Device for transmitting torque

A technology of pulleys and components, applied in the direction of hoisting devices, portable lifting devices, components with teeth, etc., can solve problems such as noise, disadvantages, deformation of elastic parts, etc., to reduce the number, good free shape, Effect of backlash-free torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

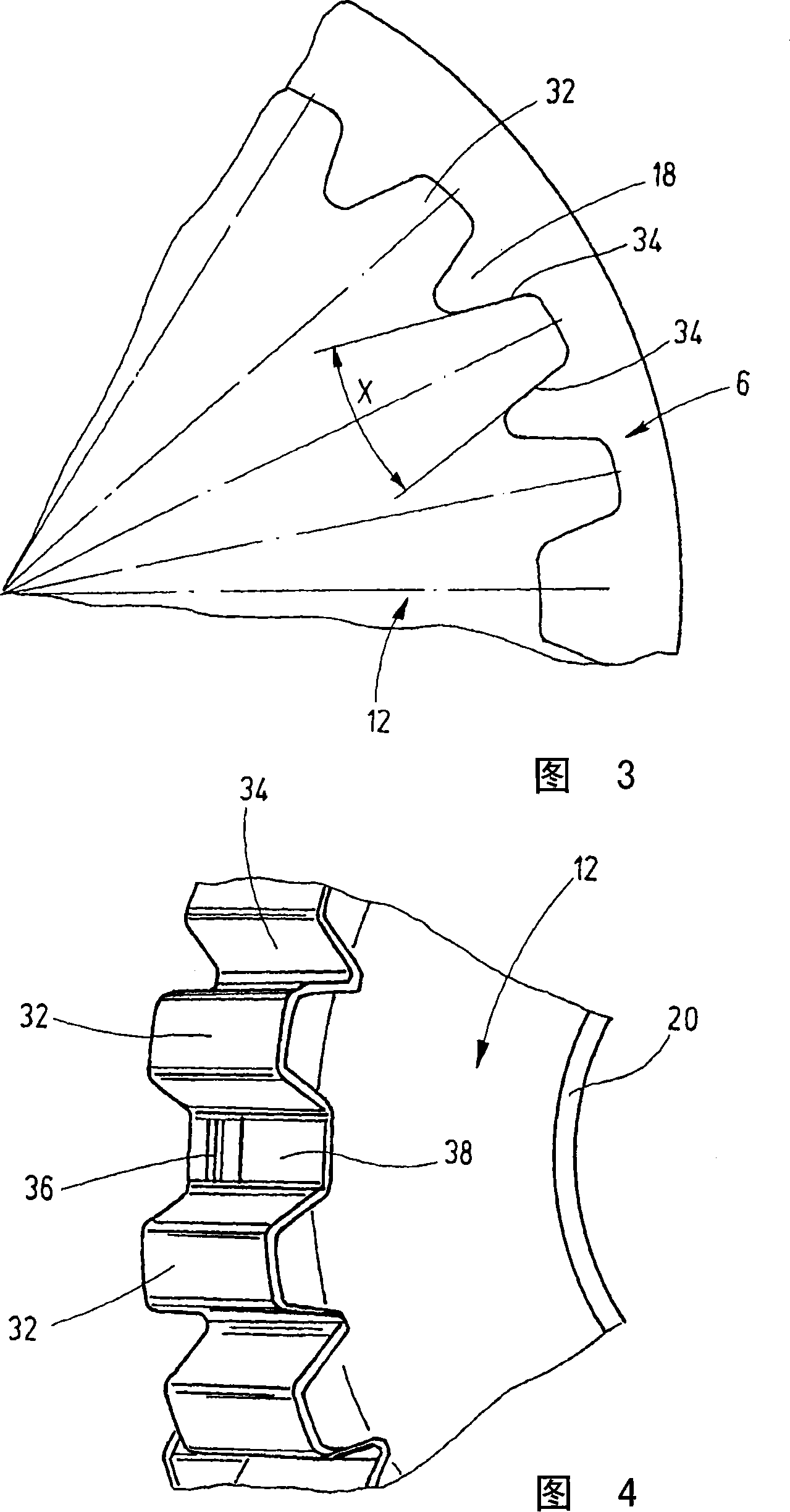

[0016] The embodiment of the device 2 for transmitting torque shown in the figure is part of the driving mechanism of the automobile air-conditioning compressor 4, which includes a pulley 6 driven by the automobile internal combustion engine (not shown) through a belt drive mechanism (not shown) , a hub 10 that is non-rotatably connected to the compressor shaft 8 of the air-conditioning compressor 4, and a substantially ring-shaped vibrator that is arranged between the pulley 6 and the hub 10 and that is non-rotatably connected with the hub 10 A damping element 12, the vibration damping element 12 serves to transmit the torque from the pulley 6 to the hub 10 and at the same time serves to damp vibrations.

[0017] The vibration damping element arranged between the pulley 6 and the hub 10 is not limited to the annular form as shown in Fig. 1 and Fig. 2, but may for example be star-shaped or other. Furthermore, the described or claimed device for transmitting torque is not limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com