Light and ultralight heavy-load radial-bearing radial-play measuring device

A radial clearance and measuring device technology, applied in mechanical clearance measurement, mechanical bearing testing, etc., can solve the problem that the radial clearance cannot be measured, it is not suitable for mass production measurement, and the accuracy of the measured value is affected by the stability of the gas source Sexual impact and other issues, to achieve the effect of simple structure, easy operation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

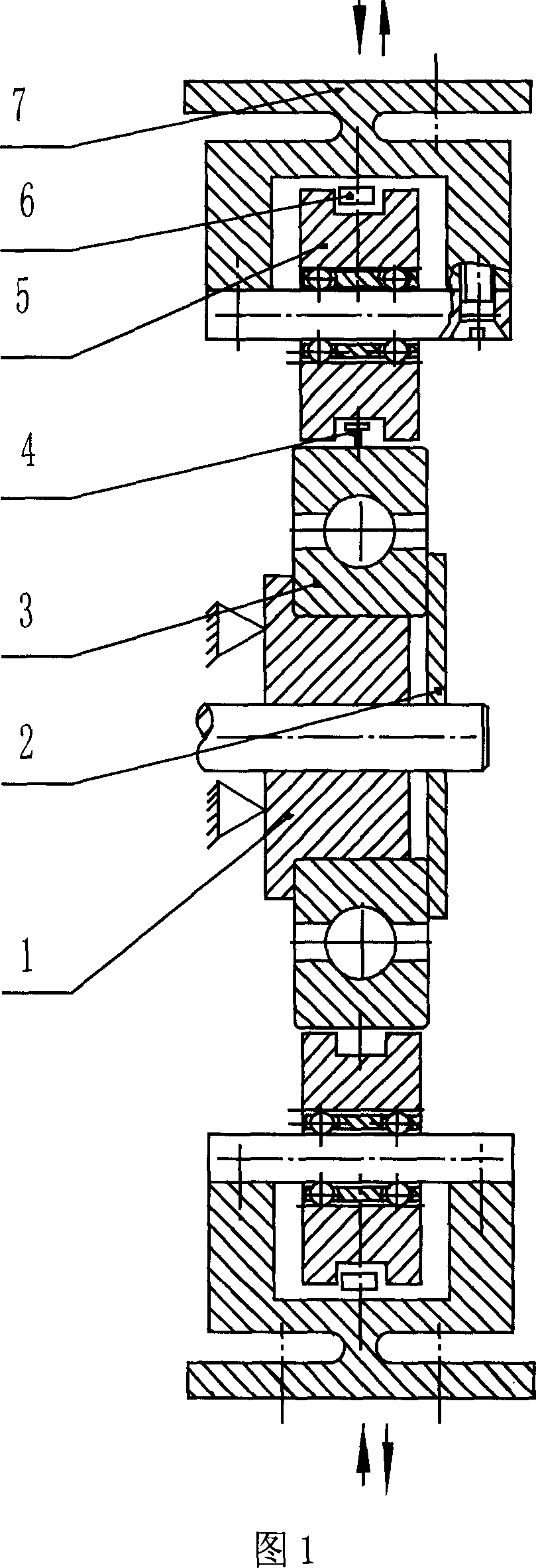

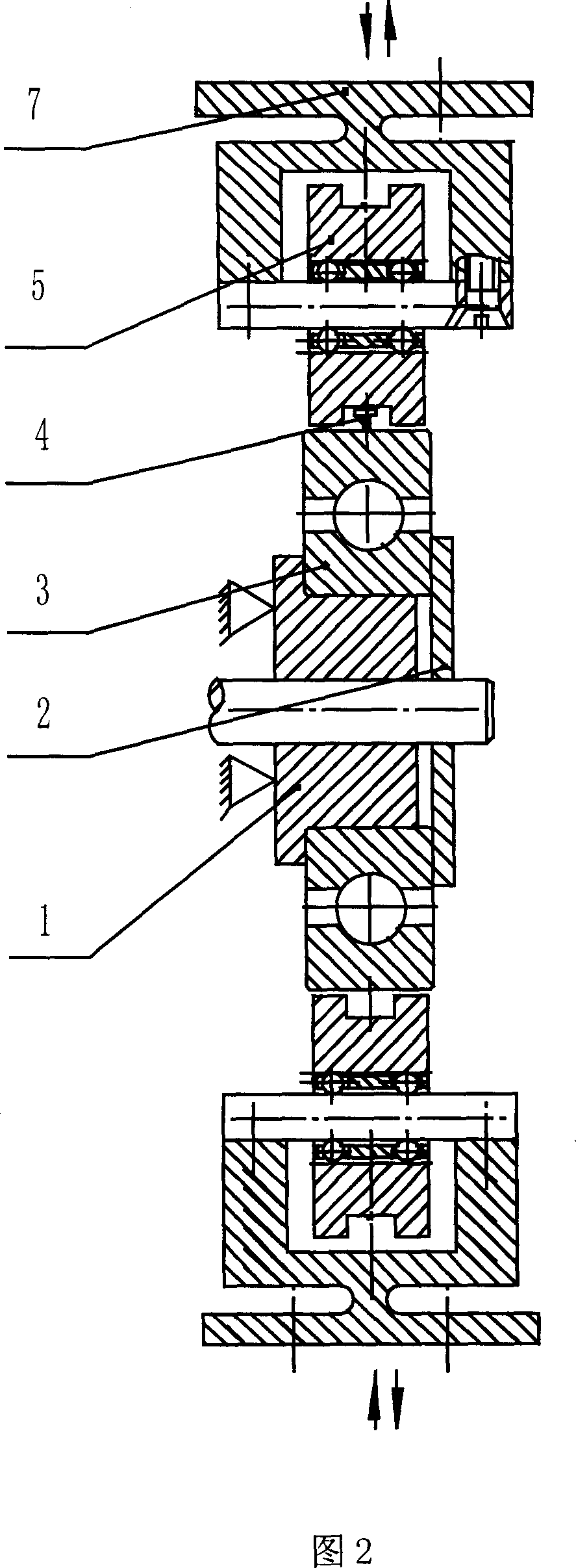

[0010] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0011] As shown in Figure 2: this embodiment is composed of a mandrel sleeve 1, a gland 2, a measuring rod 4, a pressure wheel 5 and a support 7, and the pressure wheel 5 is arranged between the support 7 and the bearing 3 to be tested. The axial clearance between the bearing 7 and the bearing 7 is 0.20-0.25mm, and the width of the groove on the pressure roller 5 is 3±0.01mm of the width of the measuring rod. The roughness of the width surface is Ra0.2μm, and the symmetry is controlled at 5μm based on the end surface (according to the ultimate load of the instrument, the minimum width of the measuring rod 4 is calculated). To meet the measurement of radial clearance of high-precision narrow series bearings.

[0012] The roughness of the outer diameter of the pressure roller 5 is Ra0.2μm, the outer diameter is φ30.5±0.015mm, the roundness and cylindricity are controlled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com