Wave-structured film beam polarizer

A polarizing device and wave-like technology, applied in the field of wave-like structure thin-film beam polarizers, can solve the problems of complex processing technology and high investment cost, and achieve the effect of wide selection of materials, low production cost and high degree of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

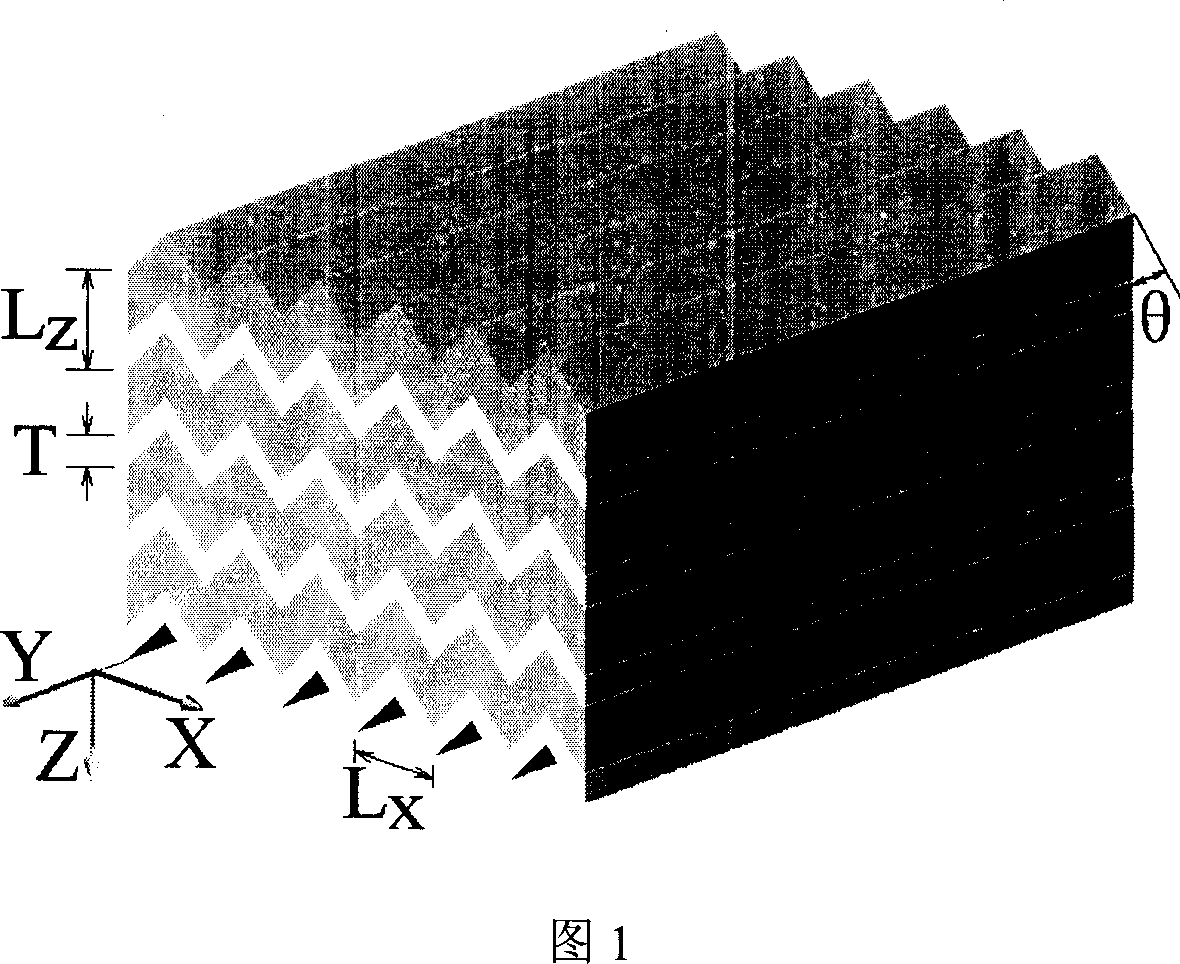

[0016] Example 1: Wavy Structure Thin Film Beam Polarizer at Normal Incidence

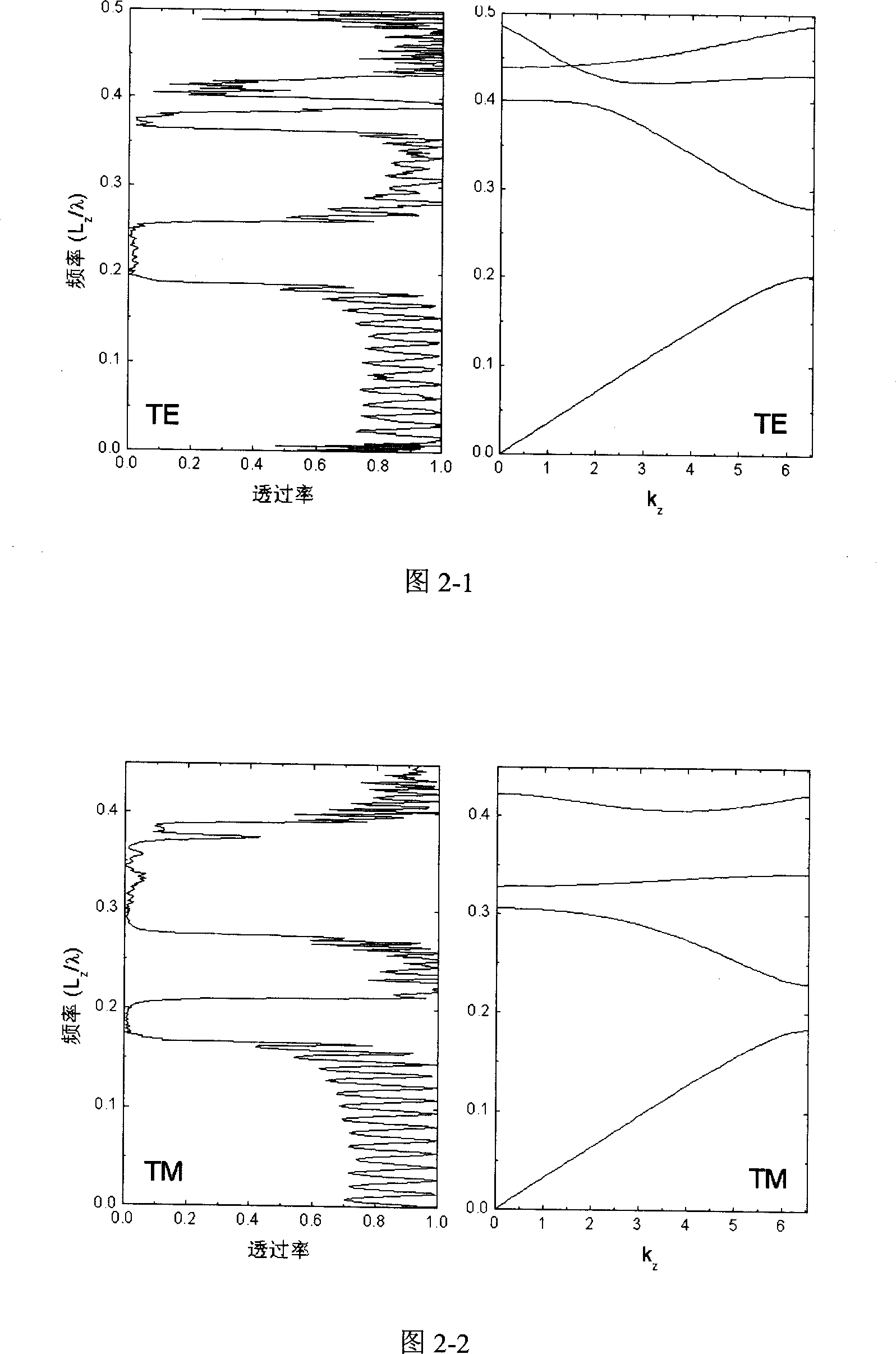

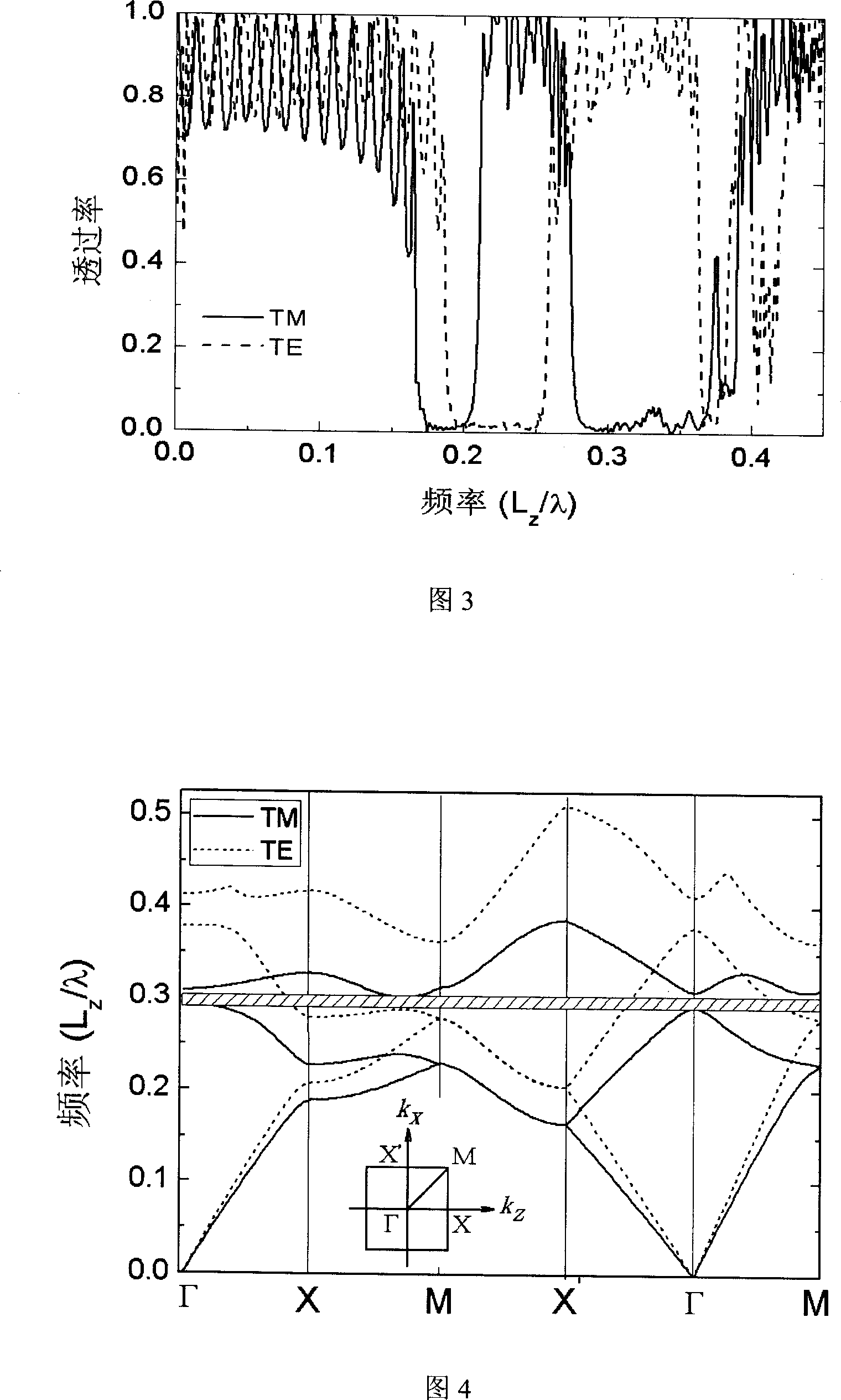

[0017] The wavy structure film is shown in Figure 1, and the period L of the film layer along the Z direction z Take it as 480nm, the thickness T of the high refractive index material is taken as 160nm, and the period L of the wavy structure along the X direction x Take it as 560nm, take the inclination angle θ of the wavy film layer as 45 degrees, and choose Si (n=3.5) and SiO as the two dielectric materials respectively. 2 (n=1.5), the beam is incident vertically along the Z axis. Figure 2 shows the transmission spectra of TE mode and TM mode and their corresponding energy band structures. Figure 3 shows the comparison of the transmission spectra of the two polarization states, at L z / λ=0.165-0.18 and L z / λ=0.275-0.36 In the two frequency bands, the TE mode is highly transparent and the TM mode is reflected. z / λ=0.21-0.255 In the frequency band, the TE mode is reflected and the TM mode is...

Embodiment 2

[0018] Example 2: Wave-structured thin-film beam polarizer at oblique incidence

[0019] The wavy structure film is shown in Figure 1, L z Take it as 440nm, T as 140nm, L x Take it as 560nm, take θ as 45 degrees, and choose Si(n=3.5) and SiO as the two dielectric materials respectively 2 (n=1.5). Figure 4 shows the energy band structure of TE mode and TM mode, and the complete band gap of TM mode is at L z / λ=0.29-0.30. On the boundary of the first Brillouin zone (that is, X-M-X'), the second energy band of the TE mode is located below the complete forbidden band of the TM mode, and any point connected to the center Γ on the boundary represents any wavy structure inside the film. For a wave vector direction, it is known that the eigenfrequencies of the TE mode corresponding to the Γ point and the point on the boundary are respectively above and below the complete forbidden band of the TM mode. The energy band must pass through the complete forbidden band of the TM mode. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com