Apparatus for preventing motor overload of vacuum cleaner

a technology for vacuum cleaners and apparatuses, applied in the field of vacuum cleaners, can solve the problems of requiring an overly complex structure, and affecting the operation of vacuum cleaners, etc., and achieves the effects of reducing manufacturing costs, satisfying sealing, and reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. Throughout the description, the elements similar to, or identical with, those described in the background art as illustrated in FIGS. 1 and 2A-B will be identified by the same reference numerals and further detailed description of the structure and function thereof will rely on the description made above.

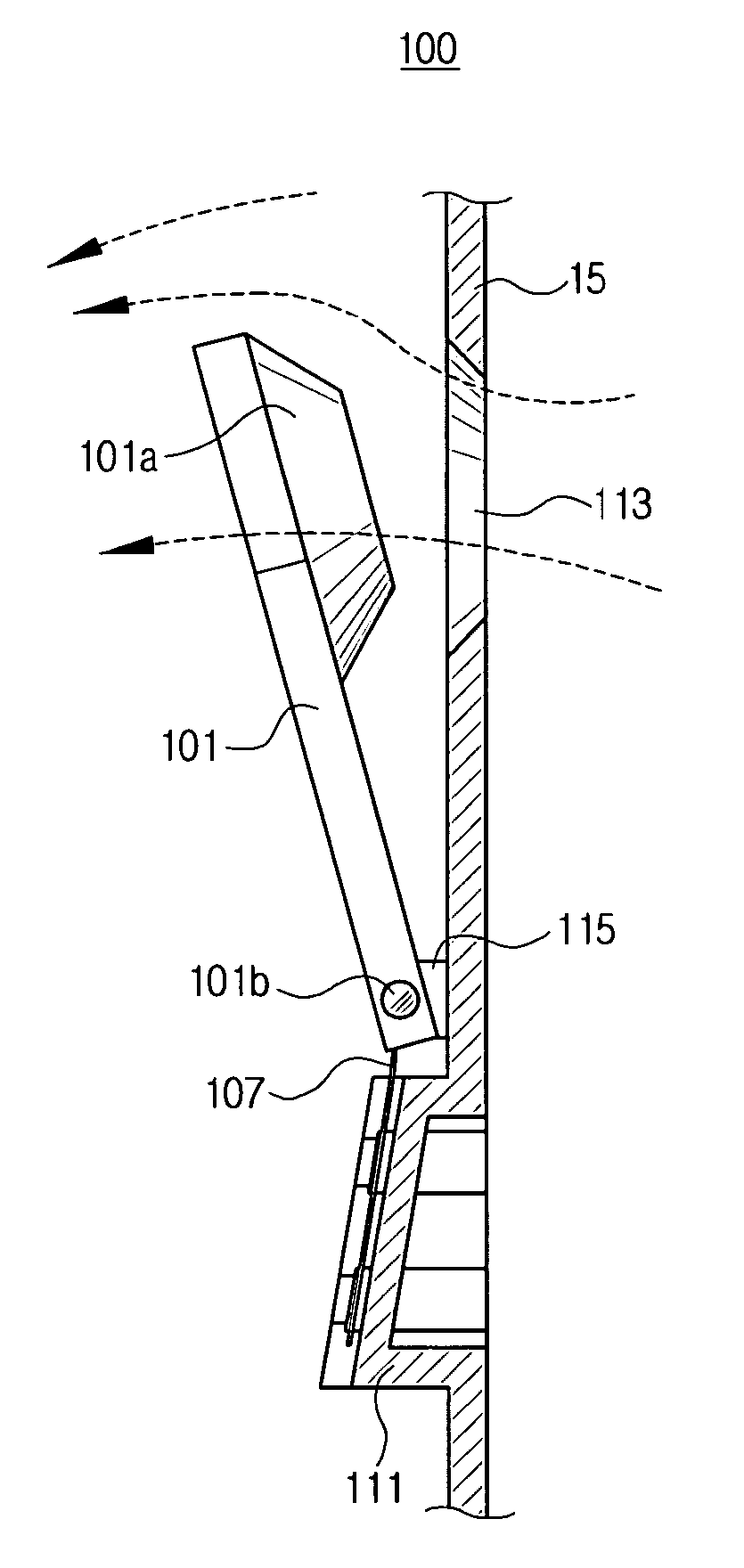

[0037] FIGS. 3A-C and 4A-B are views of a motor overload preventing apparatus for use in a vacuum cleaner according to a first preferred embodiment of the present invention.

[0038] Referring now to FIGS. 3 and 4, the first preferred embodiment of the motor overload preventing apparatus 100 includes a damper body 101 and a resilient member 107.

[0039] A tapered opening / closing portion 101a is formed in an end of the damper body 101, while the other end of the damper body 101 is connected to the partition 15 of the vacuum cleaner by a hinge, as shown. More specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com