Microbial air sampler integrating media plate and sample collection device

a technology of air sampler and media plate, applied in the field of particle sampling, collection and analysis, can solve the problems of pharmaceutical products at risk of failing to meet the cleanliness level standards, real-time efficiency, and fabrication efficiency reduction, and achieve the effect of reducing or completely eliminating the risks associated with user handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Device For Microbial Air Sampling

Description

[0079]In an embodiment, the invention relates to a disposable device for microbial air sampling. The control of microbial contamination in environments wherein aseptic working conditions are required is extremely important, but not the sole aspect in the preparation of products such as drugs.

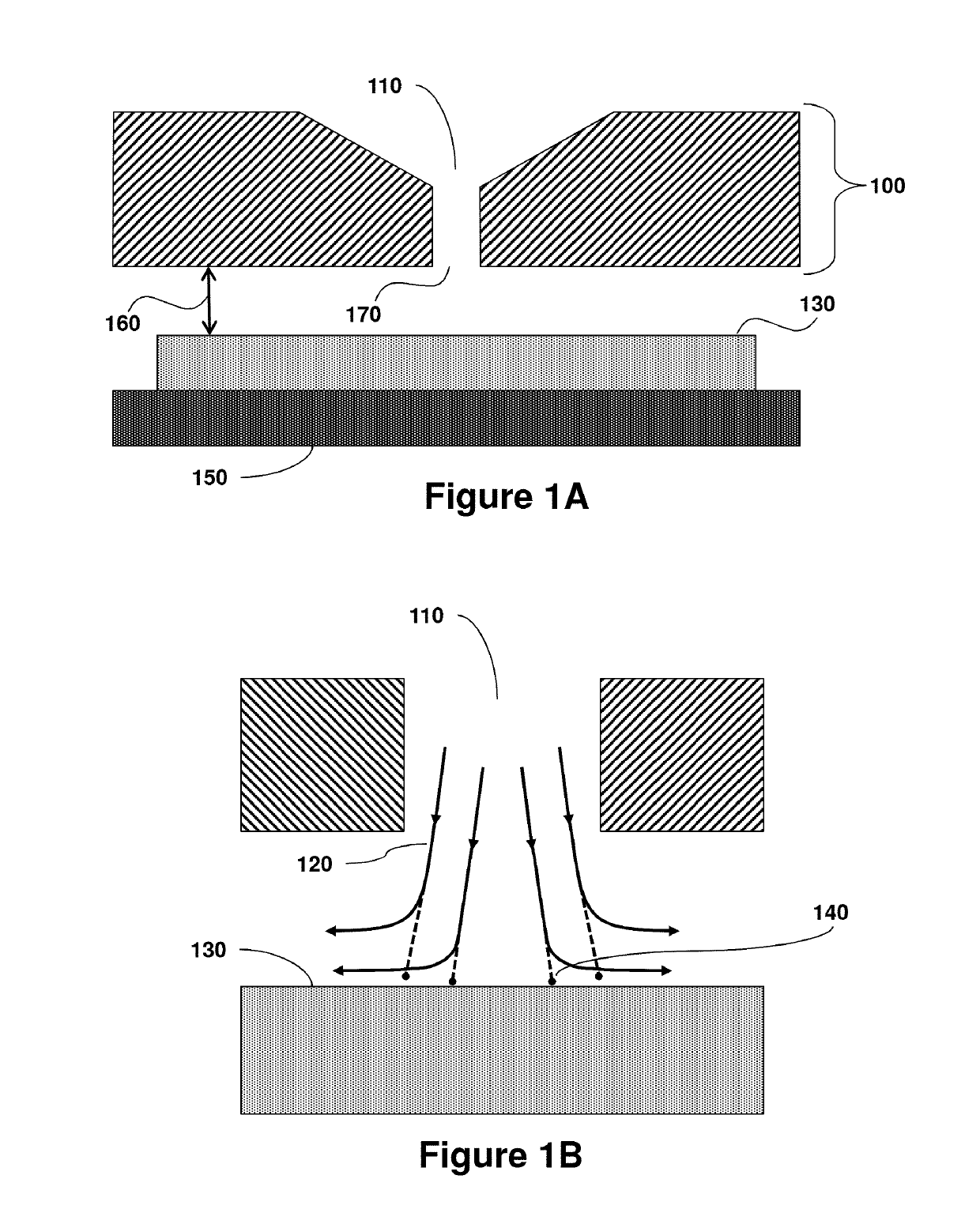

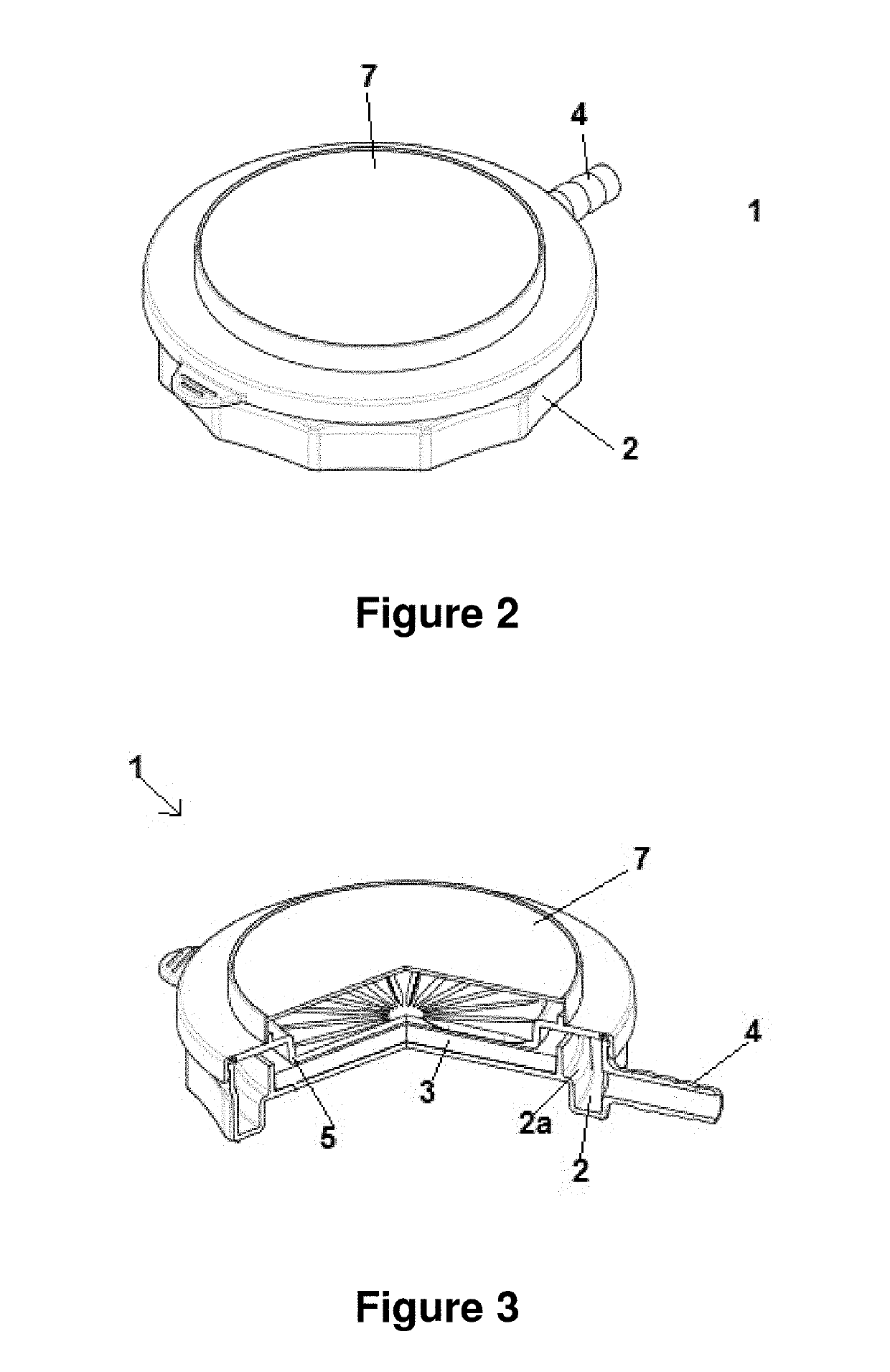

[0080]Several methods and devices are known for the control and / or quantification of contamination of air by microorganisms. These include impact devices or “impactors” principally consisting of a containment head within which is housed a Petri dish. Specifically, the principle on which the impactors are based is that the air to be analyzed is forced, by means of a suction pump, for example, in order to penetrate into the sampling head where, due to the impact with the culture medium of the Petri dish, the deposition of particles in the air on the same medium is guaranteed. In some devices, the Petri dish is placed inside the impactor whenever it is ne...

example 2

Single-Use Impactor Manufacturing Process

[0105]FIG. 6 provides a workflow diagram illustrating a method of making an impactor of the present invention. As shown in FIG. 6, the top pieces (e.g., sampling heads) are fabricated using a molding process, optically inspected using a camera for imaging and subsequently an O-ring seal is provided. As shown in FIG. 6, the bottom pieces (e.g., impactor bases) are fabricated using a molding process and inspected via batch sampling. After top and bottom pieces are manufactured, they are each sterilized via exposure to beta radiation. Next, a growth medium, such as agar, is provided to a growth medium container within the impactor base, and top and bottom pieces are subsequently assembled by engaging the O-ring seal between top and bottom pieces. The product is then packaged and sterilized via an additional beta irradiation process. The manufacture process may optionally further include quality control tests, e.g., batch sampling, of the growth ...

example 3

Impactor Devices For Sampling Biological Particles

[0106]FIGS. 7-11 provide additional schematic drawings illustrating exemplary impactor devices for sampling biological particles. These figures provide exemplary physical dimensions (millimeters), geometries and relative orientations of device components that are useful for certain applications. The specific parameters shown in FIGS. 7-11 are purely exemplary in nature and are not intended to limit the scope of the devices and methods disclosed herein. Devices of the invention are inclusive of a wide range of other physical dimension, geometries, orientations and other variations, as will be readily understood by one having skill in the art.

[0107]FIG. 7 provides a schematic providing a top view and cross sectional view of an impactor base of an impactor device of the invention. As shown in this figure, impactor base 500 comprises outlet 520 and container 510 for containing a growth media 530. In some embodiment, container 510 is a pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com