Automatic charging device for an AGV on an automated container terminal and charging method therefor

a charging device and container terminal technology, applied in the direction of coupling device connection, transportation and packaging, instruments, etc., can solve the problems of agv power outage, agv simply stalling, agv battery failure, etc., and achieve the effect of fully charging within a short tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

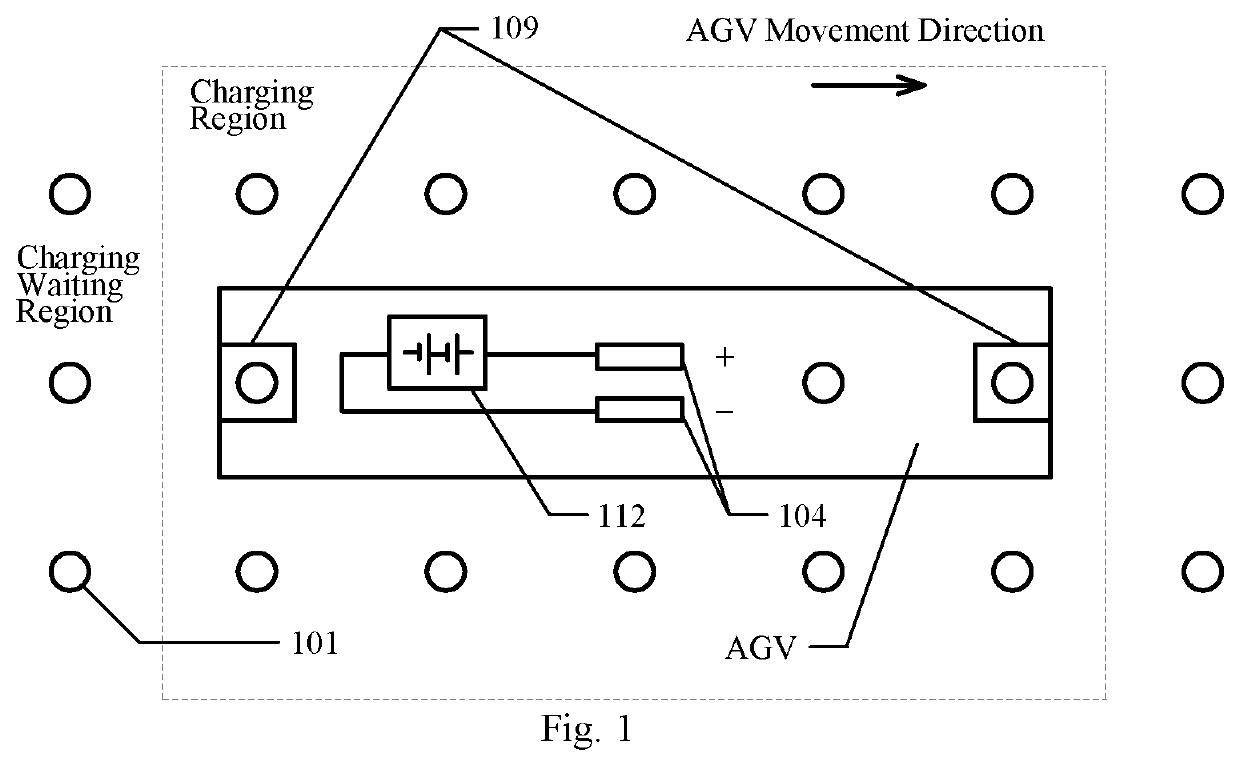

[0043]The entire AGV charging buffer region (place where AGV is charged or to be charged) is divided into a charging waiting region (place where AGV is waiting to be charged) and a charging region (place where AGV is charged). The division of the regions is mainly based on the RFID label array information. The RFID label array consists of several RFID labels with equal distances therebetween, as shown in FIG. 1. The array of circles inside the whole charging buffer region is referred to as RFID label 101 array. The region inside the dashed box is the AGV charging region, and the rectangle represents the AGV. The end of the vehicle which faces the direction of AGV′ movement is the front end of the vehicle, and the other end the rear end of the vehicle. The rectangles at the front and rear ends of the vehicle are two RFID read-write coils 109 arranged at front and rear ends of the AGV. The AGV mainly reads the information of RFID label in the charging region via the RFID read-write co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com