Refrigerant compressor

a compressor and refrigerant technology, applied in the direction of pump components, positive displacement liquid engines, liquid fuel engine components, etc., can solve the problems of increasing the manufacturing cost of the muffler insignificantly or not at all, achieving partly substantial noise muffling, and improving thermal isolation. , the effect of excellent isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

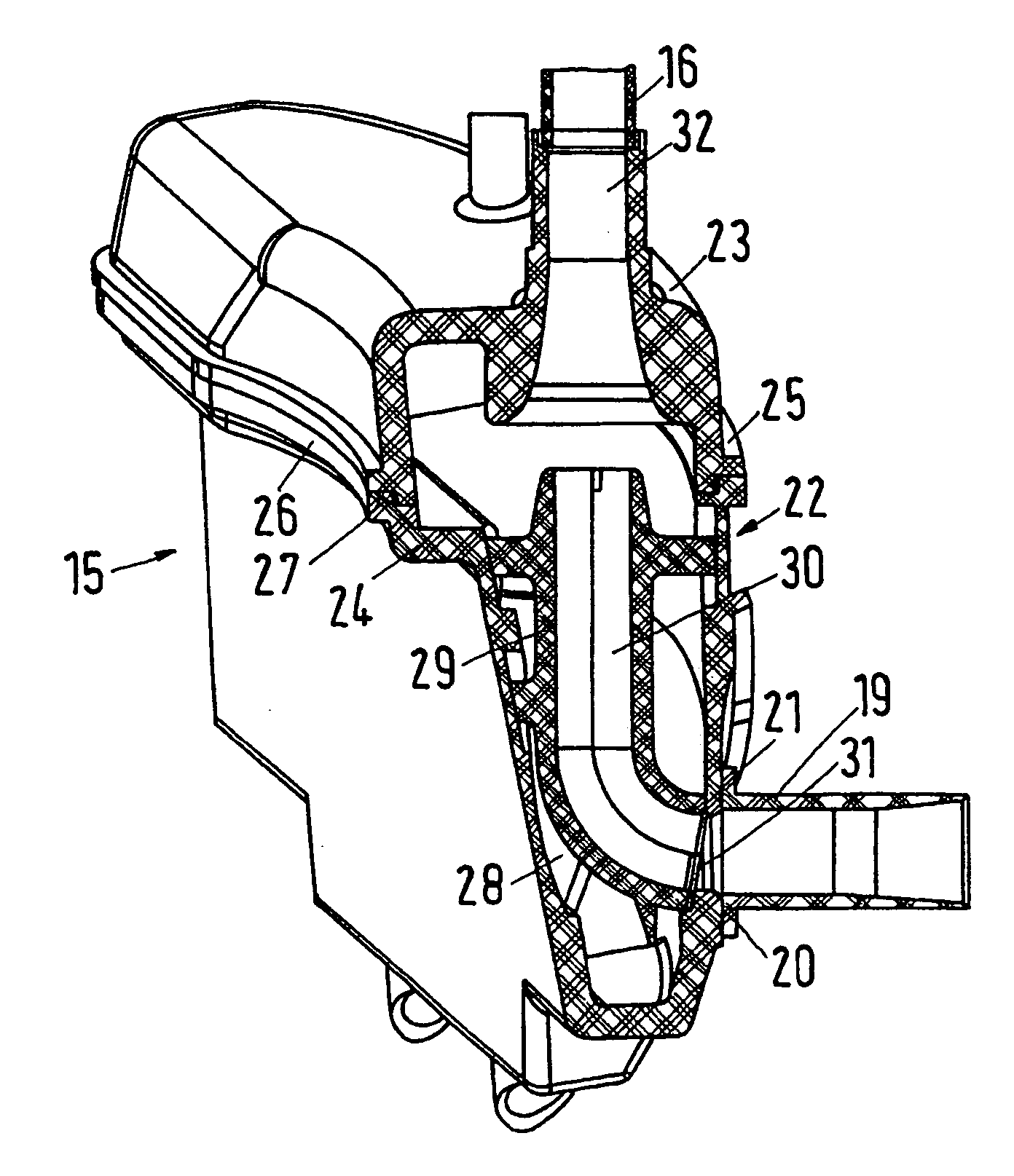

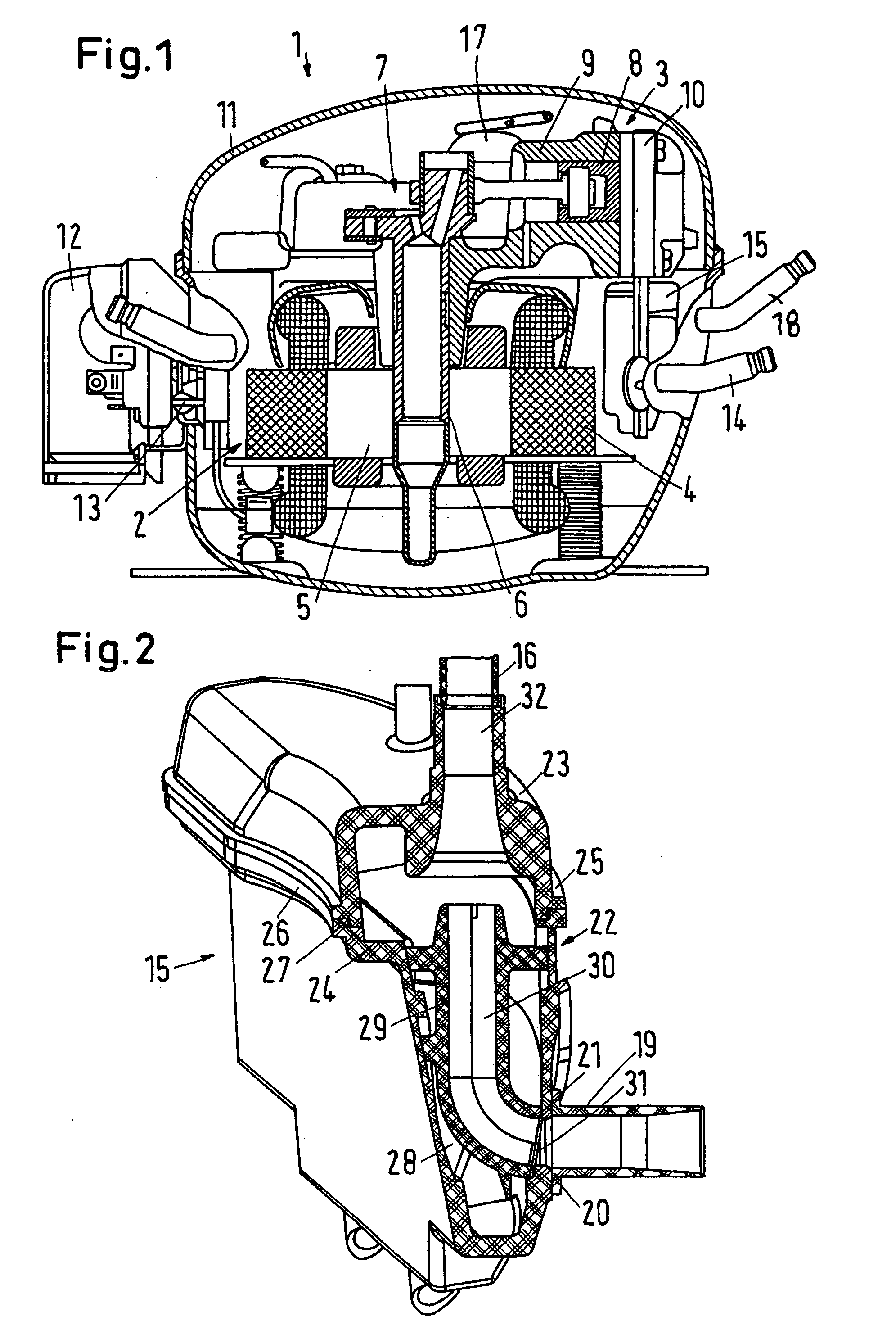

[0019]FIG. 1 shows a refrigerant compressor 1 with a motor 2, which drives a compressor 3. The motor 2 has a stator 4 and a rotor 5. The rotor 5 is connected with a shaft 6, which drives a piston 8 in a cylinder 9 via a crankshaft drive 7. The cylinder 9 is closed by a cylinder head 10, in which, in a manner known per se, valves are located, which control the filling of a compression chamber in the cylinder 9 with refrigerant gas, or the discharge of the refrigerant gas from the compression chamber, respectively.

[0020] The parts mentioned are enclosed in a case 11, which encloses the motor 2 and the compressor 3 hermetically. The outside of the case is provided with an electronic connection device 12, if required with a control, which controls the operation of the motor 2 in dependence of predetermined values, for example the refrigeration requirement of a refrigerator, not shown in detail. The device 12 is connected with the motor 2 via lines 13 guided through the case.

[0021] Ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com