Method for producing surface antibiotic product using physical gas phase deposition technology

A physical vapor deposition, surface antibacterial technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of affecting the sputtering effect, the decrease of argon ion concentration, target poisoning, etc., to achieve simple process production Convenience, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Evaporation coating technology is used to coat the surface of the object with an antibacterial layer.

[0041] The coating technology is carried out in the existing activation reaction evaporation deposition device: the substrate is made of dry solid materials, such as metal materials, non-metal materials, fiber products, polymer materials, dry plant materials or leather materials, antibacterial Evaporation materials are selected from Ti, Zn, Ca, Si, Mg, Zr, Cd, As, Sb, Se, Ce, Re, Cu, Ag, Pb, Hg, Co, Ni, Al, Fe and their oxides, sulfides, One or more of nitrides and carbides are used in an amount of 0.01% to 100% of the weight of the entire film layer, and the reaction gas is O 2 , N 2 , NH 3 、CH 4 、C 2 h 6 or H 2 S.

Embodiment 2

[0043] The multi-arc plating technology is used to coat the surface of the object with an antibacterial layer.

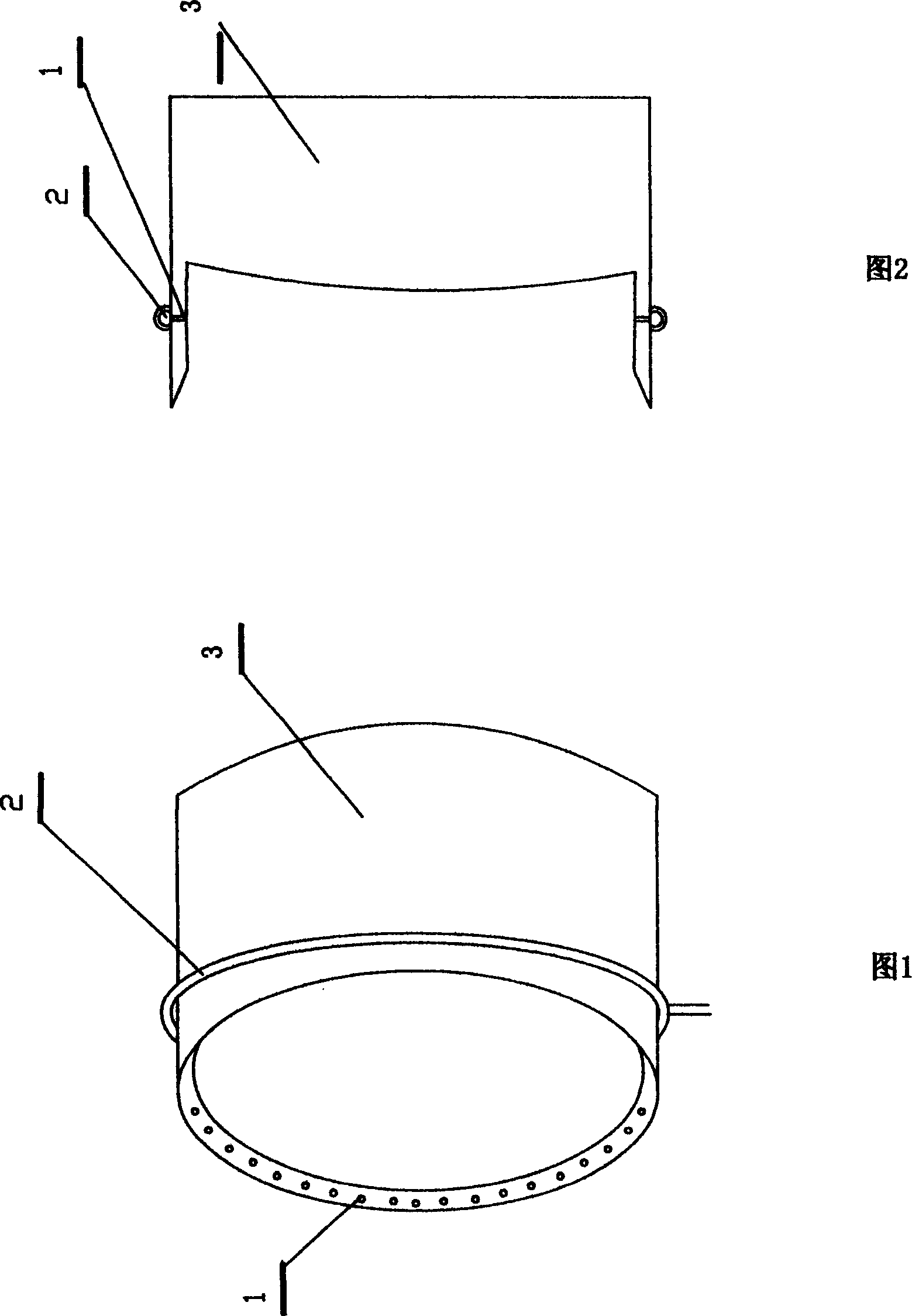

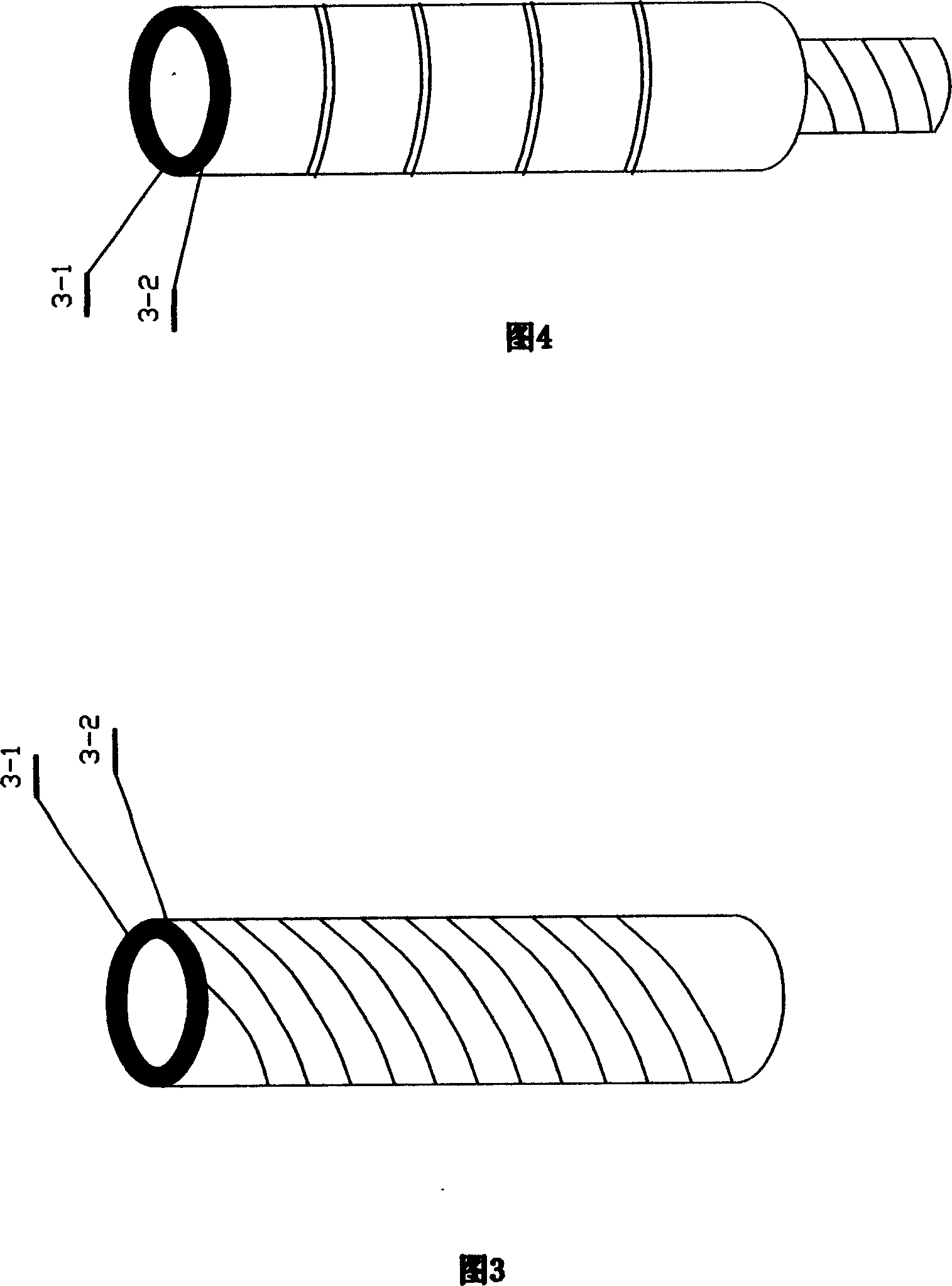

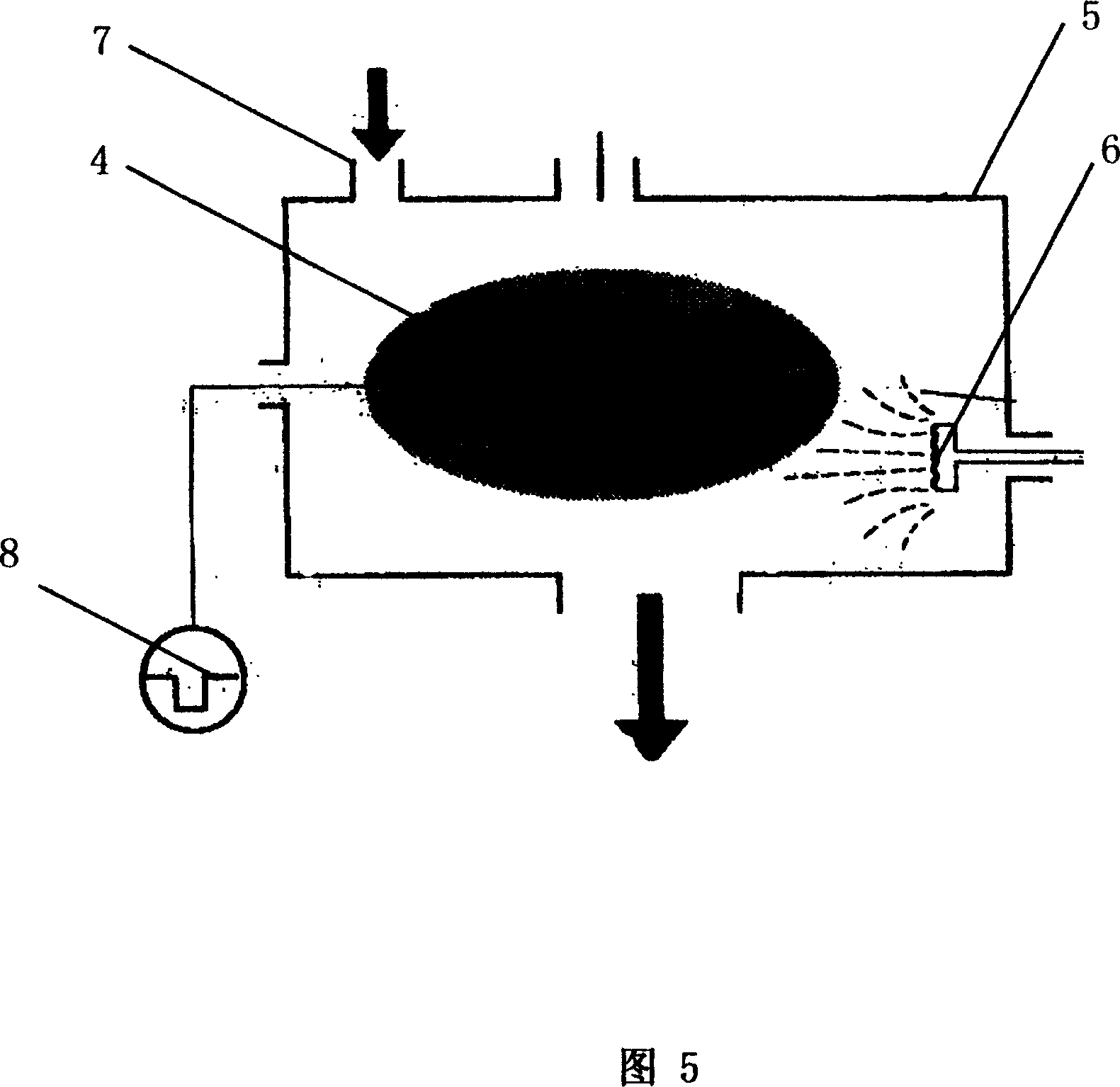

[0044] The coating technology is carried out in the existing multi-arc ion coating machine: the substrate is made of dry solid materials, such as metal materials, non-metal materials, fiber products, polymer materials, dry plant materials or leather materials, antibacterial The target materials are Ti, Zn, Ca, Si, Mg, Zr, Cd, As, Sb, Se, Ce, Re, Cu, Ag, Pb, Hg, Co, Ni, Al, Fe and their oxides, sulfides, One or more of nitrides and carbides are used in an amount of 0.01% to 100% of the weight of the entire film layer, as shown in Figure 1 and Figure 2. At this time, microscopic air holes need to be drilled on the antibacterial target 3 1, and use the air pipe 2 to pass the reaction gas into the air hole 1. In the multi-arc coating furnace, a magnetron sputtering antibacterial target is also provided, and the antibacterial target 3 is a cylindrical target. As shown i...

Embodiment 3

[0046] The surface antibacterial products were prepared by magnetron sputtering coating technology.

[0047] The coating technology is carried out in the existing magnetron sputtering ion coating machine: the substrate is made of dry solid materials, such as metal materials, non-metal materials, fiber products, polymer materials, dry plant materials or leather materials , the antibacterial target materials are Ti, Zn, Ca, Si, Mg, Zr, Cd, As, Sb, Se, Ce, Re, Cu, Ag, Pb, Hg, Co, Ni, Al, Fe and their oxides, sulfur One or more of compounds, nitrides, and carbides are used in an amount of 0.01% to 100% of the weight of the entire film layer. At this time, it is necessary to arrange a ventilation line on the surface of the substrate. And the antibacterial target material 3 is a cylindrical target, and this cylindrical target shown in Figure 4 is that the cylindrical target is made up of an inner core 3-1 made of a copper tube and an outer jacket 3-2 made of an antibacterial materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com