Production apparatus and method of fluoride crystal, and crucible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0101] In this example, a calcium fluoride crystal was produced according to a procedure shown in FIG. 6. Hereinafter each process will be explained.

[0102] (Prescription, Mixing Process)

[0103] A powdery calcium fluoride material was placed in a container. 0.08 mol % of a scavenger (ZnF.sub.2) was measured based on the material, and added to the container with the material. The container used has a capacity about double as much as the volume of the material. The material and the scavenger were mixed by rotating the container for about 1 hour.

[0104] (Refining Process)

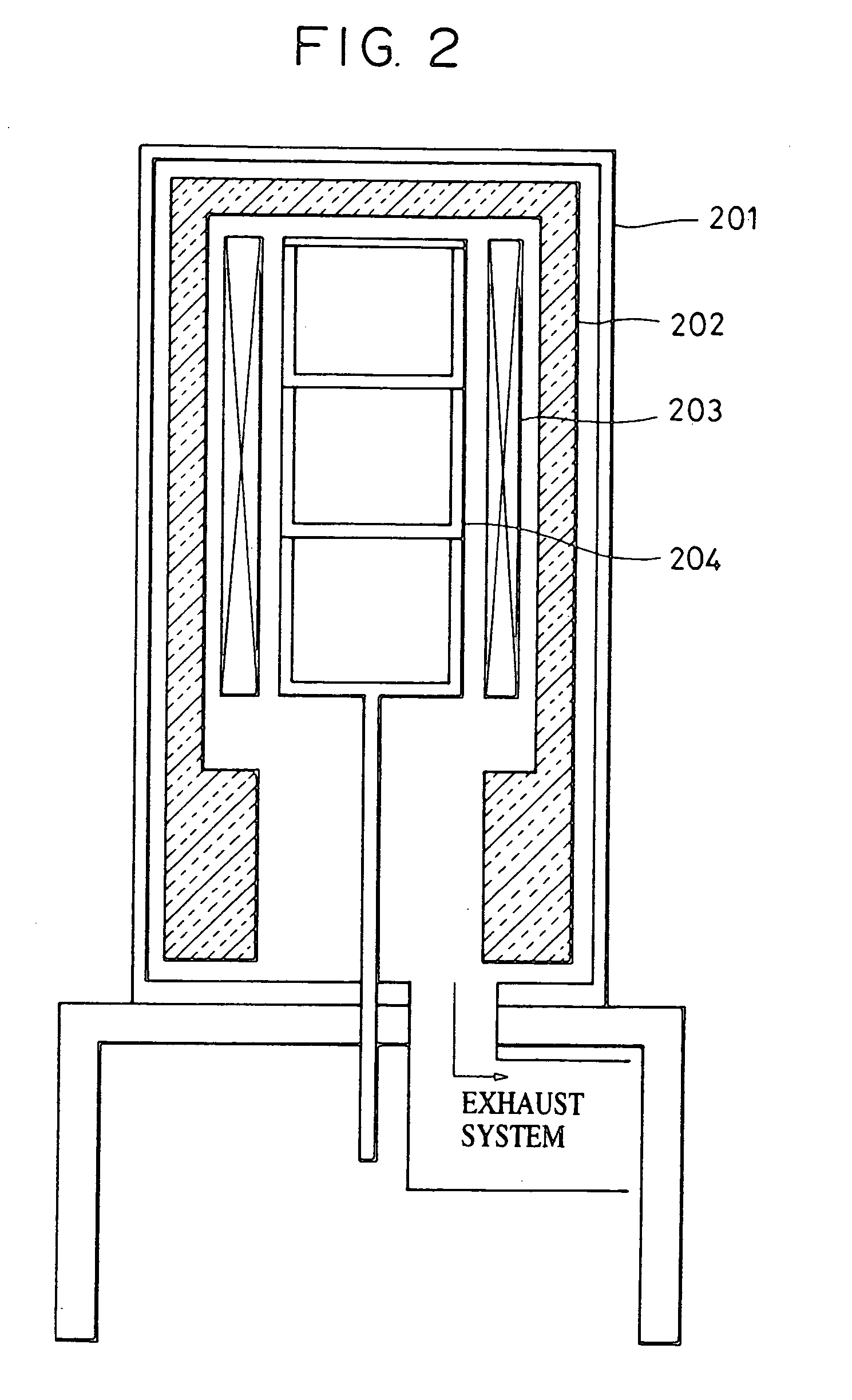

[0105] The material was refined with a refining furnace shown in FIG. 2.

[0106] A multi-stage crucible shown in FIG. 1A with three stages was used.

[0107] After filling the prepared material in each stage of the crucible, the crucible was set in the refining furnace. By vacuum-exhausting the inside of the chamber 201, the moisture in the material 205 was eliminated.

[0108] While maintaining the vacuum degree at 5.times.10.su...

example 2

[0123] In this embodiment, a fluoride crystal was produced in the process the same as Example 1 except that the crucible shown in FIG. 1B was used instead of the crucible of the refining furnace of Example 1. The degassing holes with a 3 mm diameter were provided at 8 positions symmetrically.

example 3

[0124] In this embodiment, a fluoride crystal was produced in the process the same as Example 1 except that the multi-stage crucible with the configuration of FIG. 4B was used as the growth furnace crucible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com