Vacuum fresh-maintaining plastic bag

a plastic bag and vacuum technology, applied in the field of vacuum fresh-maintaining plastic bags, can solve the problem of not being able to put the whole plastic bag into the vacuum chamber for vacuum-pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

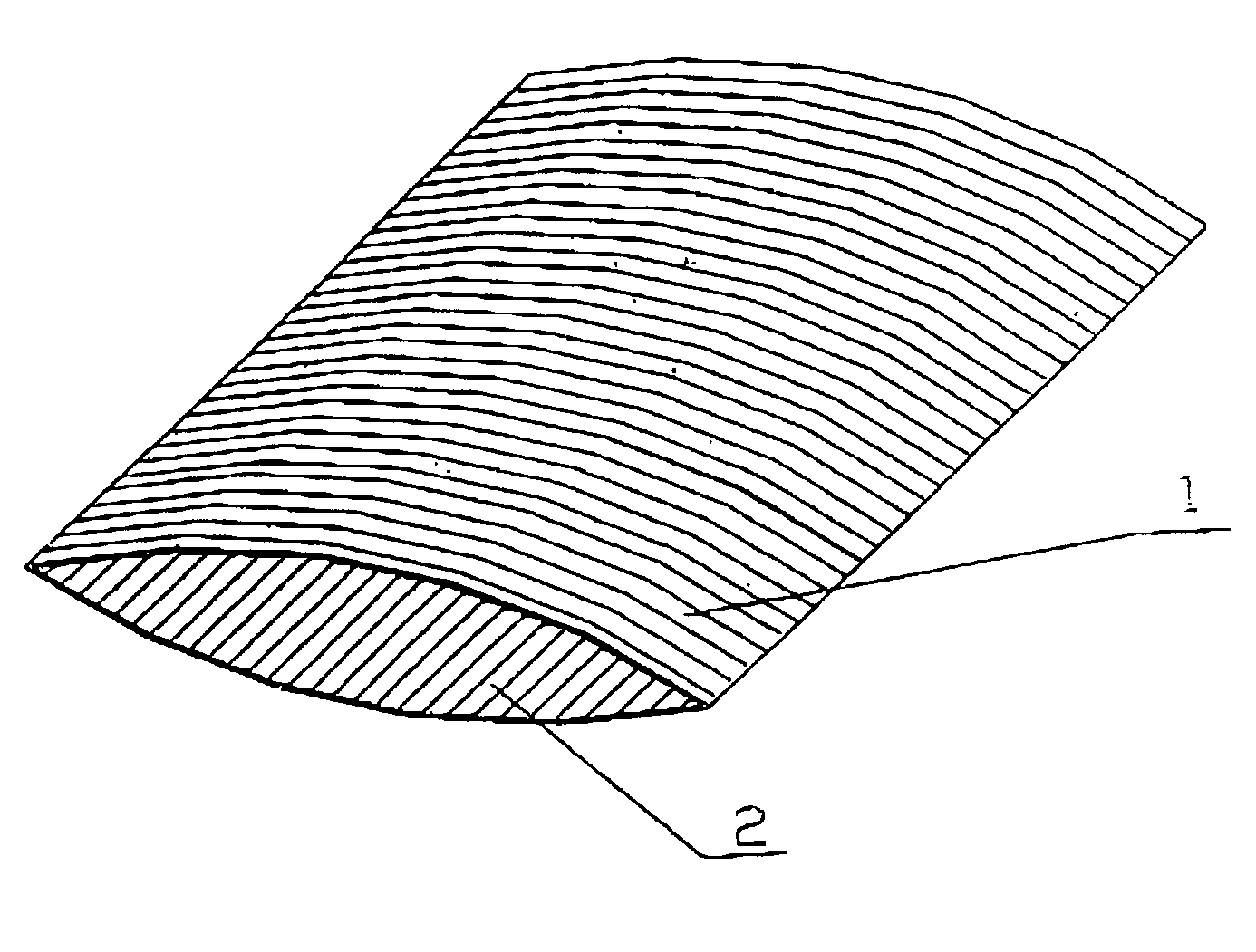

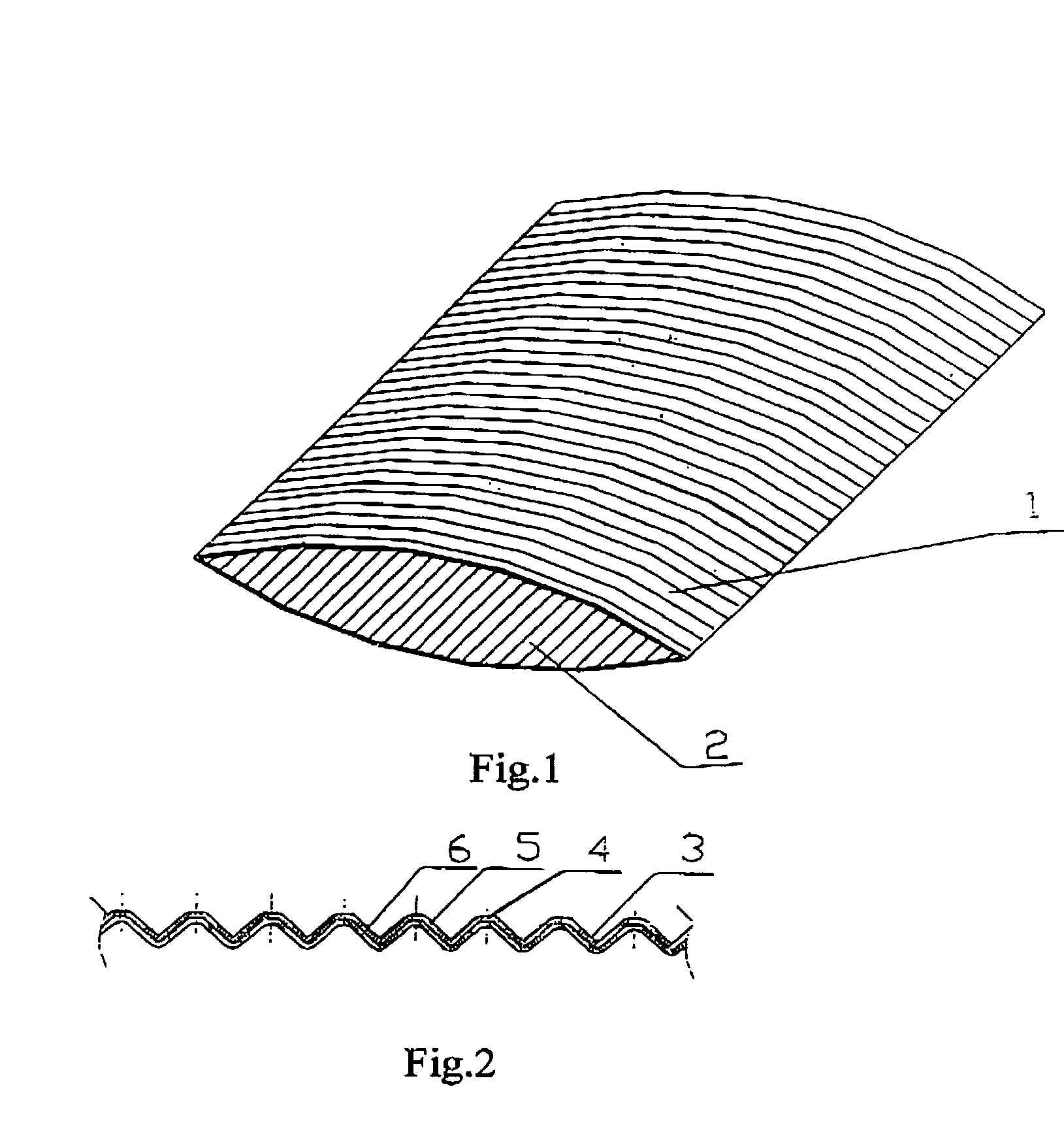

[0017] As shown in the FIG. 1 and FIG. 2, the vacuum fresh-maintaining plastic bag includes two layer thin film, and the opposite inner surface of each of the thin film is in the shape of the parallel concave-convex channel, and the channels of the two opposite inner surfaces are intersected with each other by the angle of 0.degree.<.alpha..ltoreq.9-0.degree. therebetween.

[0018] The film (1, 2) includes two layers (5, 6), the inner layer 5 is made of the PE plastic material, while the outer layer 6 is made of the PA plastic material, the inner layer 5 and the outer layer 6 are recombined into the concave-convex channel shape, the channels 3 are arranged in line, and the films (5, 6) are in a wavy shape, the channels 3 of the film 5 and film 6 are intersected to each other by the angle of 0.degree.<.alpha..ltoreq.90.degree. therebetween after the films (5, 6) being packaged into the bag. The section of the above channels is in the triangle shape, and the distance ...

second embodiment

The Second Embodiment

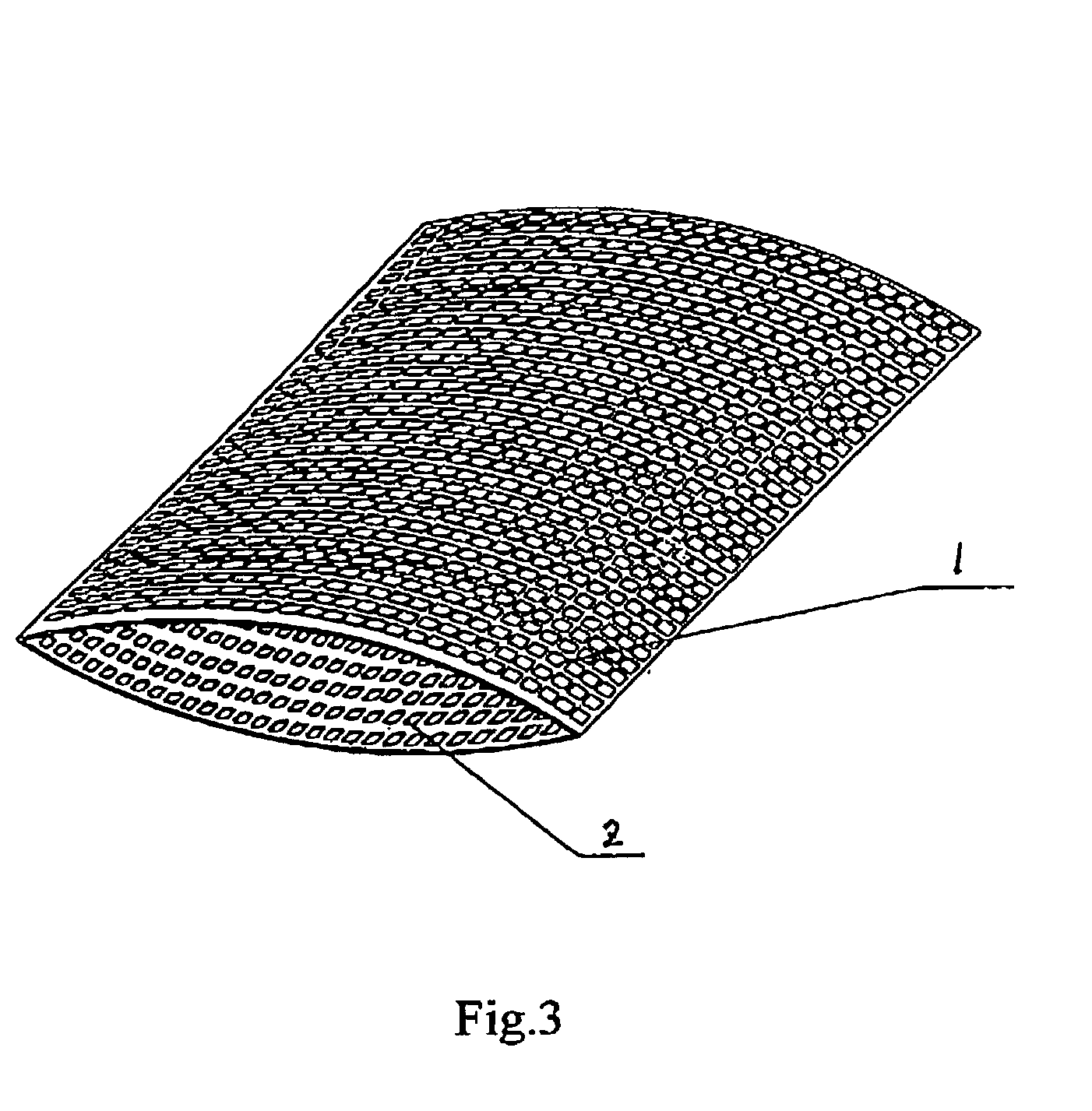

[0019] As shown in the FIGS. (3), (4), and (5), the vacuum fresh-maintaining plastic bag includes a two layer thin film, and the two opposite inner surfaces both have the concave pits. The recess direction of the said concave pits along the opposite inner surface is directed to the outside, and the pits of the two opposite inner surfaces are intersected or being faced each other. The said films (1, 2) are in two layers (5, 6), the inner layer 5 thereof is made of the PE plastic while the outer layer 6 is made of the PA plastic. The inner layer 5 and the outer layer 6 are pressed into the regularly arranged pits after they are recombined together. The pits on each of the two opposite surfaces are regularly arranged without communication to each other, the width of the pits are disposed in proportion with the distance between the pits in order to keep better air flowing, the route of the air flowing is shown in the FIG. (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com