Co-Ni-base alloy

a technology of ni-base alloy and co-ni-base, which is applied in the direction of spring/damper, mechanical apparatus, and wound springs, etc., can solve the problems of insufficient conventional mainsprings, limited space within mechanical wrist watches, and inability to increase etc., to achieve high output torque without increasing the thickness or width of springs, and favorable plastic workability properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

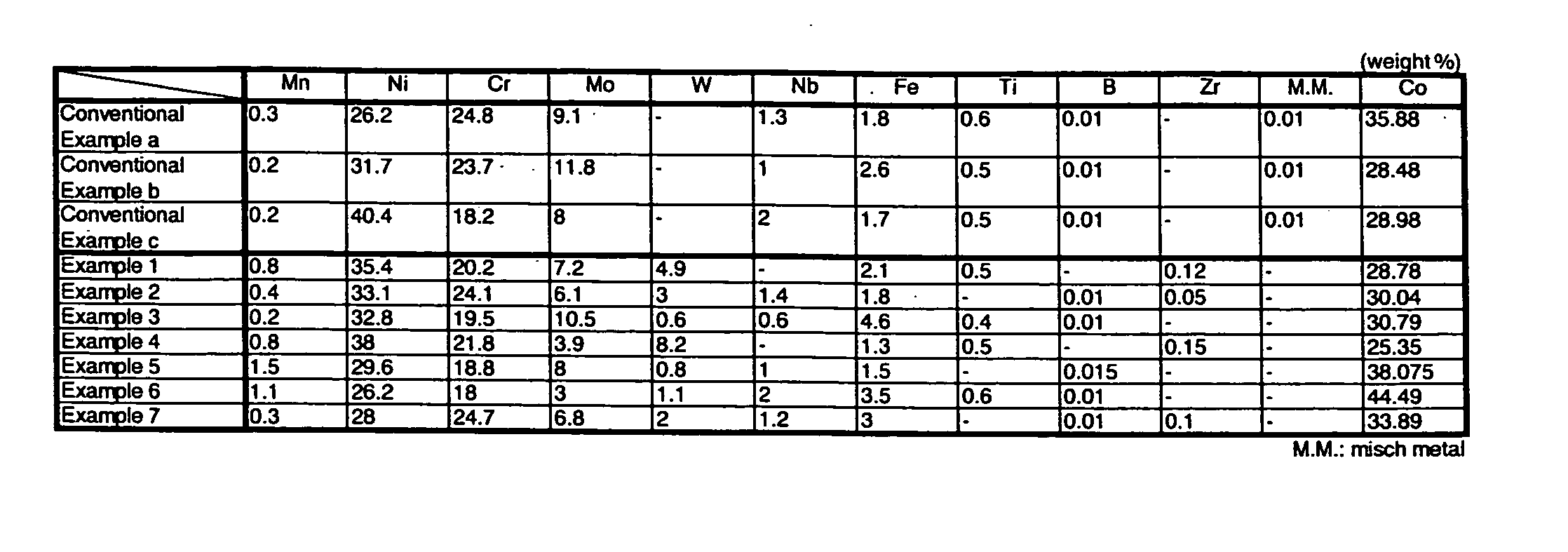

A composition of the Co—Ni-base alloy according to the present invention comprises at least Co, Ni, Cr, Mo, W and Fe, and, in terms of percentages by weight, from 25% to 45% of Co, from 25% to 40% of Ni, from 18% to 26% of Cr, from 3% to 11% of Mo, from 0.5% to 9% of W, wherein a sum of Mo and W is from 4% to 13% by weight, and from 1.1% to 5% of Fe, and, further, has fine deformation twins in a parent phase. Preferably, the composition of the alloy comprises on type or more of elements among Nb, Mn, B, Zr and Ti, and percentages by weight of the elements contained in the alloy are as follows: 0≦Nb≦2; 0≦Mn≦2%; 0≦B≦0.02%; 0≦Zr≦0.2%; and 0≦Ti≦1%.

A mainspring is produced from the Co—Ni-base alloy having the aforementioned composition.

Since the alloy which is a material of the mainspring according to the invention has a favorable plastic workability and has a low stacking fault energy, it has a high work-hardening ability. When it is subjected to cold-plastic working, fine deformatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com