Drilling apparatus, method, and system

a technology of rock bolts and drilling equipment, applied in drilling machines and methods, mining structures, cutting machines, etc., can solve the problems of noisy work environment, difficulty in obtaining accurate compressive strength measurements of rock in the field, disadvantages of rolling cone bits, etc., to improve the holding capacity of rock bolts, improve the geometry of rock bolt holes, and improve the pull-out capacity of support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

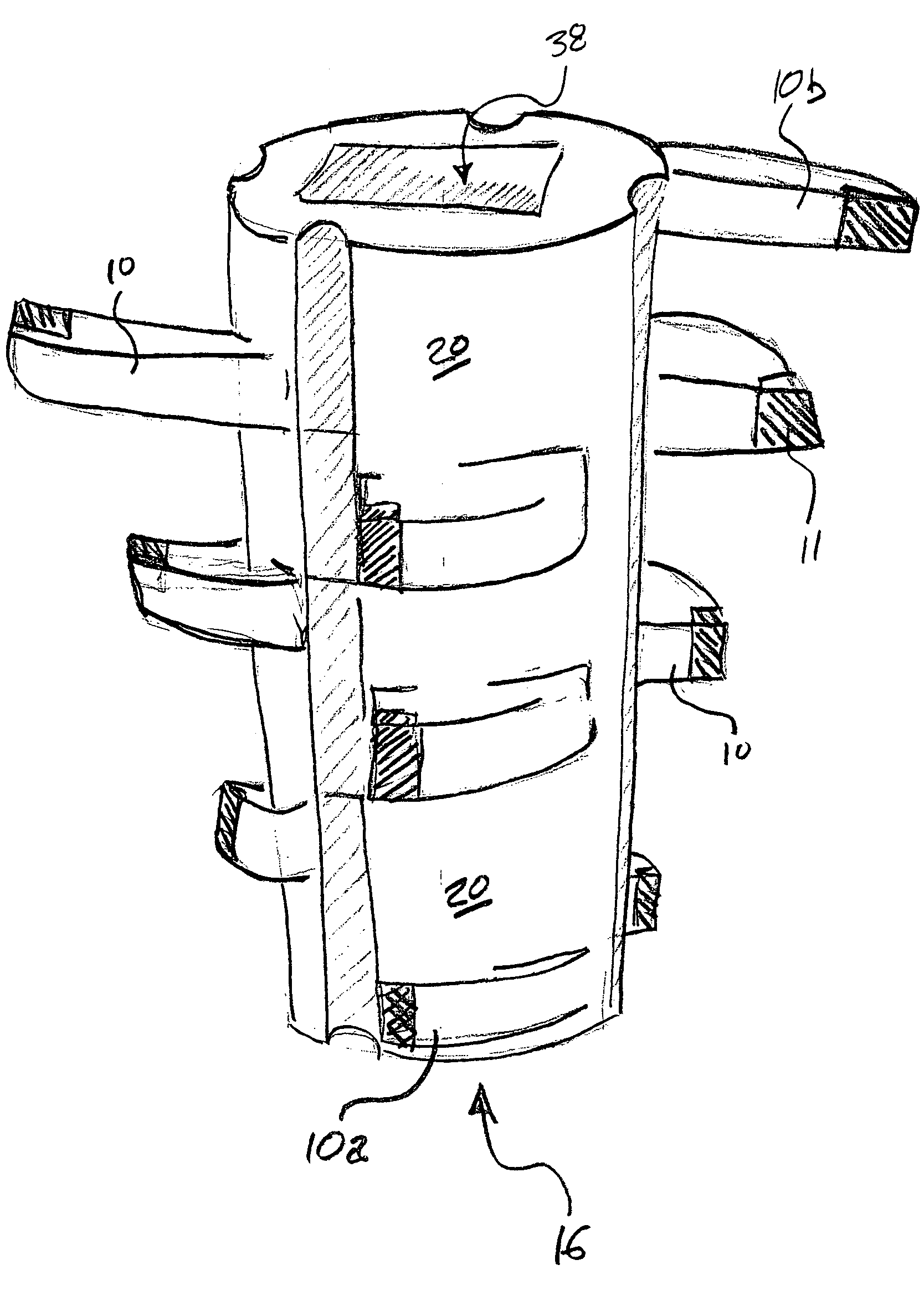

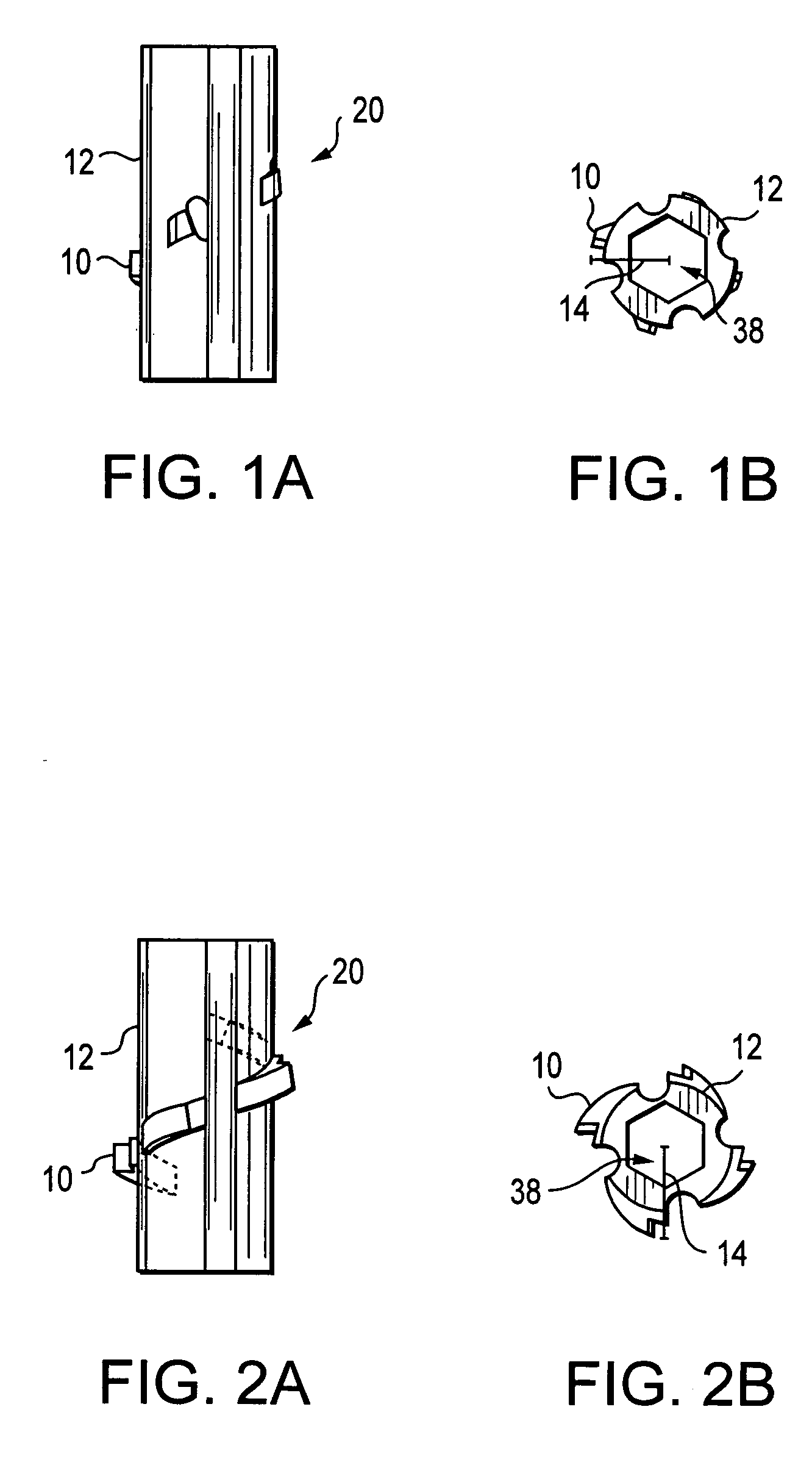

[0045] The invention relates to helical drag bits, systems incorporating the bits, and to methods of using the bits and systems. Throughout this detailed description, the terms “helical drag bit” and “helicutter” are used interchangeably. The term “flight” indicates a portion of a segmented bit shaft, which comprises cutting arms. The term “cutting arm” is interchangeable with “cutter.” The terms “resin” and “grout” are also used interchangeably.

[0046] The helical drag bits of the invention provide an advancement mechanism that move cutters along the circumference of a pilot hole, such as a pilot rock bolt hole. Simultaneously, the bit advances the cutter along the length of the pilot hole, thereby introducing machined grooves into the walls of the pilot hole. The rates of cutter movement along the circumference and length of the pilot hole may be varied independently to produce a variety of geometries, including evenly and unevenly spaced grooves.

[0047] Two exemplary embodiments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com