Method for manufacturing white light diode with low attenuation

A manufacturing method and technology for diodes, which are applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of shortening the service life, waste, and no contribution to light emission, and achieve the effect of improving the life of the diode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

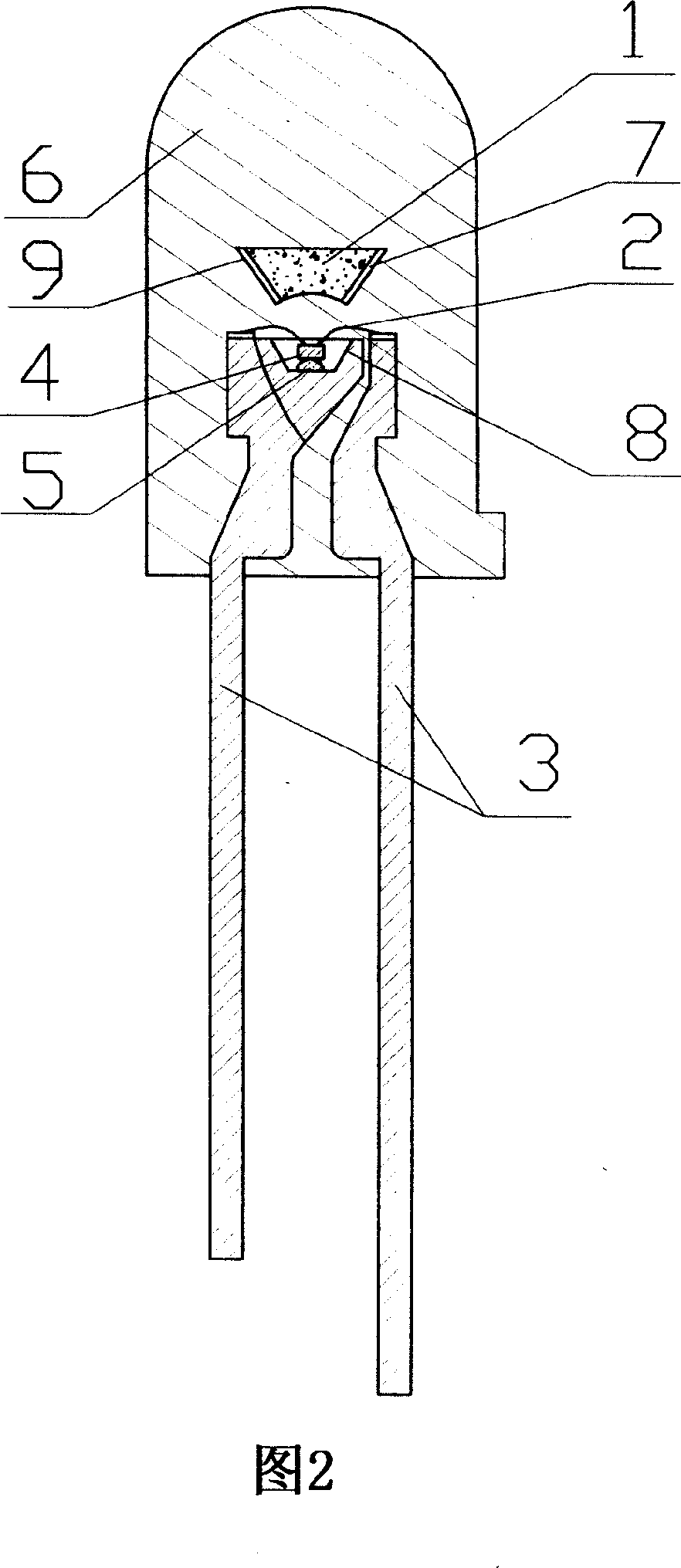

[0023] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

[0024] A support cup (9) is arranged at the support (3) upper end, and its elevation angle is between 5°-175°. The luminescent material (4) that the bottom of support cup (9) is bonded with adhesive (5), a bowl cup (8) is set on the support cup (9), and the included angle of bowl cup (8) should be with support cup (9) Match. There is a gap between the bowl cup (8) and the support cup (9), generally between 0.2mm-8mm, and this gap is filled by epoxy resin (6). A reflective substance (7) is arranged on the inner wall of the bowl (8), and a fluorescent substance (1) is arranged inside the bowl (8).

[0025] In this embodiment: the luminescent material is adopted, such as blue Gan. Reflective materials are used, such as optical films. The bonding material is silver glue or insulating glue. The fluorescent material adopts YAG.

[0026] The implementation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com