Rubber-reinforcing polyester cord and method for producing the same

A technology for polyester cords and manufacturing methods, applied in the field of crown ply cords, can solve problems such as not necessarily having mechanical properties, and achieve the effects of high elastic rate, heat-resistant bonding and strength retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

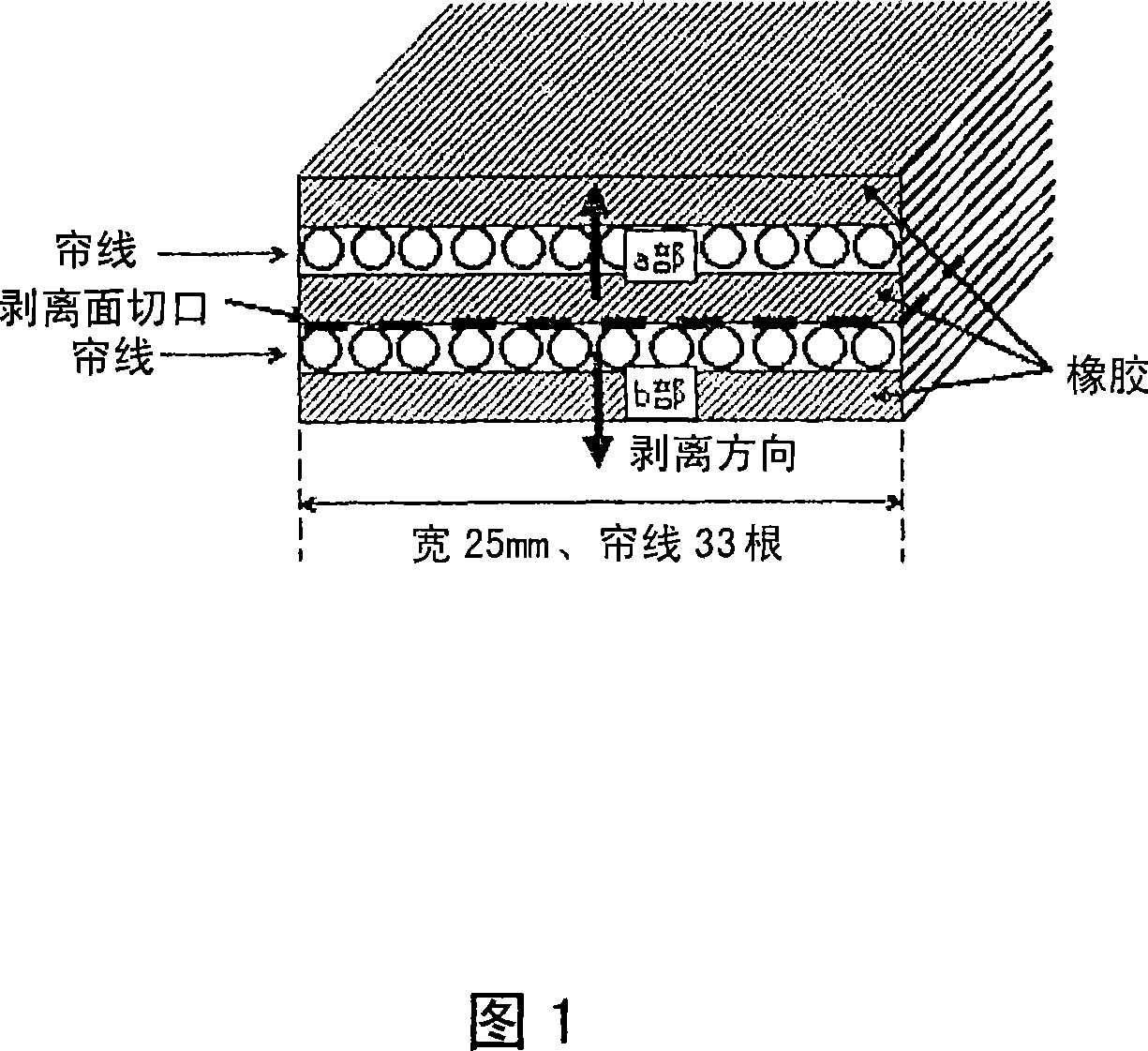

Image

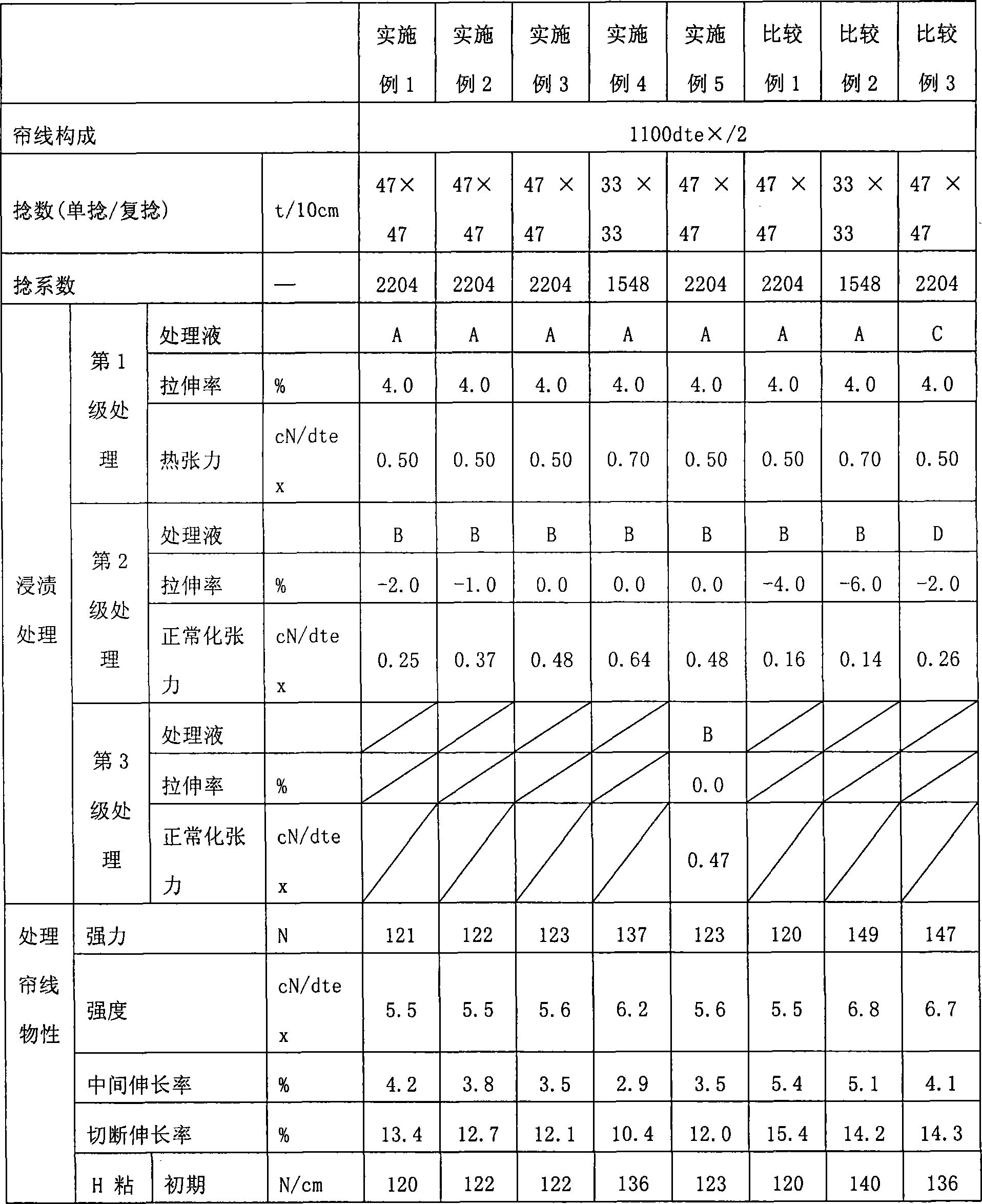

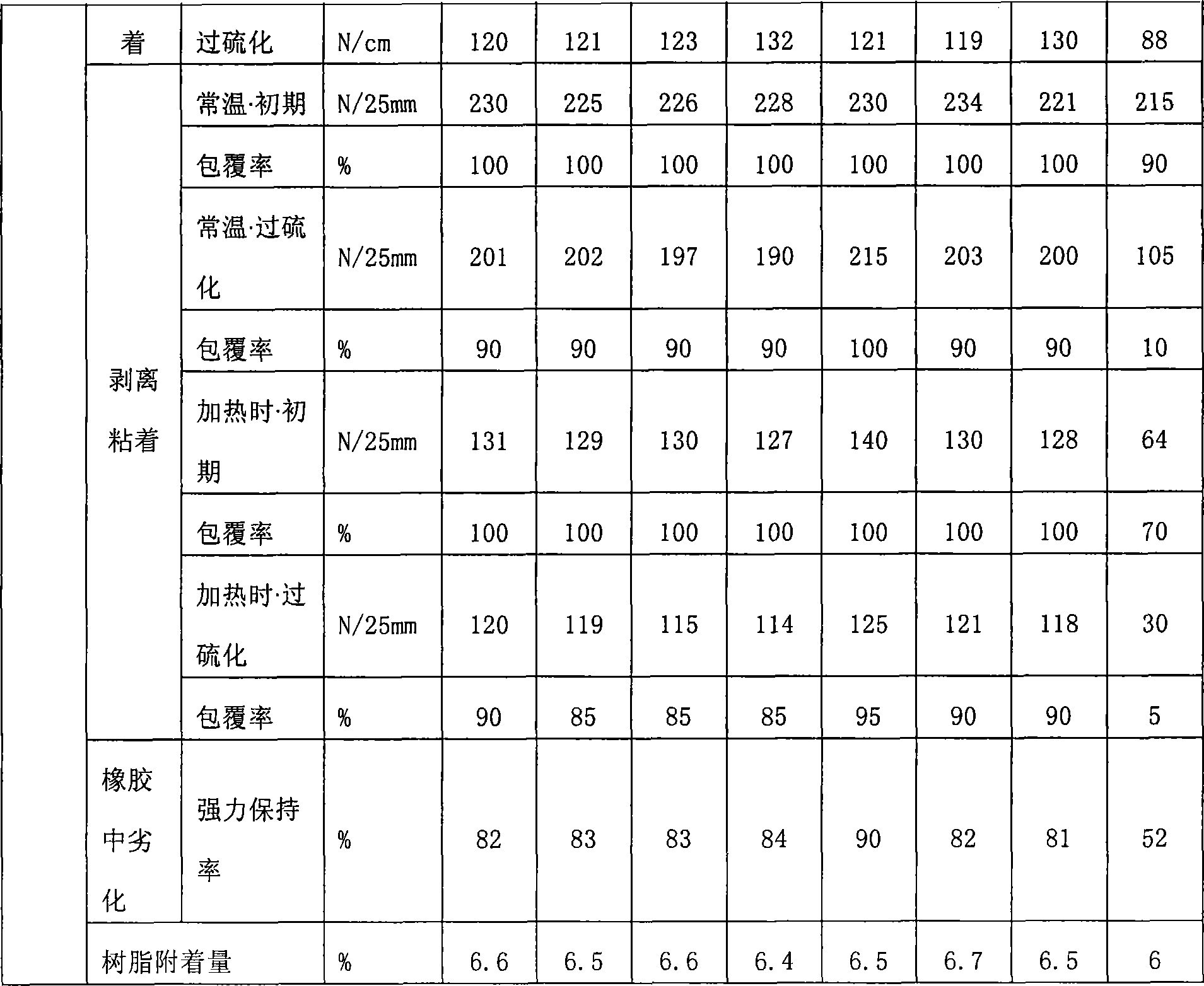

Examples

Embodiment 1

[0068]Polyethylene terephthalate chips with an intrinsic viscosity of 0.95dl / g are melted and sprayed from a spinneret with 190 holes at a spinning temperature of 300°C, passed through a heating zone of 320°C, and then processed by 20 The cooling wind at ℃ cools and solidifies it, draws it at a spinning speed of 550m / min, and then stretches it with a draw ratio of 5.8 times, and imparts sorbitol polyglycidyl ether as an epoxy compound to make it relax. 3.0% after coiling. 2 strands of polyethylene terephthalate precursors (intrinsic viscosity 0.88dl / g, strength 8.3cN / dex) obtained in this way of 1100dex, 190 filaments are ply twisted to obtain a twist number of 47×47(t / 10cm) billet line.

[0069] This cord was immersed in 1 treatment solution, and the cord soaked in the treatment solution was wrung with a squeeze roller with adjusted pressure to remove excess solution. Then, the cords to which the treatment liquid was applied were dried in an oven at 120° C. for 56 seconds ...

Embodiment 2

[0072] In the treatment of Example 1, the relaxation rate during drying and heat treatment after application of the second treatment liquid was changed to -1.0%. The normalized tension at this time is 8.1N / cord (0.37cN / dtex). Except for this, the immersion treatment was performed using the same strand and treatment liquid as in Example 1.

Embodiment 3

[0074] In the treatment of Example 1, the relaxation rate during drying and heat treatment after application of the second treatment liquid was changed to 0%, and the normalized tension at this time was 10.6 N / cord (0.48 cN / dtex). Except for this, the immersion treatment was performed using the same strand and treatment liquid as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com