Electrode metal material, capacitor and battery formed of the material and method of producing the material and the capacitor and battery

a technology of electrolytic capacitors and metal materials, which is applied in the direction of electrolytic capacitors, capacitor electrodes, cell components, etc., can solve the problems of low discharge rate, difficult to sufficiently reduce contact resistance at the surface, and increase internal resistance of capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[Example 1]

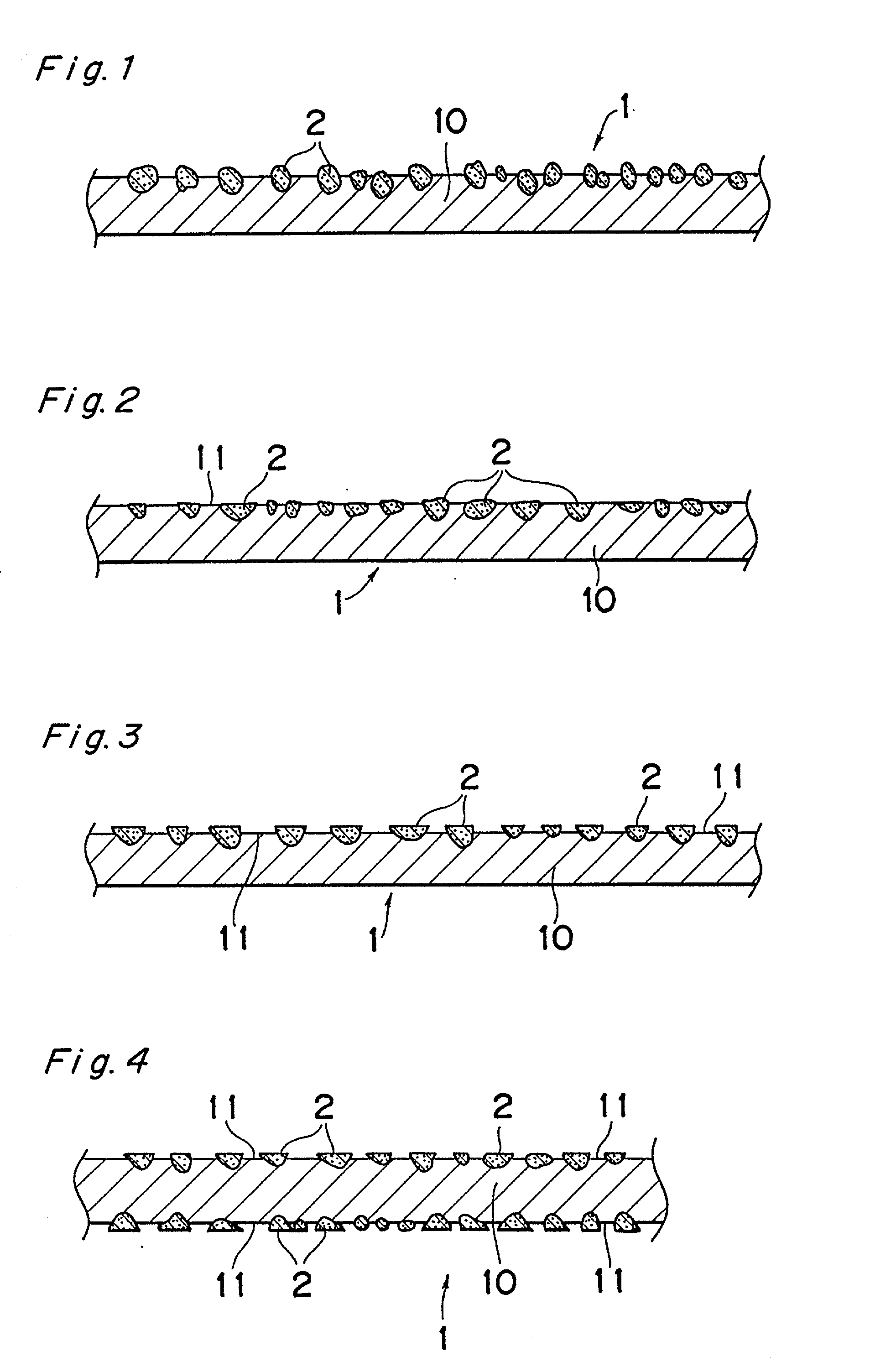

[0105] A valve metal was formed of high-purity aluminum foil of four-nine grades, having a thickness of 20 .mu.m. An electrode metal material was produced as described below. Acetylene black particles having an average particle diameter of 2 .mu.m were dispersed uniformly on the surface of the metal foil in an amount of 50% by weight with respect to the metal foil per unit area of the foil, and subjected to a line pressure of 100 kg / cm in a direction perpendicular to the surface of the foil by using reduction rollers. As a result, carbon-embedded metal foil, wherein numerous carbon particles were driven in the surface of the aluminum foil, was obtained.

example 2

[Example 2]

[0106] In the same way, an electrode metal material was produced as described below. Acetylene black particles having an average particle diameter of 2 .mu.m were dispersed uniformly on the surface of high-purity aluminum foil of four-9 grade, having a thickness of 20 .mu.m, at 50% by weight in the same way as described above, and subjected to a line pressure of 100 kg / cm.sup.2 in a direction perpendicular to the surface of the foil by using rollers. Numerous carbon particles were thus driven in the surface of the aluminum foil. After this, the carbon-embedded metal foil was subjected to electrolytic etching in a nitric acid-based etching solution to expose the carbon particles to the surface.

example 3

[Example 3]

[0107] In the same way, phenol-resin-based activated carbon particles having a particle diameter of 10 .mu.m were dispersed uniformly on the surface of etched high-purity aluminum foil of four-9 grade, having a thickness of 20 .mu.m, which is used as a valve metal material, and then subjected to a pressure of 100 kg / cm.sup.2 in a direction perpendicular to the surface of the foil by using reduction rollers. As a result, numerous carbon particles were driven in the surface of the aluminum foil. After this, the carbon-embedded metal foil was subjected to blasting to expose the carbon particles to the surface.

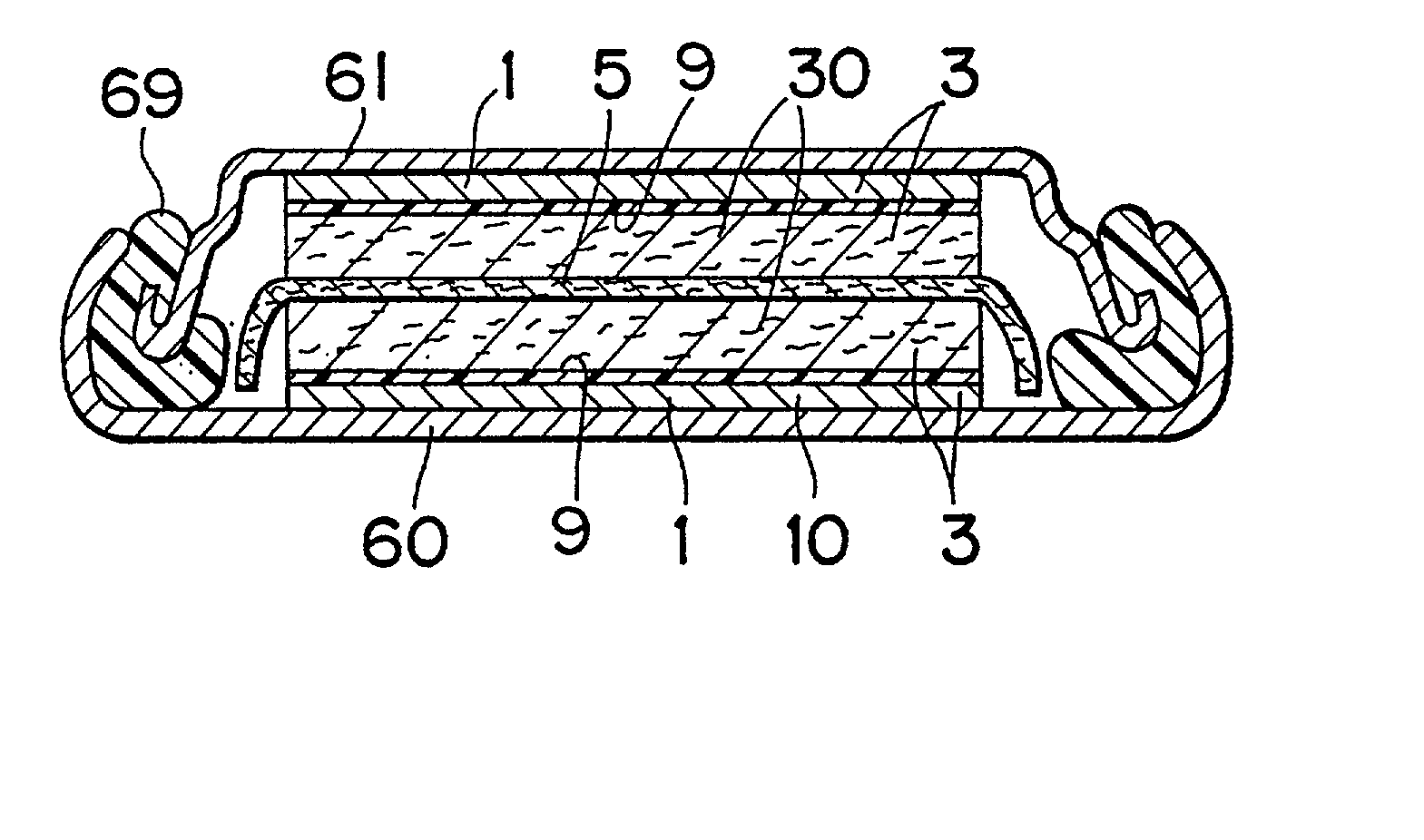

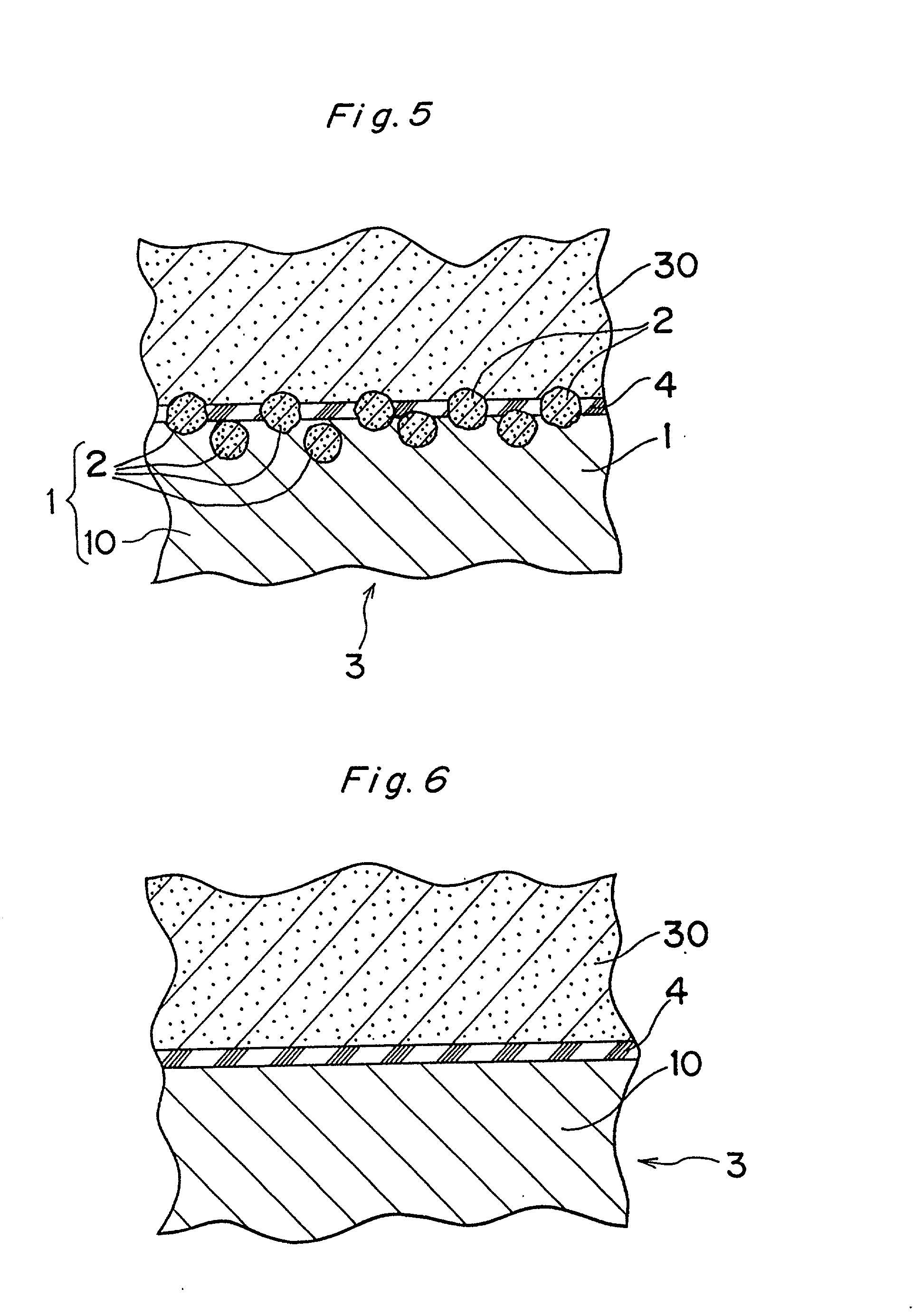

[0108] Electric double-layer capacitors were assembled by using these pieces of carbon-embedded metal foil for electrodes in accordance with Examples 1 to 3. To form a double-layer electrode, the carbon-embedded metal foil was coated with a paste including activated carbon particles. To prepare the, paste, after obtaining a powder mixture of phenol-resin-based activated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| withstand voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com