Cobalt recovery process

a recovery process and cobalt technology, applied in cobalt compounds, nickel compounds, inorganic chemistry, etc., can solve the problem that iron carbonyl cannot be completely separated from nickel carbonyl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

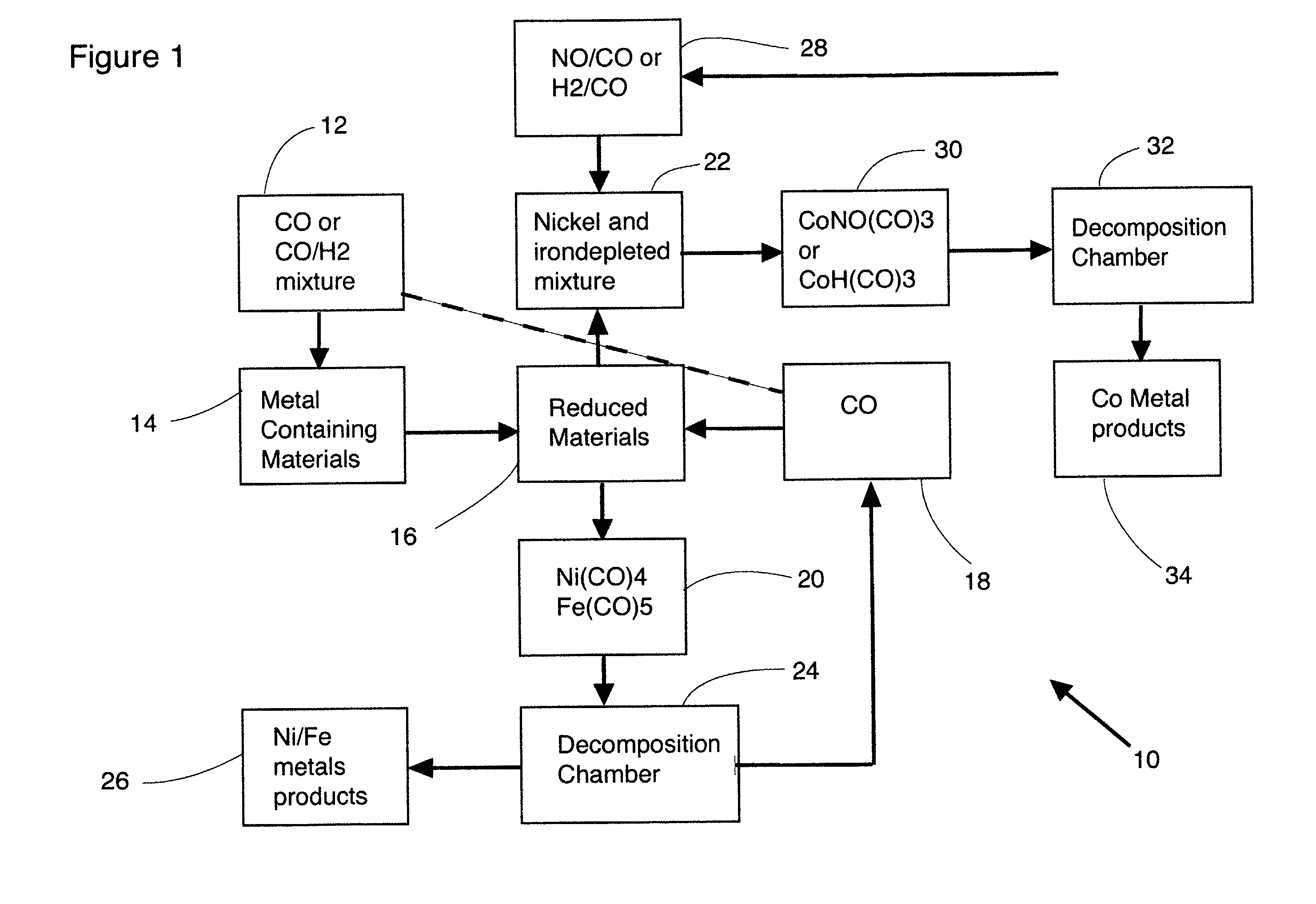

[0063] A mixture of Ni, Fe, Co oxides in amounts Ni (85 Kg), Fe (1 kg), Co (12 Kg) and a 3 Kg mixture of other metal oxides (Cr, Mn, Cu, Zn) (14) was reduced with CO / H.sub.2 mixture (12) as described in GB Patent Nos. 323,332 and 324,382. The chamber was then purged with either argon or nitrogen and the temperature of the reduced mixture of metals was lowered to 80-90.degree. C. Carbon monoxide gas was then passed through the mixture of reduced metals, under 10-20 bar pressure to produce metal carbonyls (16). Resultant nickel carbonyl, iron carbonyl and CO mixture was passed through the chemical vapour deposition (CVD) reclaim system (20) and metal carbonyl-depleted CO recycled into vessel (16). At temperatures of less than 100.degree. C., the cobalt carbonyl appears to remain as a coat on the surface of the cobalt metal to significantly reduce the cobalt carbonylation reaction rate. The concentration of Fe(CO).sub.5 and Ni(CO).sub.4 in the gas mixture was monitored to ensure essent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com