Process for producing semiconductor device

a technology of semiconductor devices and processing equipment, applied in the direction of chemistry apparatus and processes, plasma technique, cleaning using liquids, etc., can solve the problems of inefficient conversion of plasma formed in high density into negative ions, difficult to achieve high efficiency, and decrease in plasma density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

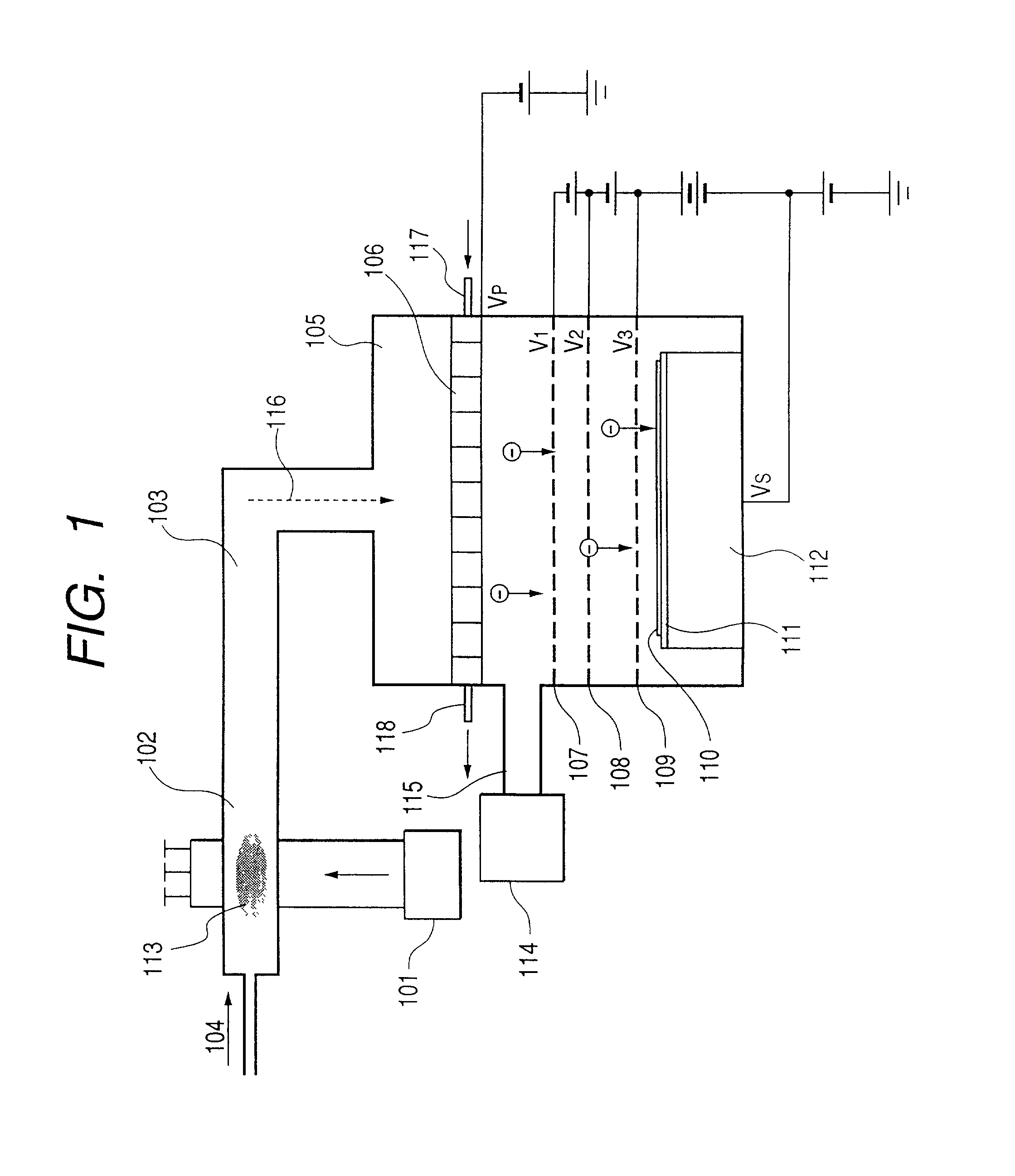

[0062] In the present Example, the apparatus shown in FIG. 1 was used in a cleaning process carried out before a film for upper-layer metal wiring is formed, in a via hole forming process for connecting different wiring layers of multi-layer wiring in semiconductor fabrication processes, and whether or not any charge-up damage occurred was examined.

[0063] Native oxide films or crystal defects brought in by ion bombardment at the time of etching remain at the bottoms of via holes formed above the silicon substrate surface. Hence, if second-layer metal wiring is formed in the state the via holes are left as they are, the native oxide films or crystal defects cause increase of the resistance of the via holes to bring about circuit retardation or wiring faulty conduction. Accordingly, these residual matter must be removed by cleaning or the like. At present, methods making use of plasma are widely and commonly used. The problem of these methods is the phenomenon of charge-up caused by p...

example 3

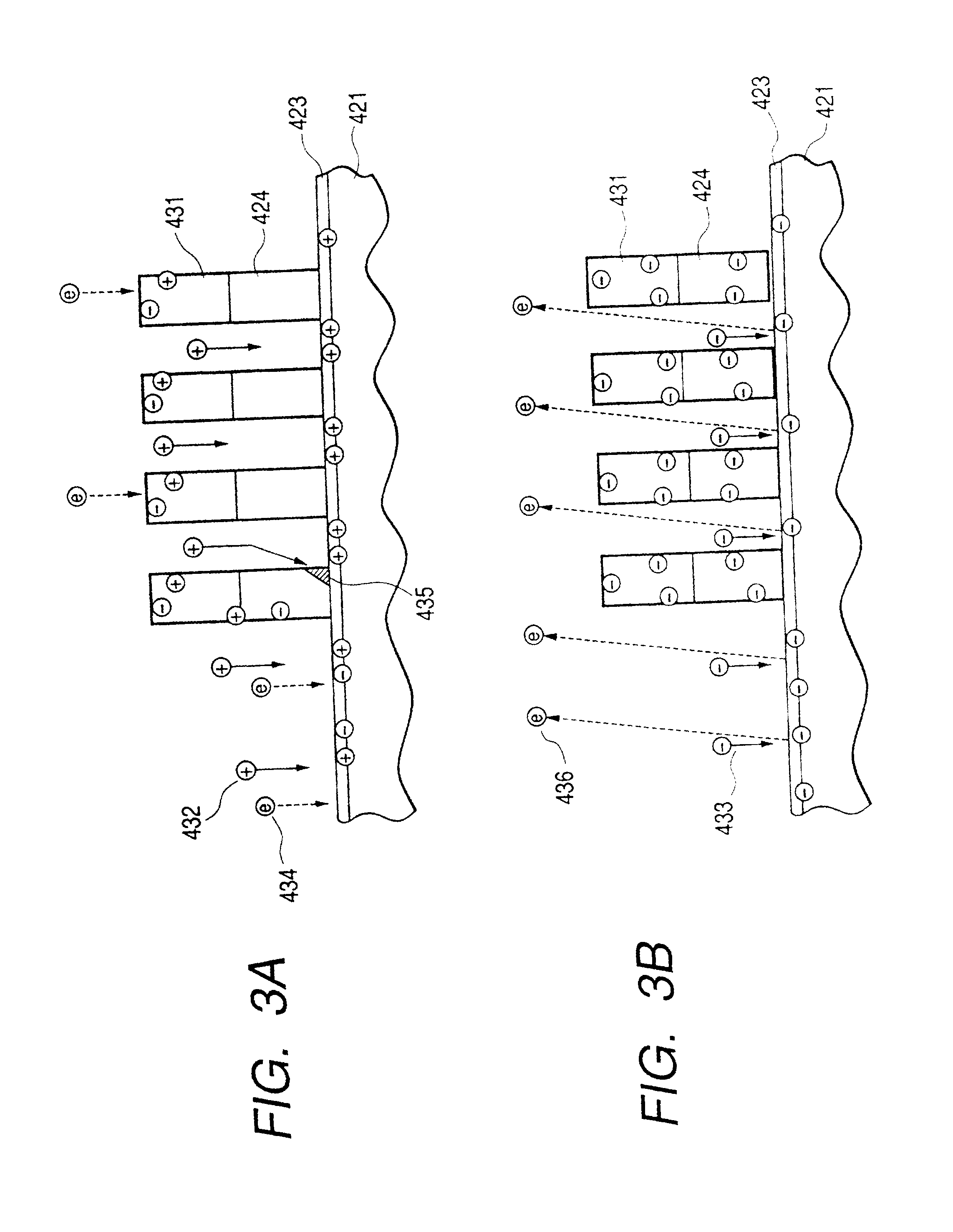

[0071] In the present Example, an instance is described where the apparatus shown in FIG. 3 was used and the second gas for cooling the plasma was fed in the form of neutral active particles.

[0072] By using the above apparatus, the etching rate of the polycrystalline silicon film was measured in the same manner as in Example 1. In this case, the wafer having a silicon oxide film on which a non-doped polycrystalline silicon film was deposited was used as the article 310 to be processed.

[0073] First, the article 310 to be processed was placed on the supporting stand 312 of the apparatus shown in FIG. 3. Thereafter, the plasma generating space 302 and the inside of the processing chamber 305 were evacuated via an exhaust means until they came to have a degree of vacuum of 5.times.10.sup.-6 Torr. Thereafter, 100 sccm of Cl.sub.2 gas was fed into the plasma generating space 302 through the first-gas inlet 304, and a throttle valve (not shown) installed to the exhaust means was adjusted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| incident energy | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com