Lubricating oil compositions for automatic transmissions

a technology of automatic transmission and lubricating oil, which is applied in the direction of lubricant composition, fuel, organic chemistry, etc., can solve the problems of poor fuel efficiency, driver discomfort, failure to prevent the occurrence of scratch noise and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

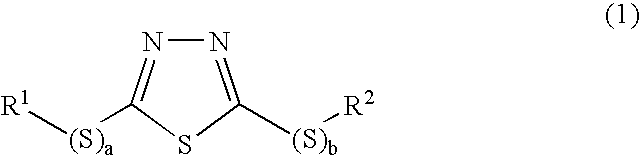

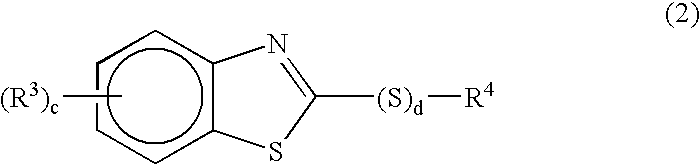

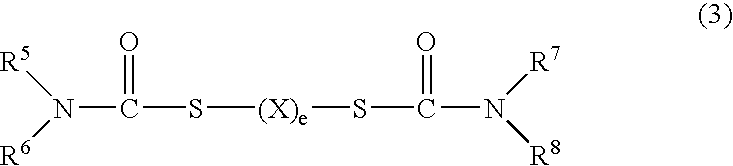

Method used

Image

Examples

example 2 example 3 example 4

Base Oil Hydrocracking mass % Mineral Oil A.sup.1) Hydrocracking mass % 100 100 100 100 Mineral Oil B.sup.2) Solvent Refining mass % Mineral Oil A.sup.3) Base Oil Viscosity (100.degree. C.) mm.sup.2 / s 4.1 4.1 4.1 4.1 Concentration of Sulfur mass % 0.000 0.000 0.000 0.000 derived from Base Oil Polyalkylmethacrylate A.sup.4) mass % 6 6 6 6 Polyalkylmethacrylate B.sup.5) mass % ATF Additive Package.sup.6) 8 8 8 8 Ashless Dispersant A.sup.7) 1.5 1.5 1.5 1.5 Calcium Sulfonate.sup.8) mass % 0.09 0.09 0.09 0.09 Sulfur-based Thiadiazole.sup.9) mass % 0.05 0.2 Additives Dithiocarbamate.sup.10) mass % 0.2 Dithiophosphate.sup.11) mass %0.2 Trithiophosphite.sup.12) mass % Polysulfide A.sup.13) mass % Polysulfide B.sup.14) mass % Element Phosphorus mass % 0.030 0.030 0.030 0.048 Concentration Calcium mass % 0.011 0.011 0.011 0.011 Boron mass % 0.007 0.007 0.007 0.007 Sulfur mass % 0.019 0.073 0.061 0.036 Element Phosphorus 1.00 1.00 1.00 1.00 Ratio Calcium 0.36 0.36 0.36 0.23 Boron 0.23 0.23 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| carbon number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com