PET copolymer composition with enhanced mechanical properties and stretch ratio, articles made therewith, and methods

a technology of mechanical properties and stretch ratio, applied in the field of preforms and their containers, can solve the problems of reducing wasting resources and energy, and difficulty in achieving source reduction, so as to improve the utilization rate of materials, improve shelf life, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

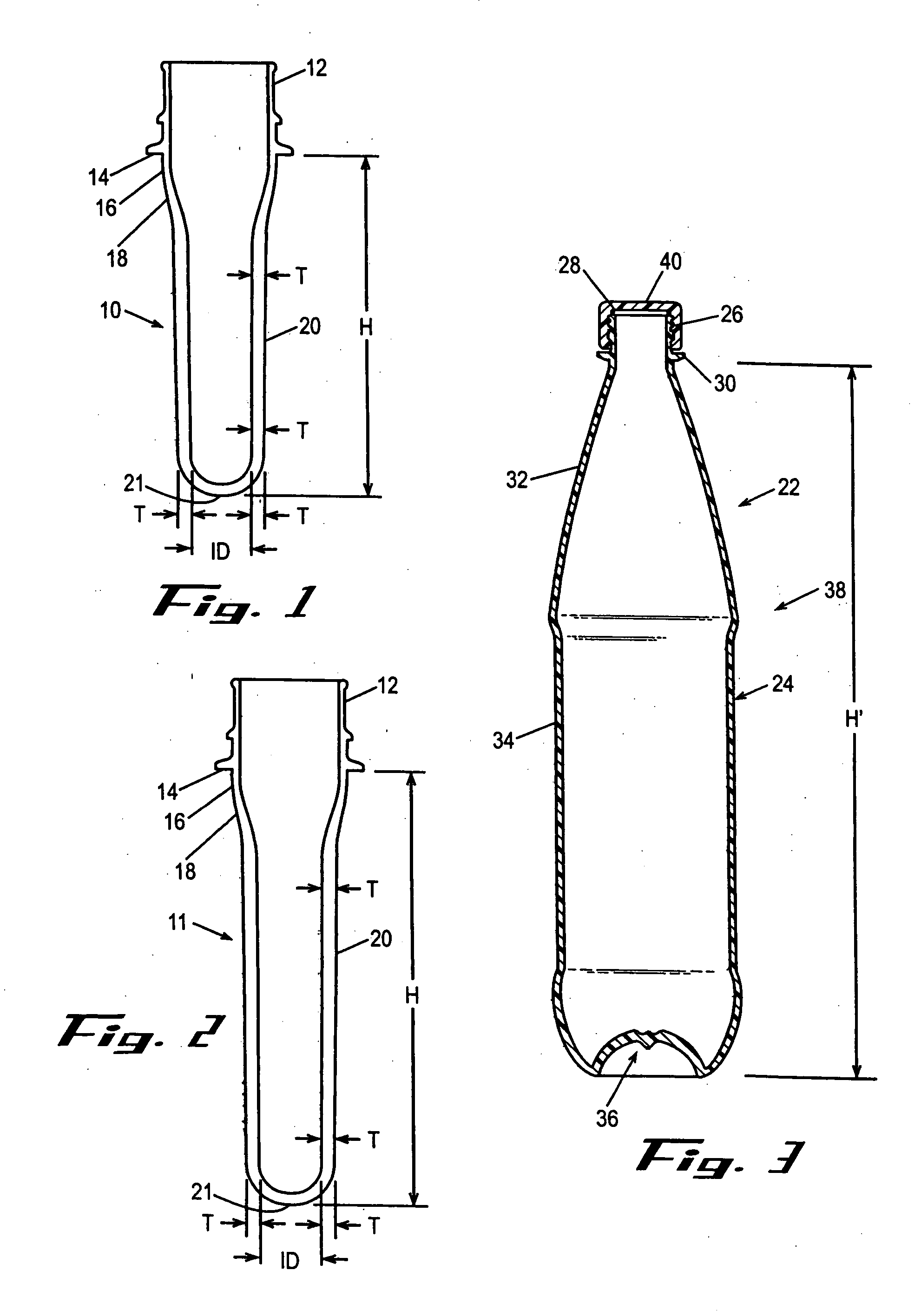

[0058] Different PET resins were injection molded with a lab-scale Arburg 75 unit cavity injection machine into conventional preform molds with a stretch ratio about 12.3 but with different gram weights. Resins were pre-dried to moisture levels below 30 parts per million (ppm). The preforms were then stretch blow molded with a SBO-1 stretch blow-molding machine into 500 ml Coca-Cola Contour bottles. A description of the weights and compositions of the samples is listed in Table 1. The #3 Samples are representative of embodiments of the present invention and the #1 and #2 Samples are comparative.

TABLE 1GramDEGNDCIPASampleweightmole %mole %mole %#1-27272.8903#2-27271.4502.5#3-27271.450.50#1-26262.8903#2-26261.4502.5#3-26261.450.50#1-24242.8903#2-24241.4502.5#3-24241.450.50

example 2

[0059] The containers produced in Example 1 were subjected to a standard thermal stability test, which involves filling the containers with carbonated water, holding them at 22 deg C. for 24 hours, subjecting them to a temperature of 38 deg C. for an additional 24 hours, and then measuring the dimensional changes that occurred relative to the unfilled containers. The data in Table 2 shows that low DEG, low NDC PET Copolymers of the #3 Samples from Example 1 have increased thermal stability property for pressurized containers over that of the comparable Samples #1 and #2, as evidenced by lower thermal expansion results. The 24 gram Sample #3 exhibits enhanced thermal stability compared to the 27 gram Sample #1 control.

TABLE 2Label DiameterPinch DiameterSampleExpansion (%)Expansion (%)#1-273.15.4#2-272.65.6#3-272.34.8#1-263.25.4#2-263.97.5#3-262.75.4#1-243.65.8#2-242.44.9#3-242.64.7

example 3

[0060] In Example 3, containers made in Example 1 were tested for sidewall rigidity using a sidewall deflection test. The sidewall deflection test is designed to measure the amount of force required to deflect the label panel of PET bottles 12 mm (0.47″) with an 8 mm (0.32″) round tip probe at a cross-head speed of 508 mm / min. This measurement gives information about the rigidity of the container. The greater the force required to achieve a specific sidewall deflection, the greater the rigidity of the bottle sidewall.

[0061] The data in Table 3 shows that the low DEG, low NDC PET Copolymers of the #3 Samples from Example 1 have increased sidewall rigidity over that of the comparable Samples #1 and #2. The sidewall rigidity of the 24 gram sample #3 is equivalent to 27 gram sample #1 control.

TABLE 3SidewallDeflectionSample(Kgf.)#1-274.87#3-275.36#2-275.35#1-264.25#3-264.67#2-264.53#1-244.14#3-244.80#2-244.50

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com