Yoke of rotary electric machine and manufacturing method thereof

A technology for rotating motors and manufacturing methods, applied in the field of yokes of magnetic circuits, can solve problems such as reducing heat capacity, reducing motor size or volume, and achieving the effect of reducing the overall quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A yoke 1 for a rotary electric machine and a manufacturing method thereof according to an embodiment of the present invention will be described with reference to FIGS. 1-5.

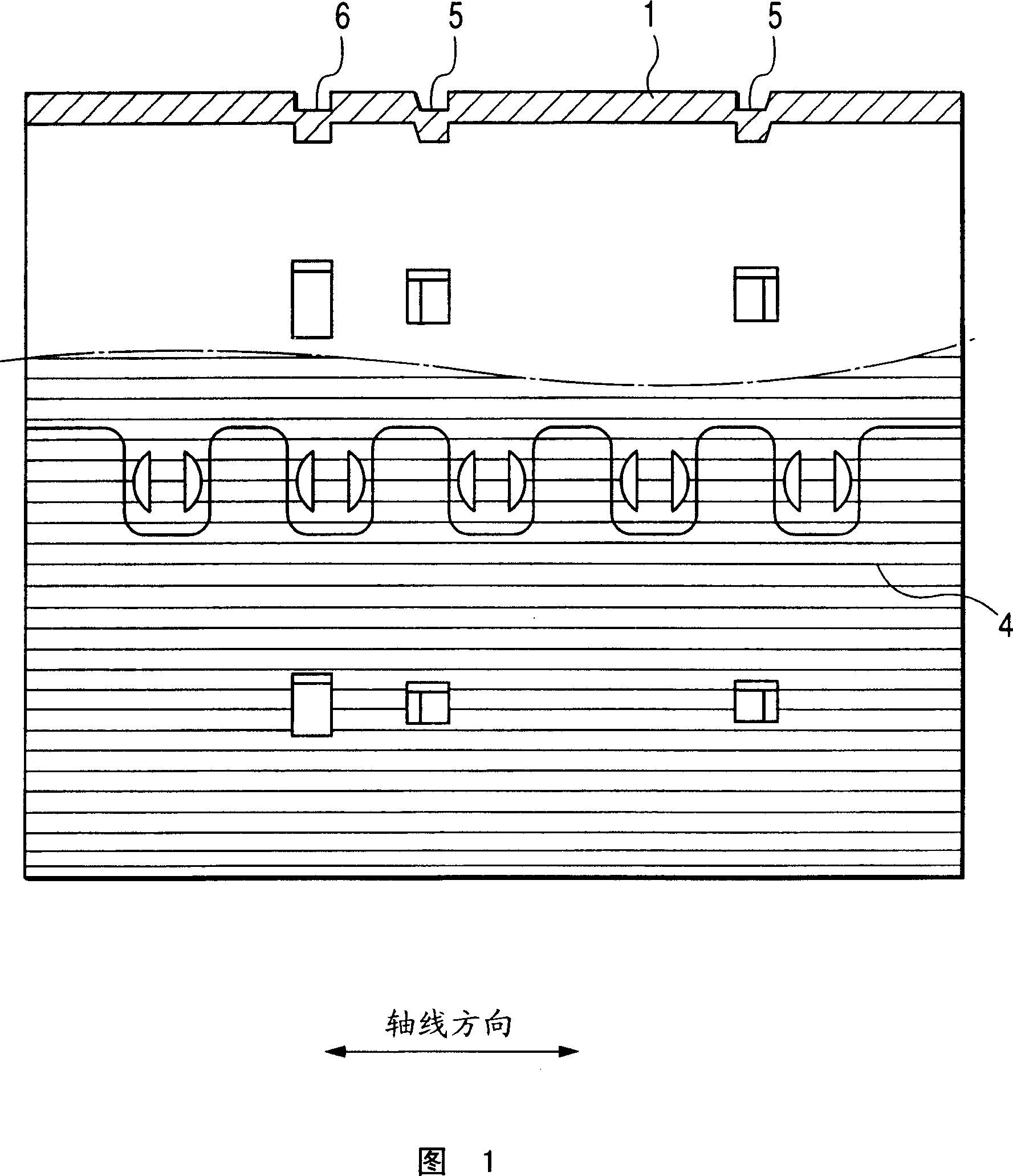

[0023] FIG. 1 is a side view of a yoke according to an embodiment of the present invention, and FIG. 1 also shows a partial sectional view of the yoke.

[0024] The yoke 1 of this embodiment forms, for example, a starter motor (as a rotary electric machine) that starts an internal combustion engine mounted on a vehicle.

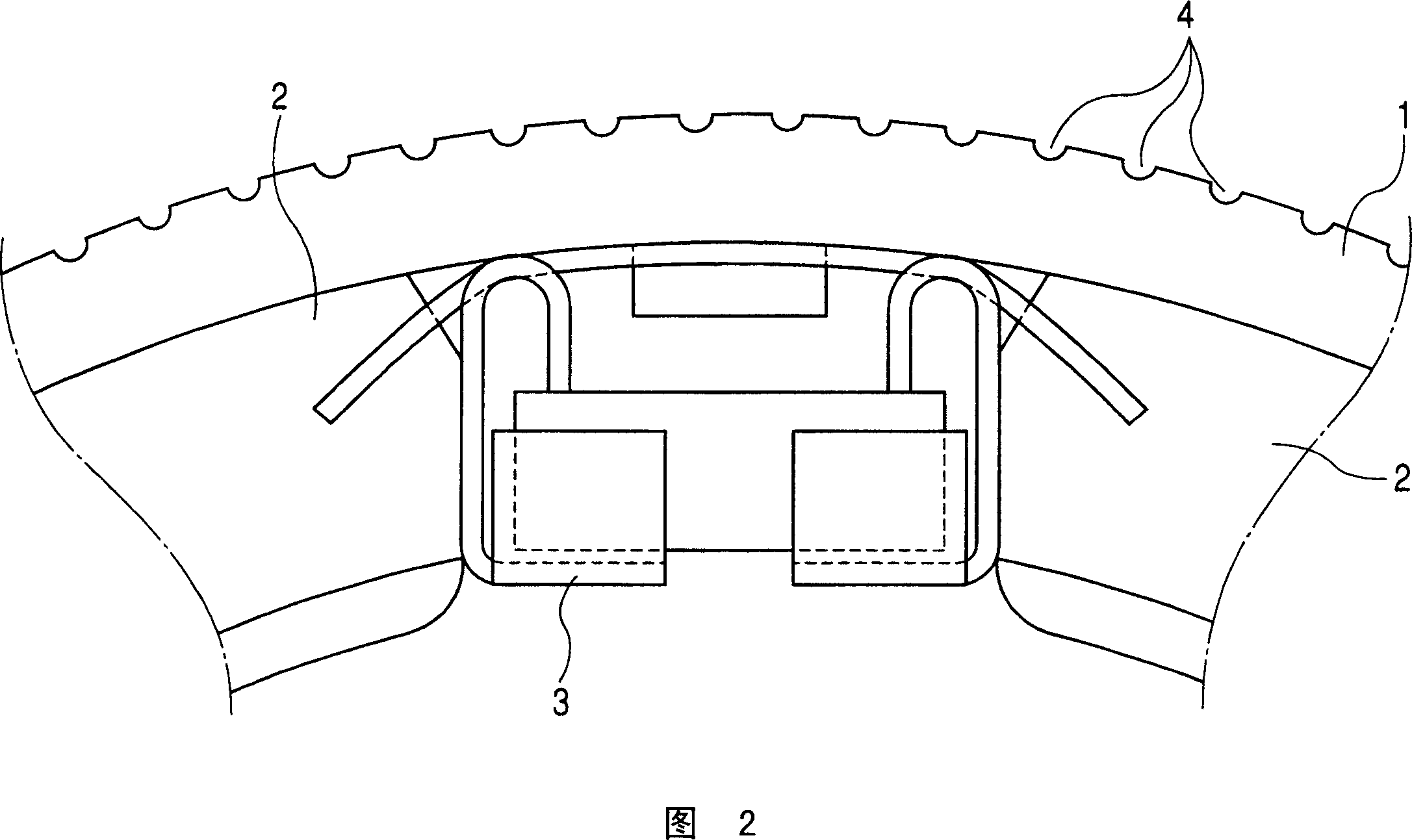

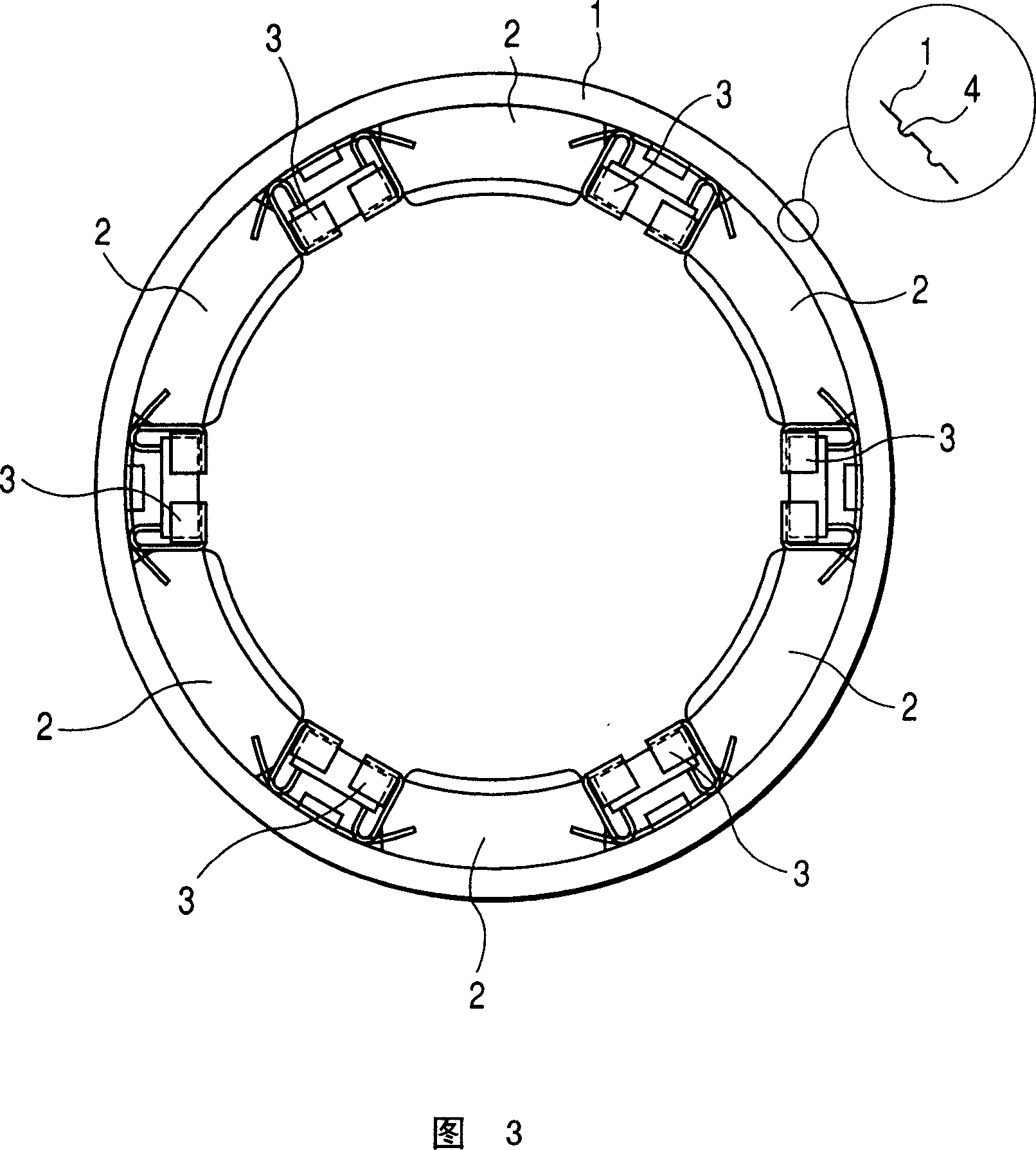

[0025] Fig. 3 is a plan view of the yoke assembled in the axial direction. As shown in FIG. 3 , a plurality of permanent magnets 2 are arranged and fixed on the inner periphery of the yoke 1 through magnet supporting members 3 . In particular, Figure 3 shows six permanent magnets 2 forming a yoke assembly as field magnets. As shown in FIG. 1 , a plurality of linear grooves 4 are formed on the outer peripheral surface of the yoke 1 at regular intervals along the entire periphery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com