Safety component moulded in a1-si alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] The three alloys A, B and C with the composition (by weight %) shown in Table 1 below, which differ essentially in their copper content, were cast in the form of 18 mm diameter test shell pieces according to standard NF A 57-702.

1 TABLE 1 Alloy Si Fe Cu Mg Ti A 6.95 0.12 0.01 0.60 0.12 B 6.85 0.13 0.47 0.58 0.13 C 6.87 0.13 0.94 0.59 0.13

[0043] After casting, the test pieces are hot isostatically compacted in order to eliminate all microporosity, this compaction being representative of the different moulding processes including a high pressure compaction phase during solidification such as die casting, squeeze casting, thixocasting, rheocasting or casting with lost foam models under isostatic pressure, or after solidification, such as casting--die stamping.

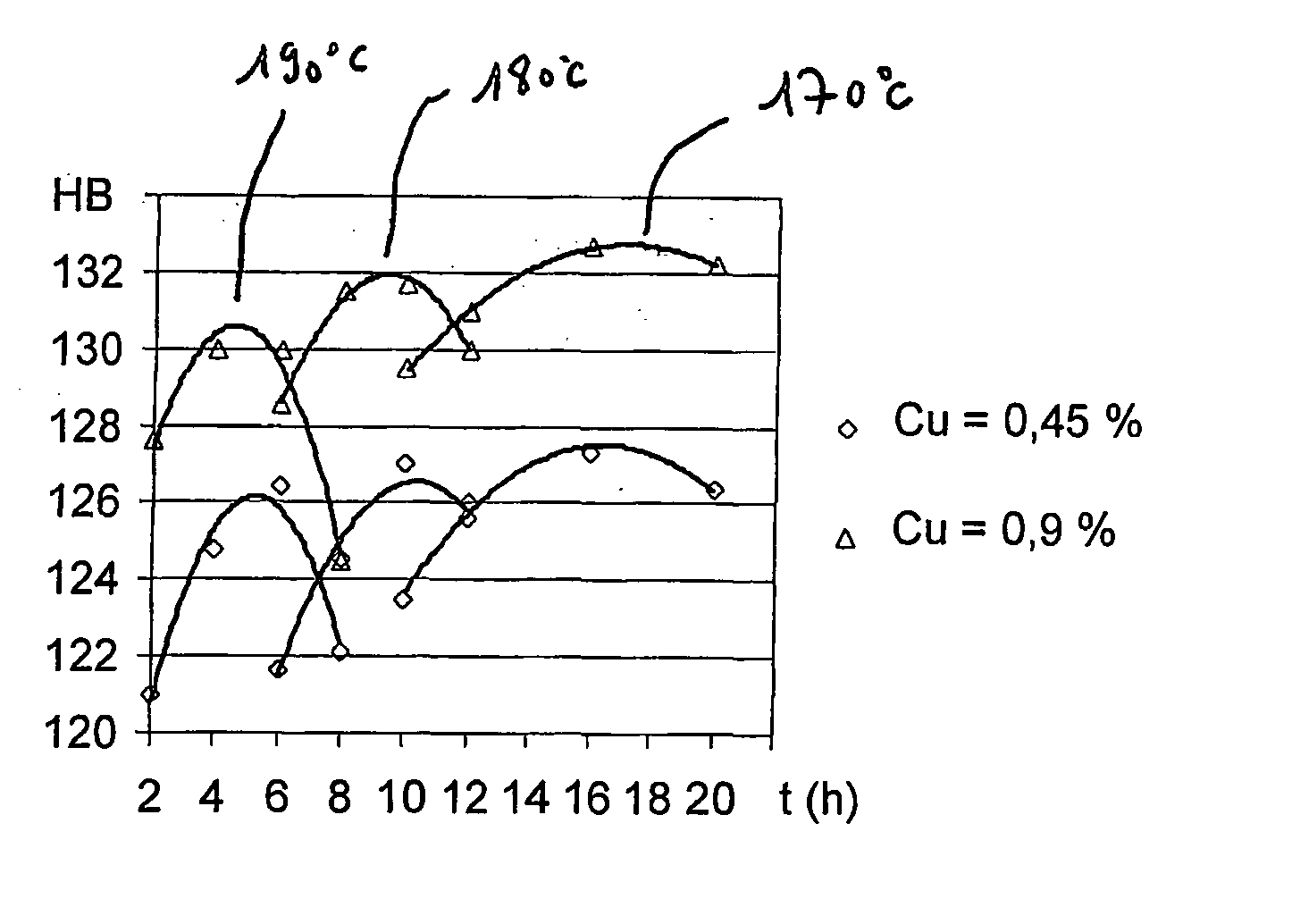

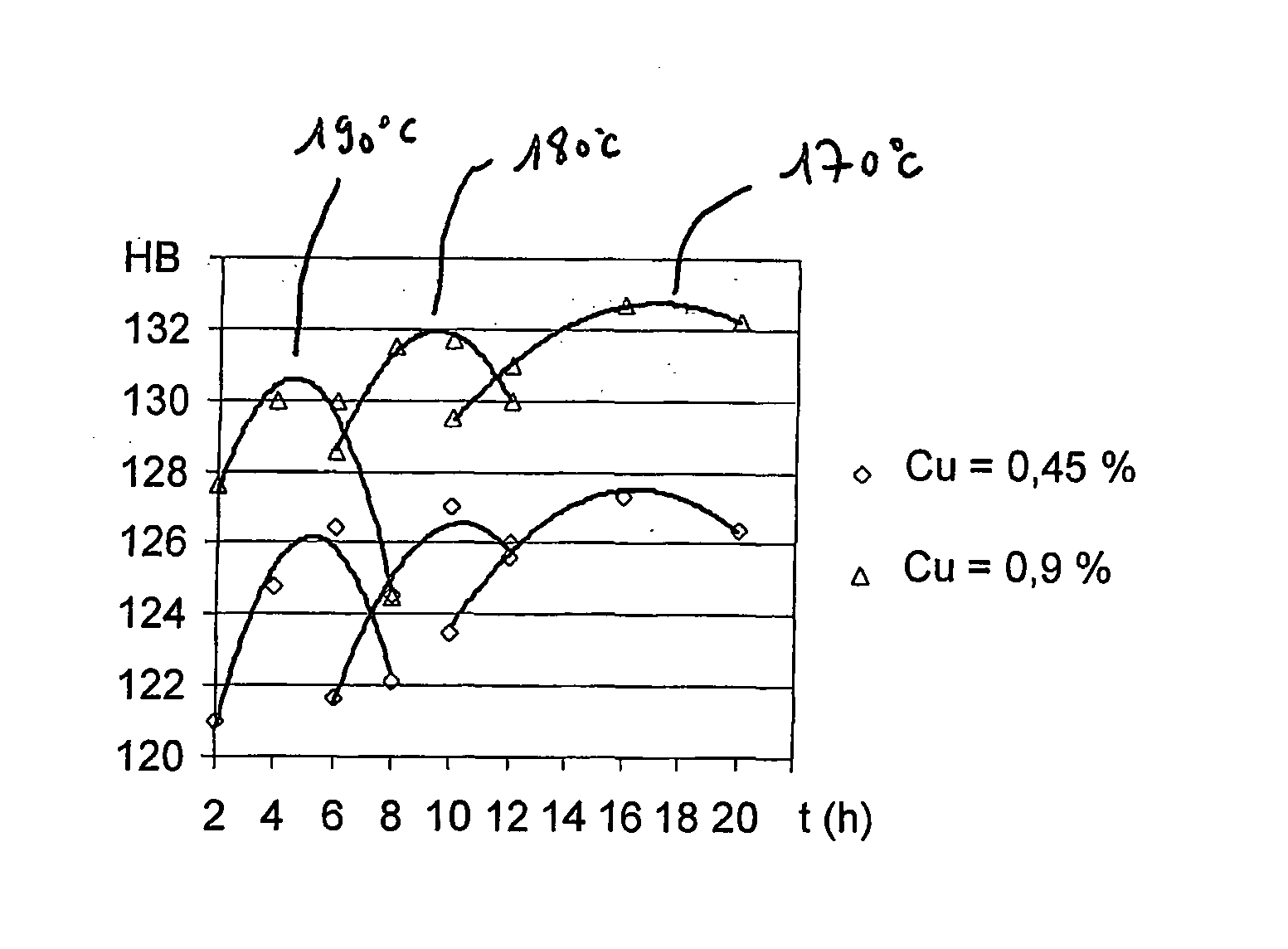

[0044] The test pieces are then solution heat treted with preliminary levels in order to redissolve eutectics containing copper, and a main level for homogenisation and globulisation of eutectic silicon lasting for 16 h at ...

example 2

[0054] Test pieces with three alloys D, E and F at 4% silicon were prepared under the same conditions as in example 1. The composition of each test piece (% by weight) is given in Table 4:

4 TABLE 4 Alloy Si Fe Cu Mg Ti D 4.0 0.11 0.03 0.63 0.13 E 3.9 0.08 0.44 0.63 0.13 F 4.1 0.09 0.85 0.64 0.13

[0055] After the different ageings, the same parameters were measured as for example 1, and the values are given in Table 5:

5TABLE 5 Alloy Ageing R.sub.m R.sub.p0.2 A HB Q D 6 h / 160.degree. C. 342 266 15.0 119 518 D 10 h / 170.degree. C. 358 309 11.2 124 515 E 16 h / 170.degree. C. 378 322 11.6 132 538 F 16 h / 170.degree. C. 388 319 9.3 132 533

[0056] Firstly, it was observed that the alloy D without any copper and with 4% silicon has better ultimate tensile strength and better elongation, and therefore a substantially improved quality index, than alloy A in example 1 with 7% of silicon.

[0057] It is also observed that with copper alloys and ageing according to the invention, the ultimate tensile st...

example 3

[0058] Alloys E and F in example 2 were replaced by alloys E' and F' with the same composition except for iron, and the iron content of these two alloys was modified to 0.18 and 0.16% respectively. With the same heat treatment comprising 16 h ageing at 170.degree. C., the elongations A obtained were equal to 7.5% and 6.8% respectively, representing reductions of 35% and 27% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com