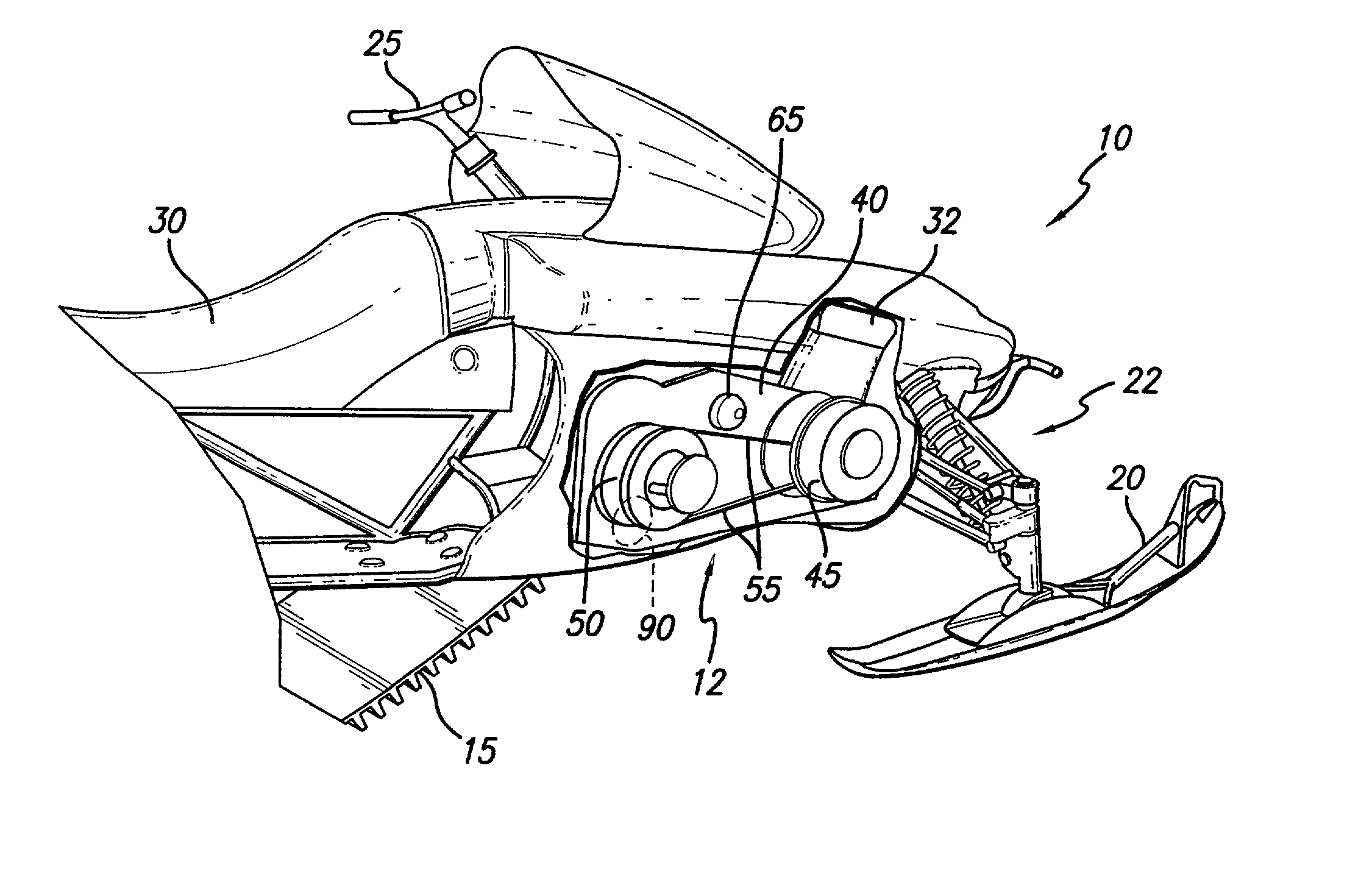

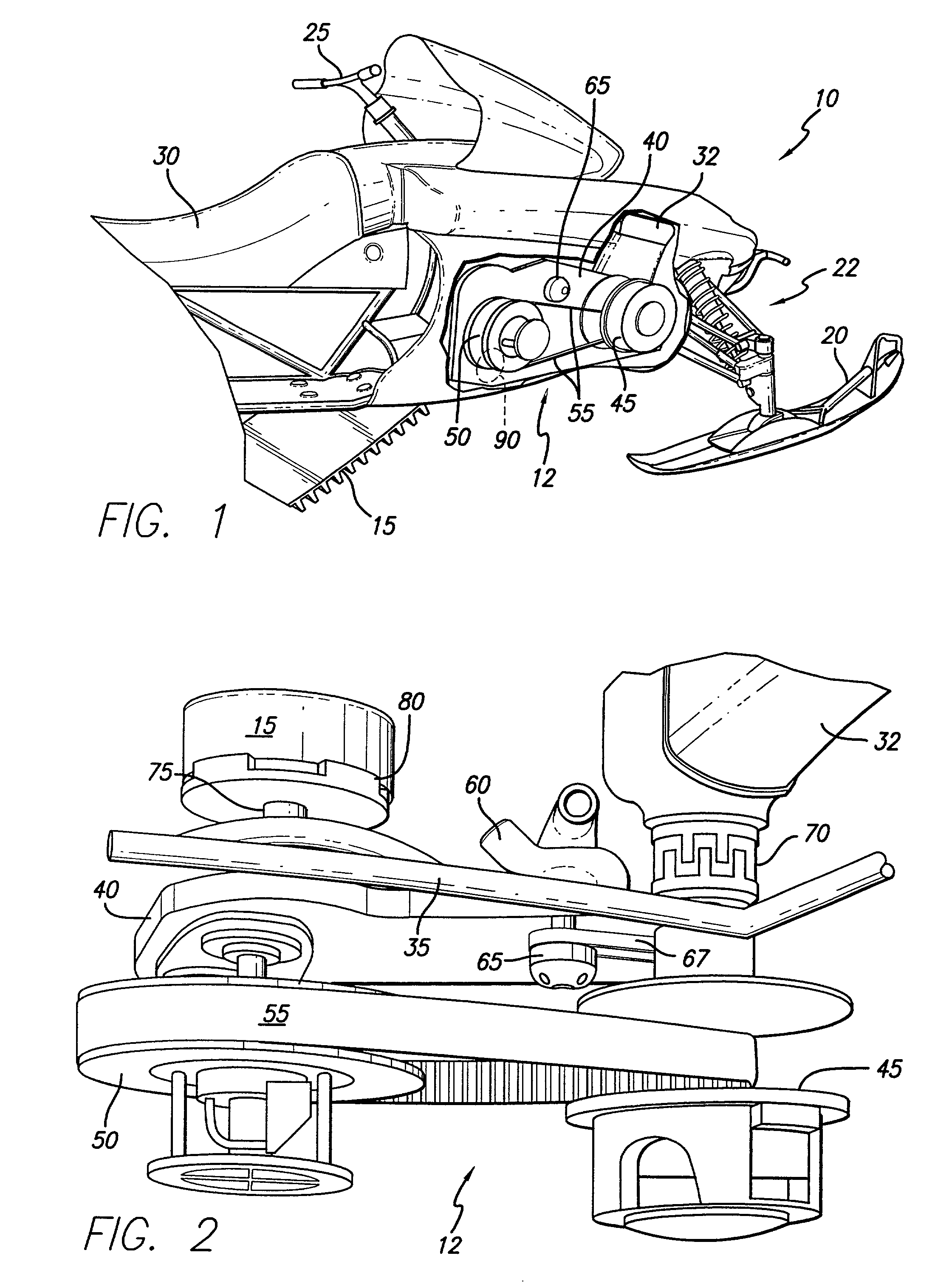

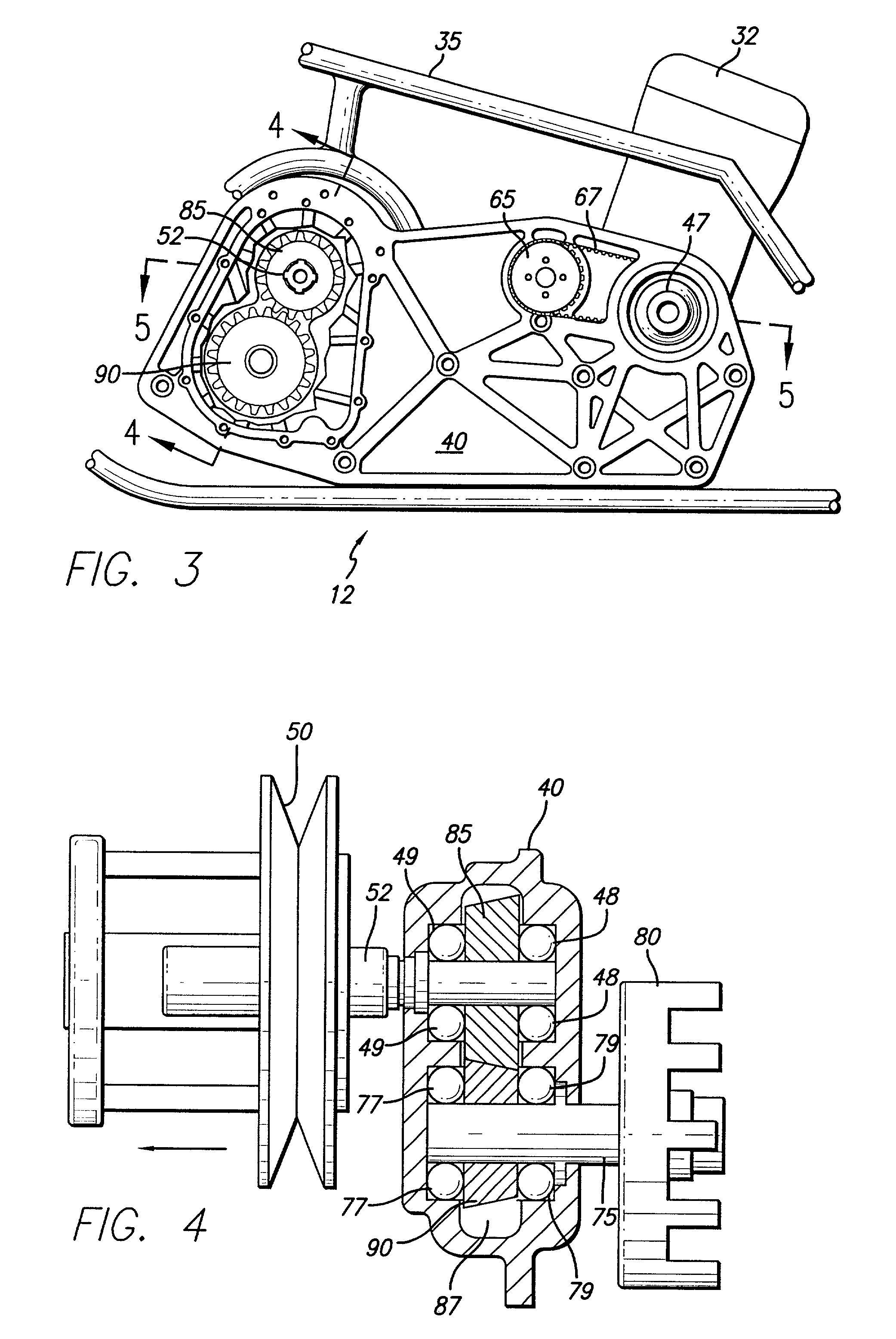

Snowmobile drive train

a drive train and snowmobile technology, applied in the field of snowmobiles, can solve the problems of reducing the efficiency of the drive belt, and increasing so as to prolong the operating life increase the efficiency of the drive belt, and maintain the operator's comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following paragraphs, the present invention will be described in detail by way of example with reference to the attached drawings. Throughout this description, the preferred embodiment and examples shown should be considered as exemplars, rather than as limitations on the present invention. As used herein, "the present invention" refers to any one of the embodiments of the invention described herein. Reference to various features of the "present invention" in this document does not mean that the claimed embodiments must include all the referenced features.

[0023] The present invention contemplates a snowmobile drive train that isolates the drive train pulleys from engine heat and vibration and mounts the pulleys rigidly, thereby maintaining precise pulley alignment. In addition, the present invention eliminates the jack shaft and chain drive found on conventional snowmobiles, and instead mounts two gears in a support member. This decreases drive train weight and allows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com