System and method for product display, arrangement and rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Display Base and Pull Straps for Grocery Display

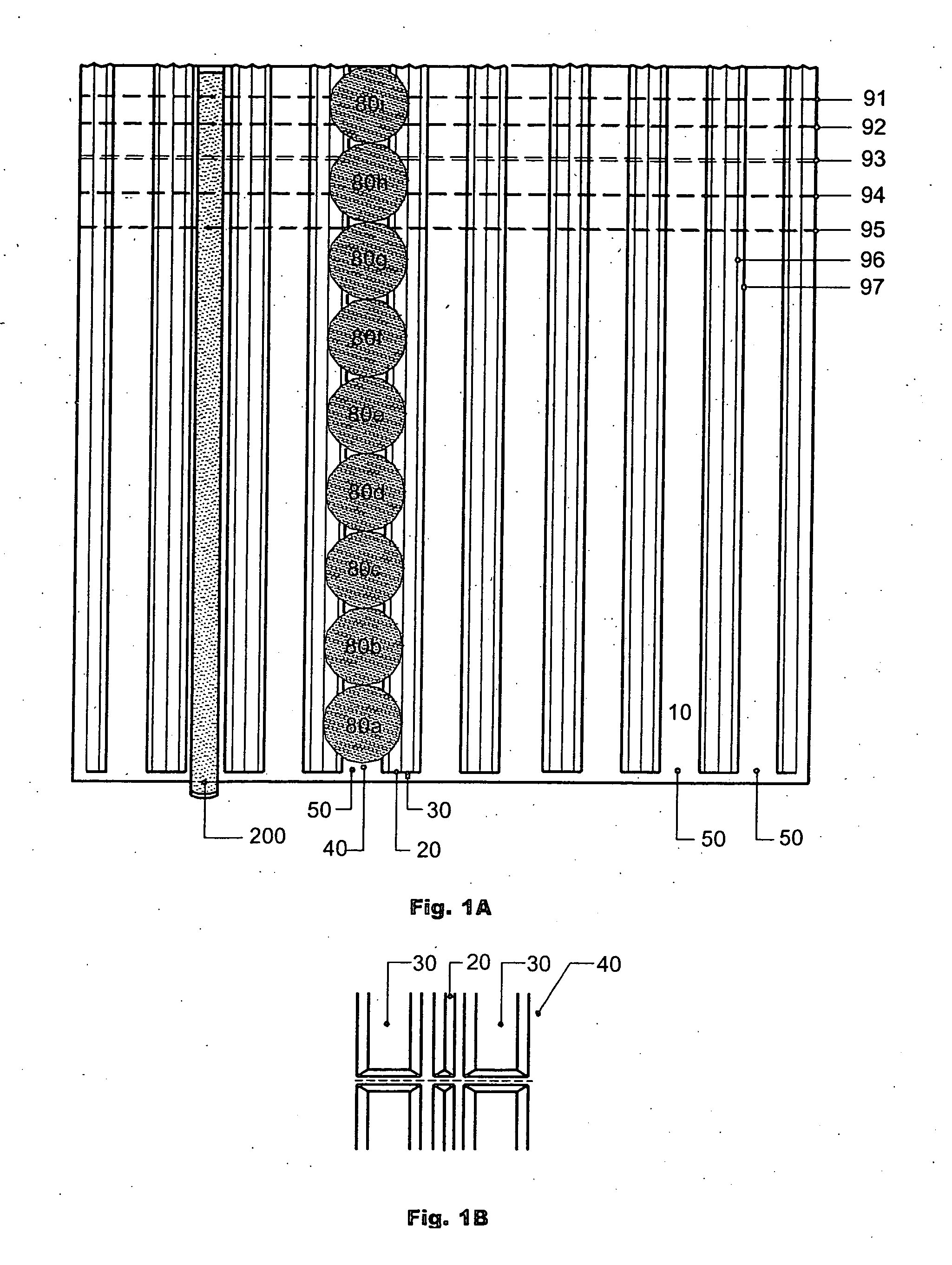

[0074] Referring now to FIG. 1A which is a top view of an embodiment of the current invention, several containers 80a-80i, such as soup cans are placed in one row 50 of a display base 10. Alternate embodiments support other sizes of cans, boxes, bags, and loose merchandise.

[0075] In this embodiment, the base may be a plastic sheet which may be bent or scored along one of several depth adjustment lines 91-97 at the rear of the base. This permits the base to be sized for standard grocery store shelve depths of 18, 19, 20, 21, 22, 23, or 24 inches. The rear of the base may be either bent up or may be bent and scored or cut to remove the excess material. The bending is typically performed by laying the base upside down and backwards on a shelf so that the base may be bent at an appropriate bend line. After bending, the extra base material may be left in a bent position or may be removed such as by cutting it off with a box blade.

[0076] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com