Short pitch tooth chain

a technology of short-pitch tooth and chain, applied in the field of chain arts, can solve the problem of sound generation as the major source of noise, and achieve the effect of reducing noise levels and reducing noise levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

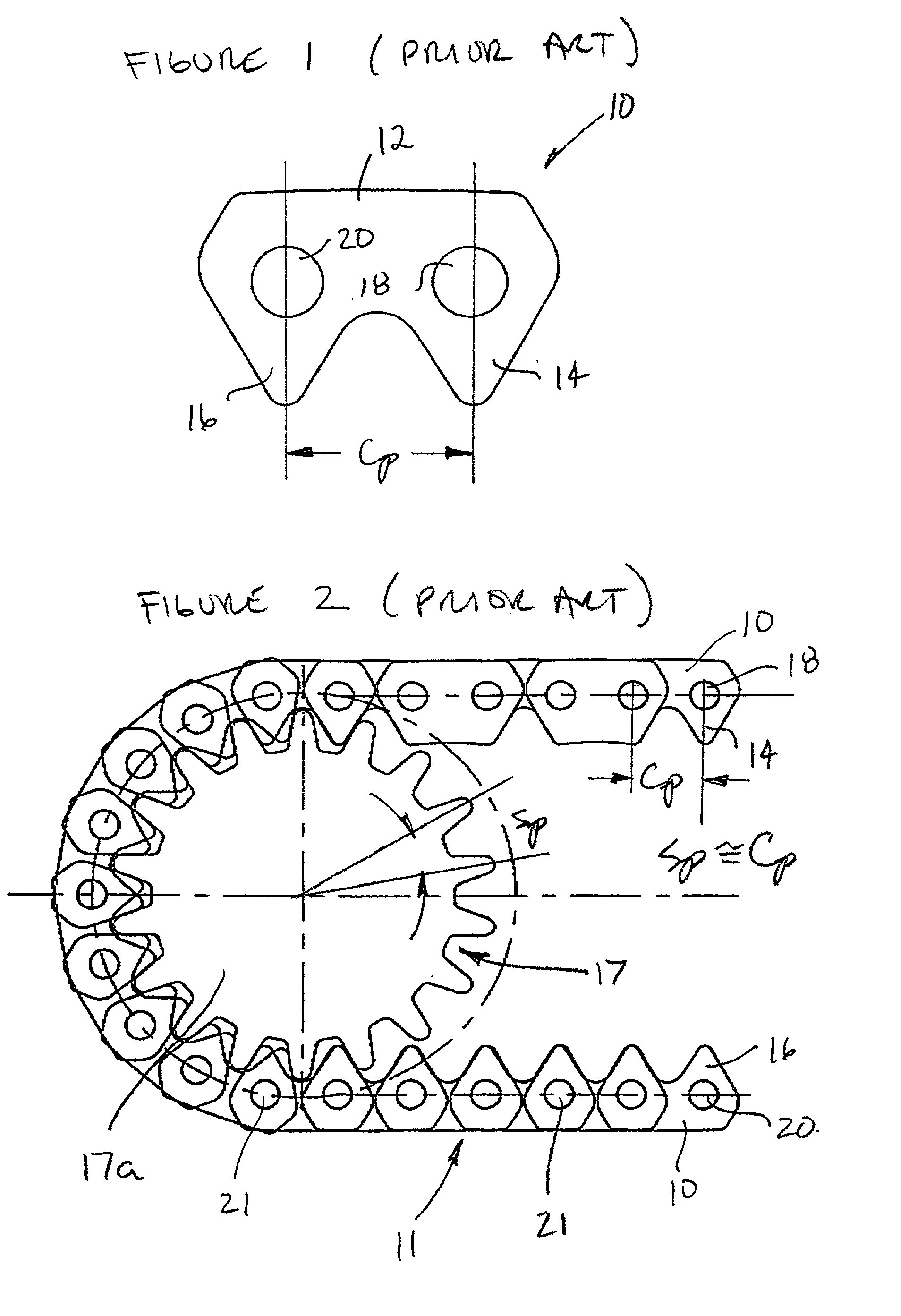

43. With reference to FIGS. 1 and 2, a conventional double-toed link 10 for a known inverted tooth chain 11 includes a body portion 12 having a first toe 14 spaced from a second toe 16. The toes 14, 16 consecutively engage adjacent and mutually conforming tooth spaces 17 associated with a sprocket 17a. The link 10 also includes a first aperture 18 and a second aperture 20 spaced apart from the first aperture. The apertures 18, 20 receive conventional pins 21 for joining together a number of different links, including links 10, to form the known inverted tooth chain 11.

44. The link 10 has a chain or link pitch C.sub.p conventionally defined as the distance between the centers of the first and second apertures 18, 20. It should be appreciated that a sprocket used in conjunction with the link 10 has a sprocket chordal pitch S.sub.p (conventionally defined as the distance separating adjacent teeth or tooth spaces) substantially equal to the chain pitch C.sub.p. Thus, for conventional c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com