Production of MDI-polyurethane microporous elastomer

A technology of microcellular elastomer and polyurethane, which is applied in the field of polyurethane microcellular elastomer preparation, can solve the problems of large dynamic fatigue deformation value of MDI-based microcellular elastomer products, and achieve optimization of physical and mechanical properties and improvement of dynamic fatigue deformation value , the effect of reducing randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

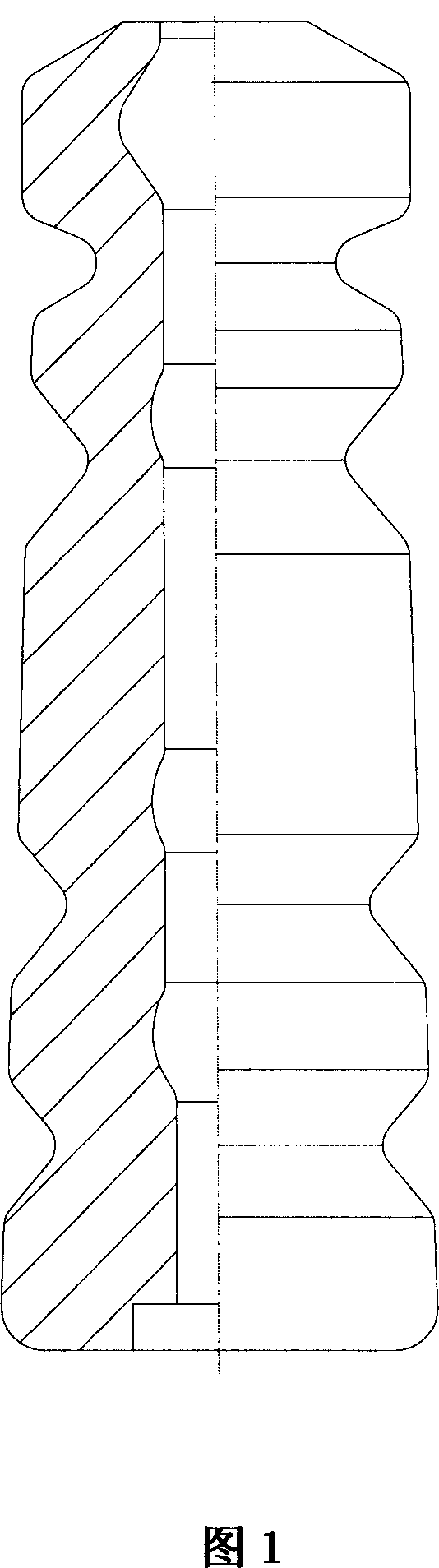

Image

Examples

Embodiment 1

[0026] Polytetrahydrofuran copolyether with a molecular weight of 2000 reacts with MDI at 70-90°C to obtain a prepolymer with a -NCO content of 6.2%. The chain extender component is mainly 1.4-butanediol, and the foaming agent, catalyst and surfactant account for 3% of the total;

[0027] Using a low-pressure foaming machine, mix the prepolymer and chain extender components according to the ratio of the isocyanate index to 100%, inject the reaction material liquid into a mold at 90°C to manufacture a microcellular elastomer test piece, and demould after 15 minutes. After aging at 110° C. for 15 hours.

[0028] The tested static mechanical properties are the same as in Comparative Example 1.

[0029] The measured dynamic fatigue performance is the same as that of Comparative Example 1.

[0030] The test results are shown in Table 1.

Embodiment 2

[0032] Polycaprolactone with a molecular weight of 2000 reacts with MDI at 70-90°C to obtain a prepolymer with an -NCO content of 7.8%. The chain extender component is mainly 1.4-butanediol, and the foaming agent, catalyst, and surfactant account for 5% of the total; a low-pressure foaming machine is used to mix the prepolymer and For the chain extender component, inject the reaction liquid into a mold at 90°C to make a microporous elastomer test piece, demould it after 15 minutes, and post-cure at 110°C for 15 hours.

[0033] The tested static mechanical properties are the same as in Comparative Example 1.

[0034] The measured dynamic fatigue performance is the same as that of Comparative Example 1.

[0035] The test results are shown in Table 1.

Embodiment 3

[0037] Polycaprolactone with a molecular weight of 2500 reacts with MDI at 70-90°C to obtain a prepolymer with an -NCO content of 9.5%. The chain extender component is mainly 1.4-butanediol, and the foaming agent and catalyst surfactant account for 8% of the total; a low-pressure foaming machine is used to mix the prepolymer and extender according to the ratio of isocyanate index to 100%. For the chain agent component, inject the reaction material liquid into a mold at 90°C to make a microporous elastomer test piece, demould after 15 minutes, and post-cure at 110°C for 15 hours.

[0038] The tested static mechanical properties are the same as in Comparative Example 1.

[0039] The measured dynamic fatigue performance is the same as that of Comparative Example 1.

[0040] The test results are shown in Table 1.

[0041] Table 1: Static and dynamic mechanical properties of the microcellular elastomers prepared in comparative example 1 and examples 1-3

[0042] serial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com