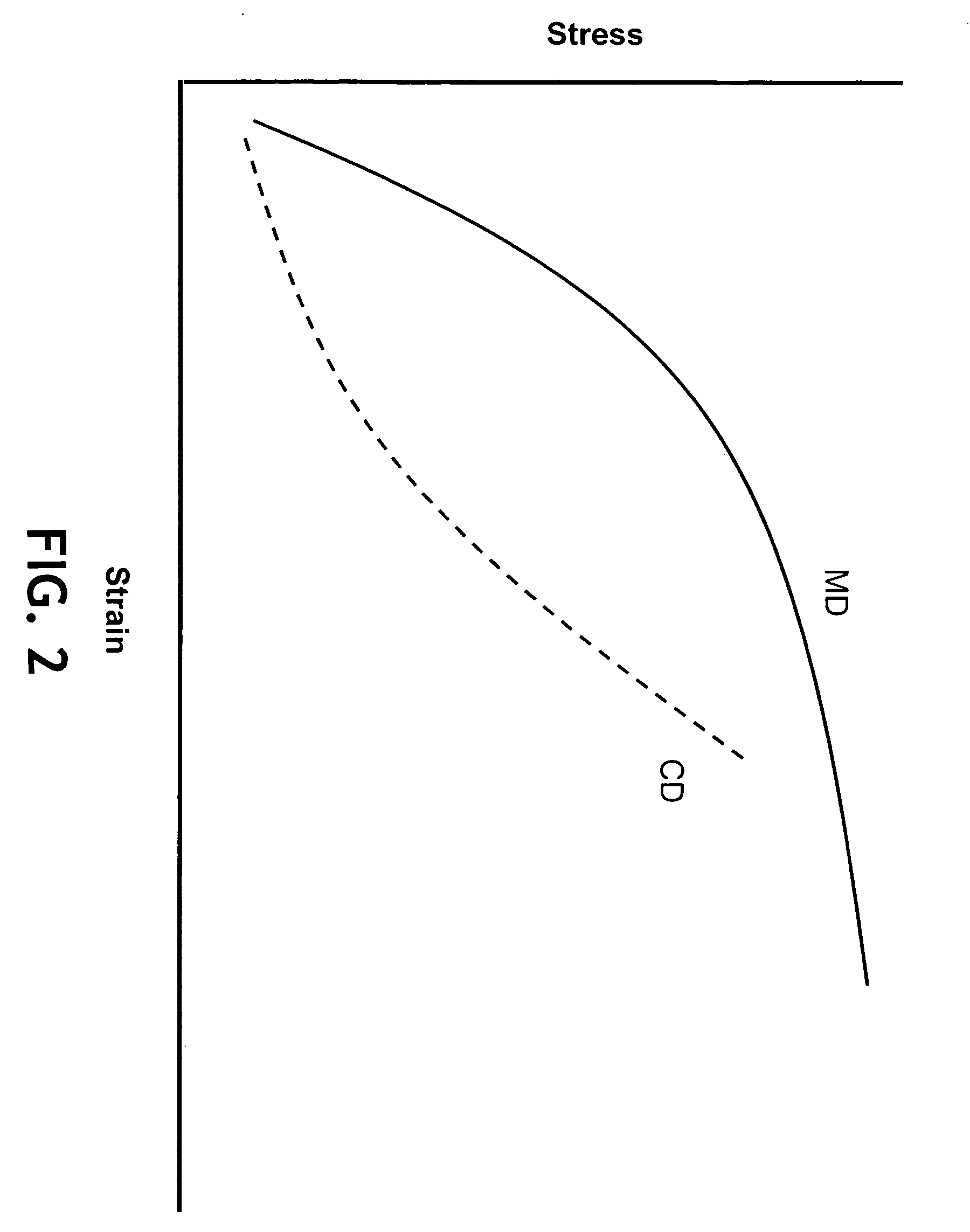

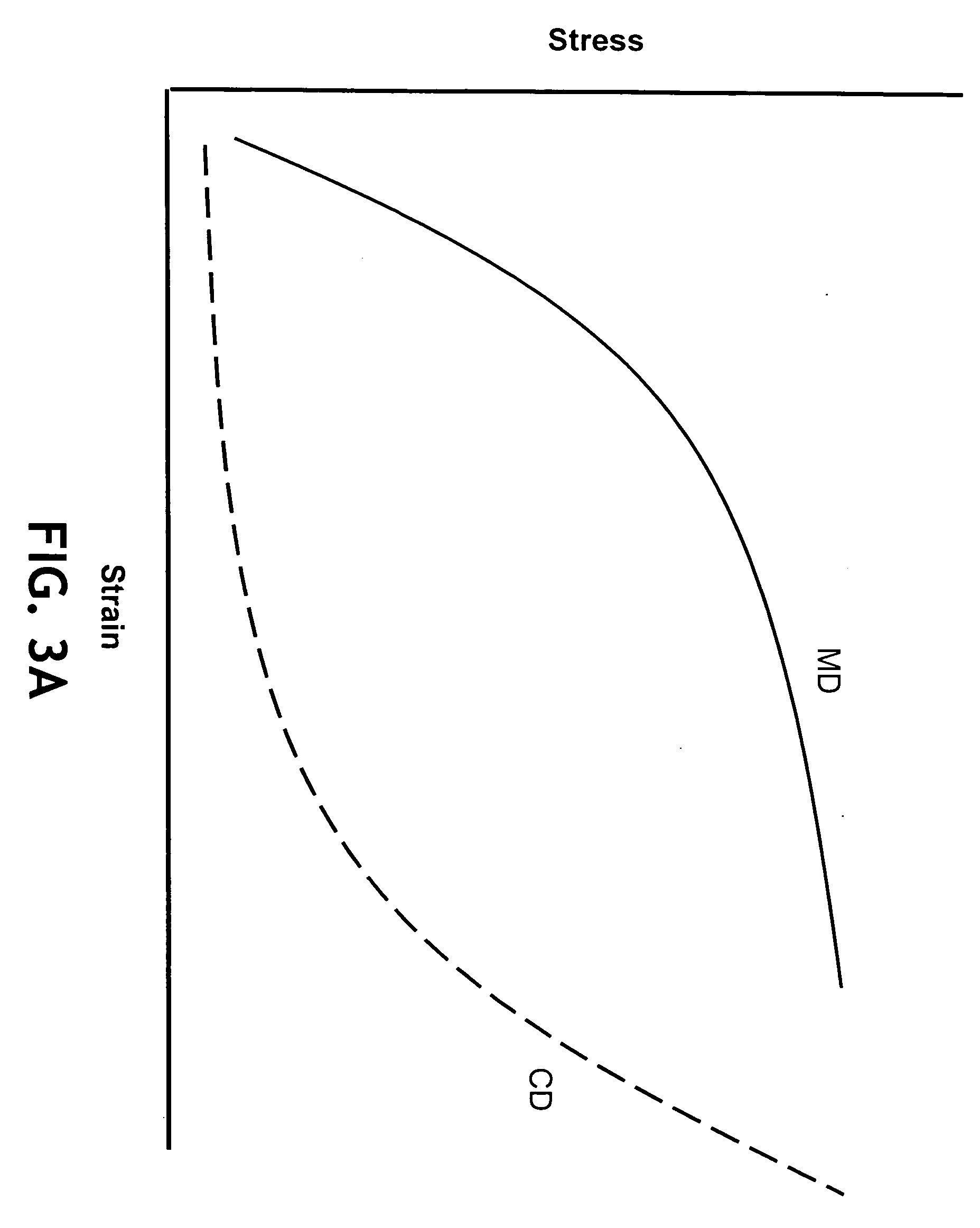

[0047] The need for significant stretch (about 5 percent or greater) is an important factor for purposes of this invention because it is relatively easy to remove stretch and lower tensile strength in the MD to make those properties equal to the stretch and tensile strength in the CD, thereby resulting in an equal or substantially equal MD TEA and CD TEA. However, since stretch and strength are much more difficult to generate in the CD, merely making these properties equal would only provide a weak sheet with low stretch with little or no consumer benefit. To illustrate this point, hypothetical products are listed in Table 1 below showing the effect of their properties on TEA.

TABLE 1MDCDMDTensileTensileStretchCDMD TEACD TEAProductg / 3″g / 3″%Stretch %g-cm / cm2g-cm / cm2A10008001559.82.6B800800552.62.6C80080010105.25.2

[0048] The hypothetical examples are assumed to have a linear stress-strain curve which is not usually the case for tissue products, which have stress-strain c...

examples 2-42

[0050] To further illustrate the invention, a pilot uncreped throughdried tissue machine was configured similarly to that illustrated in the aforementioned Rugowski et al. patent and was used to produce a one-ply, uncreped throughdried bath tissue basesheet. More specifically, 100 pounds of bleached northern softwood kraft fiber were dispersed in a pulper for 30 minutes at a consistency of 3 percent. Similarly, 100 pounds of bleached eucalyptus were dispersed in a pulper for 30 minutes at a consistency of 3 percent. The thick stock was then sent to a machine chest and diluted to a consistency of about 1 percent.

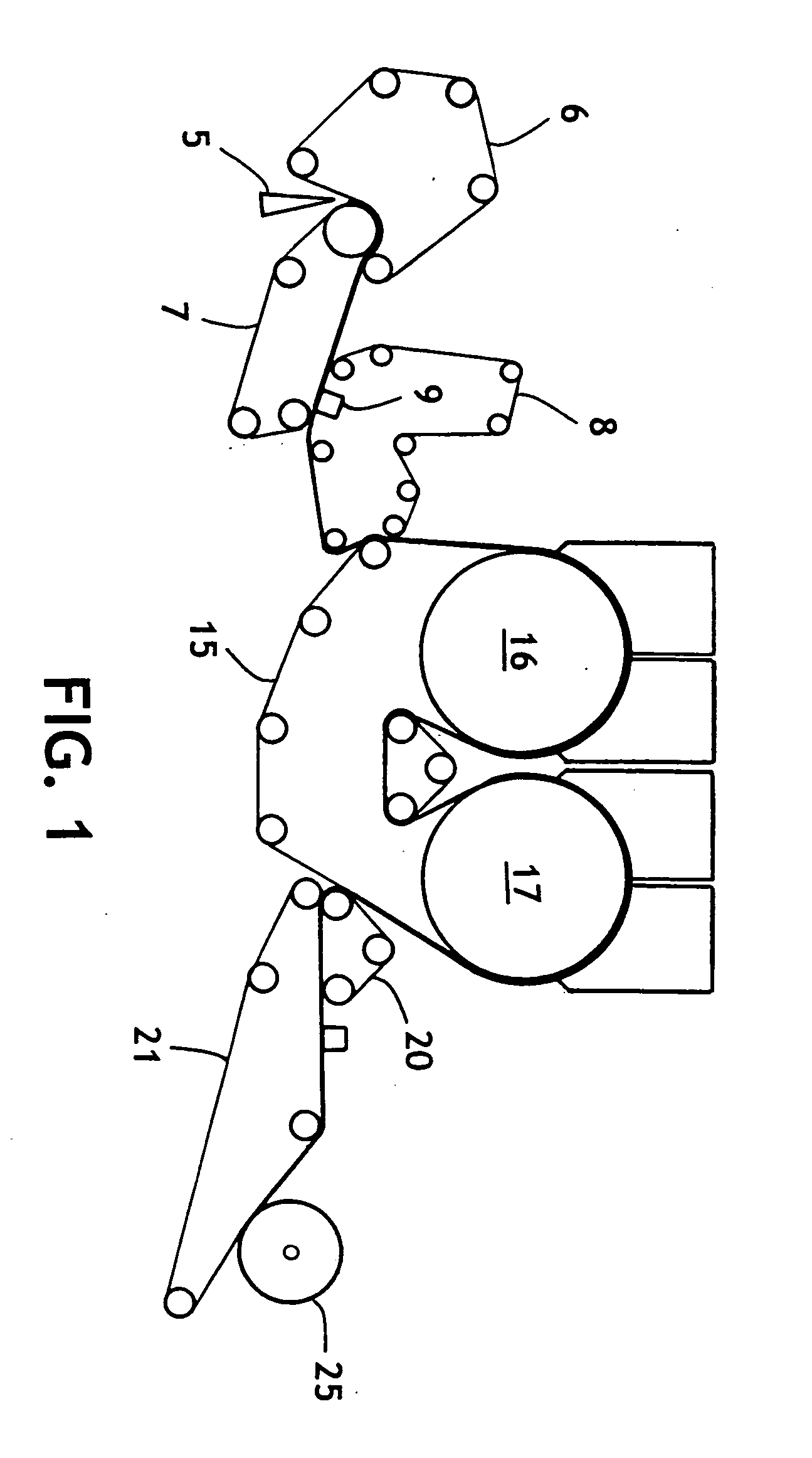

[0051] The machine chest furnish was diluted to approximately 0.1% consistency and delivered to a forming fabric using a three-layered headbox. The forming fabric speed was approximately 62 fpm. The resulting web was then transferred to a transfer fabric traveling at the same or slower than the forming fabric using a vacuum shoe to assist the transfer. At a second vacuum sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| equivalent circular diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com